External spiral staircase and service platforms for industrial tanks

Project: 9/3763

Safe access to industrial storage tanks

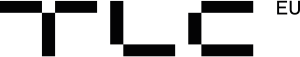

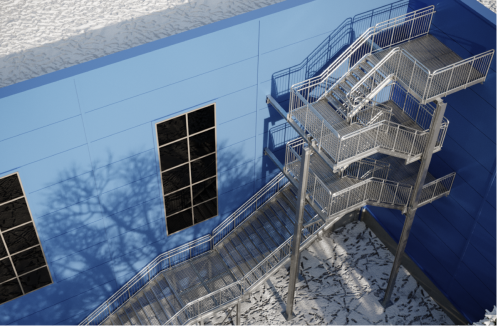

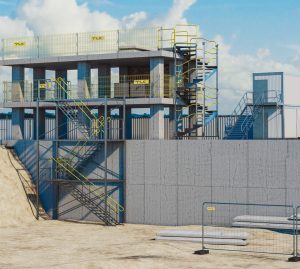

In collaboration with a manufacturer of stainless steel storage tanks we delivered a complete system consisting of an external galvanized steel spiral staircase and service platforms for two industrial tanks. The solution was designed to ensure safe access for daily operation and scheduled maintenance work, in full compliance with EN ISO 14122 requirements for industrial stairs and walkway systems.

External steel spiral staircase – technical specifications

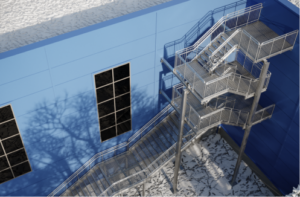

The access system includes a full-height spiral steel staircase integrated with service platforms positioned at several operating levels. The staircase is made of S235 steel and protected with hot-dip galvanizing (acc. to ISO 1461) to guarantee corrosion resistance and long service life in outdoor conditions.

The staircase reaches a total height of 30,860 mm with a 1,250 mm radius (2,000 mm diameter). One full rotation contains approximately 16.4 steps. The steps and platforms are filled with 30×30×3 mm grating, ensuring high slip resistance. The handrails follow a child-safe design, manufactured according to GPI specification 0720-001 and galvanized for durability. The structure was executed in EXC2 class (EN 1090-2) with a load capacity of 5 kN/m² for both steps and platforms.

The complete layout includes eight intermediate landings and three service platforms, providing comfortable access to key technological elements along the tank height. To increase stability, support brackets and bracings were welded directly to the tank shell.

Project details:

Project: 9/3763

Type of structure: external spiral staircase and service platforms

Anti-corrosion protection: hot-dip galvanization, S235 steel

Location: Slovakia

Tank service platforms – durability, ergonomics and operational safety

The delivered tank platforms and external stairway system ensure efficient access at heights exceeding 30 metres while maintaining a compact footprint. Slip-resistant grating and child-safe balustrades improve user safety, even in demanding weather conditions. Additional bracings welded to the tank increase rigidity, which is essential for tall industrial structures exposed to vibrations and dynamic loads.

Hot-dip galvanized spiral staircase – durability and long service life

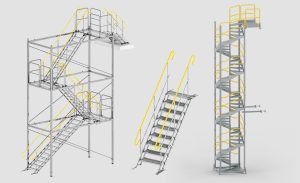

All components of the staircase and platforms were manufactured in the TLC production plant using laser cutting, automated welding and hot-dip galvanizing.

These processes ensure dimensional precision, repeatability and long-term resistance to corrosion, resulting in a robust galvanized steel spiral staircase and durable tank working platforms.

Comprehensive delivery – from design to installation

TLC provided the full delivery scope, including:

• technical design and 3D model

• steel structure manufacturing in EXC2 execution class

• hot-dip galvanizing in our TLC facility

• transport and installation at the site

This project is an example of a complete, consistent solution – from concept to installation – ensuring technical reliability, shorter lead times and high operational safety.

If you need a similar solution, contact us — we will design and manufacture an access system tailored to your facility.

See our other projects

Steel staircase for a food industry facility in Poland

Comprehensive system of aircraft maintenance platforms