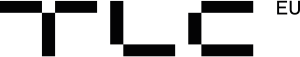

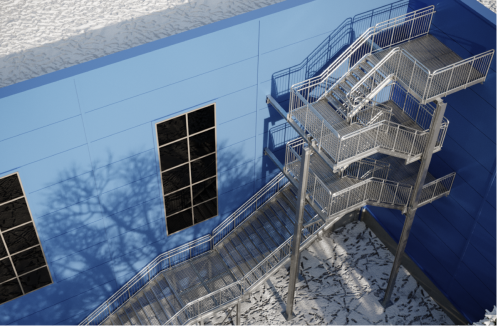

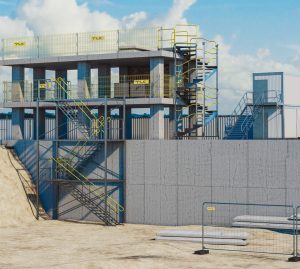

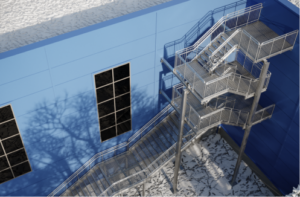

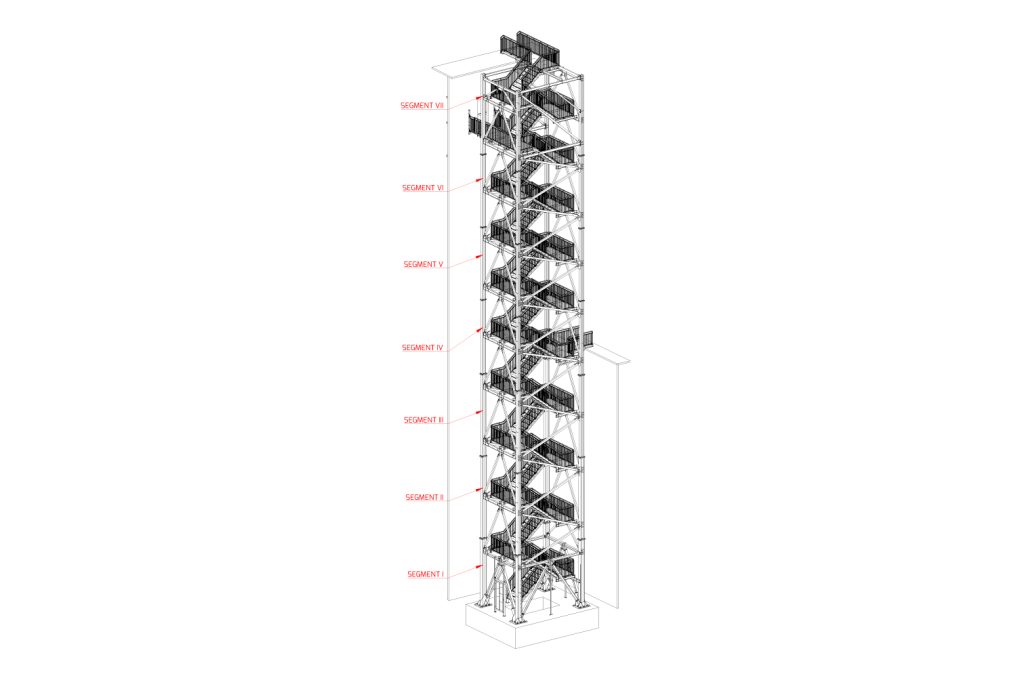

Steel staircase for a food industry facility in Poland

Read our other news

TLC EU named a Forbes Diamonds 2026 laureate – another consecutive year among the fastest-growing companies

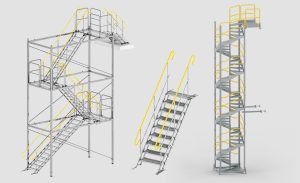

From design to installation – comprehensive support for demanding industrial projects