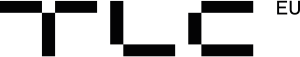

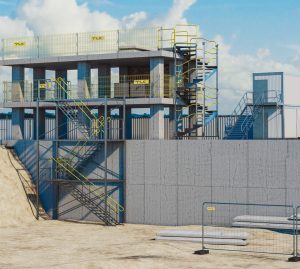

Steel staircase for a food industry facility in Poland

Project number: E/3250

Location: Nowy Modlin, Poland

Industrial steel staircases – safe access and compliance with standards

One of the most modern logistics facilities for the food industry in Europe has been designed in Nowy Modlin near Warsaw – an automated refrigerated warehouse with an area of 27,000 m² and a capacity of 95,000 pallet spaces.

As part of this project, TLC delivered a steel staircase for a modern food industry facility. The structure provides access to two building levels and complies with all applicable safety regulations.

TLC steel staircases – reliable access systems

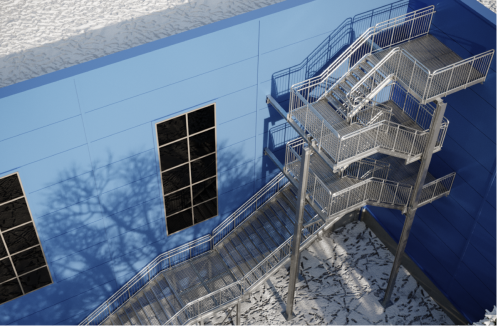

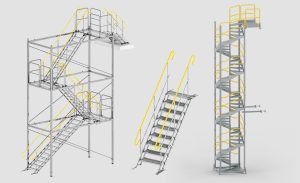

TLC steel staircases form versatile access systems that may include:

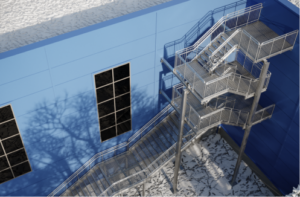

Thanks to modular prefabrication, staircases can be installed in production halls, logistics warehouses, cold stores, food processing plants, sorting facilities, and public buildings. Installation is carried out using bolted connections or as a self-supporting structure based on columns.

TLC contribution – 38.7 m high staircase with hot-dip galvanizing

For this investment, TLC designed and manufactured a steel staircase with a total height of 38.7 m and a weight of 39.1 tones. The entire scope – from detailed design, through in-house production in machine park, to on-site installation – was carried out directly by TLC. Thanks to this comprehensive approach, the investor avoided the risks of splitting the work between several contractors, saving time, costs, and eliminating potential delays.

Key technical parameters:

- Steps: welded gratings 34 × 38, DIN 51130: R10 (anti-slip)

- Balustrade: child-safe, handgrip made of circular pipe ø42,4, railposts made of circular pipe ø42,4, two followers made of circular pipe ø26,9, filling of vertical round bars ø12,

- Corrosion protection: hot-dip galvanizing (acc. to ISO 1461)

- Structure: prefabricated segments with intermediate landings

- Access protection: a lockable gate was installed at the base of the staircase to secure the entrance

Hot-dip galvanizing ensures corrosion resistance and long service life with minimal maintenance costs, which is especially important in the food industry. The structure was designed in compliance with Polish and European standards (PN ISO 14122) ensuring safe access and long-term durability.

Advantages of steel staircases in food industry facilities

The staircase designed and manufactured by TLC provides a safe escape route, tailored to the specific requirements of the food industry, proving the benefits of industrial steel staircases in large-scale facilities. Its hot-dip galvanized finish ensures long-term protection against corrosion, offering a structure with an extended service life and minimal maintenance needs.

The staircase is equipped with anti-slip steps that guarantee secure footing in all conditions and child-safe balustrade with vertical infill, increasing overall user safety. The modular construction system enables fast on-site assembly and easy adaptation to the architectural layout of the facility, significantly reducing installation time.

By meeting all relevant fire safety regulations and occupational health and safety standards, the solution not only provides safe access but also ensures full compliance with legal and industry-specific requirements.

Technical specifications and structural details of the steel staircase

To ensure maximum durability and stiffness, the structure uses preloaded bolted connections with HV sets (acc. to EN 14399). High-strength M22 bolts, complete with washers and nuts in compliance with European standards, were tightened to a preload of 212 kN (approx. 21.6 tons per bolt). Such connections prevent loosening under load and vibrations, ensuring long-term stability of the staircase in demanding industrial conditions.

Project details

- Height: 38.7 meters

- Weight: 39.1 tones

- Steps: welded gratings 34 × 38, DIN 51130: R10

- Balustrades child-safe, vertical round fars fi 12

- Protection: hot-dip galvanizing

- Construction: 7 segments

TLC steel staircases for industrial facilities

This project confirms that TLC modular steel staircases meet the highest requirements for safety, durability, and compliance with standards. The staircase for the food industry facility in Nowy Modlin is an example of a reliable solution for large industrial buildings.

Looking for a compliant steel staircase for your investment?

Contact TLC – we will prepare a solution tailored to your needs.

See our other projects

External spiral staircase and service platforms for industrial tanks

Comprehensive system of aircraft maintenance platforms