TLC steel service platforms – safe access to evaporator units at Nordic Sugar Nakskov

Project number: C/3118

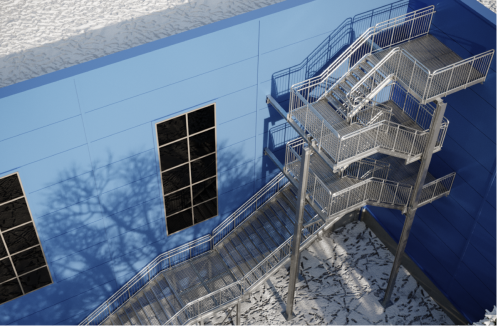

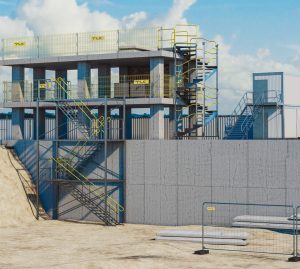

In our role within the Nordic Sugar Nakskov project in Denmark, we not only conducted detailed site measurements but also devised practical and functional solutions perfectly tailored to the factory’s specifications. Our platforms and staircases served as crucial infrastructure and were designed with a focus on efficient performance.

Throughout this project, we provided comprehensive support, starting from measurements, through design, all the way to production and transportation. The platforms were installed by Świdnicka Fabryka Urządzeń Przemysłowych, the company supplying evaporators on which our platforms were mounted. The entire process was carried out specifically for Nordic Sugar Nakskov, ensuring an ideal fit for the needs of the respective factory.

Key project features for Nordic Sugar

Location: Nordic Sugar Nakskov, Denmark

Purpose: To ensure safe and ergonomic service access to four evaporator units at heights of up to 21.6 m.

Applied standards: Full compliance with EN ISO 14122 (machine safety) and ISO 1461 (hot-dip galvanizing).

Key technology: Modular steel structure designed in 3D, ensuring precision and fast installation.

How do service platforms support efficiency in the food industry?

Falling-film evaporator units are essential equipment in sugar production, used for concentrating sugar juice. Our steel service platforms provide employees with safe and convenient access to key components such as heating tubes, juice distributors, and steam collectors. This enables efficient inspection and maintenance across all levels, resulting in more ergonomic, safer, and more efficient operation of the entire facility.

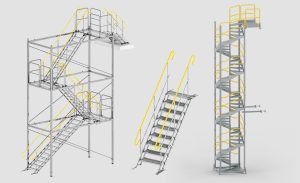

Why do our modular platforms guarantee safety and flexibility?

We design our access structures in accordance with EN ISO 14122, ensuring the highest level of safety.

The main advantages include:

- Corrosion resistance: Thanks to hot-dip galvanizing according to ISO 1461, the platforms are perfectly suited to environments with high humidity and temperature.

- Fast installation: The modular design significantly shortens on-site assembly time.

- Perfect fit: The flexibility of the system allows precise adaptation to the dimensions of the evaporator units and the existing plant infrastructure.

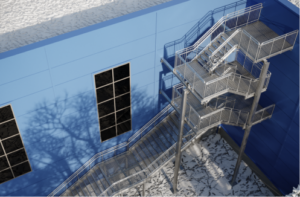

How does 3D design ensure accurate fit and efficient installation?

All platform and stair components were developed as three-dimensional 3D models. This approach ensured precise adaptation of the structure to the evaporator units and the plant environment. Integrating digital models with technical documentation minimizes the risk of design or fabrication errors, ensuring smooth and trouble-free installation. In this project, the installation was carried out by our partner – Świdnicka Fabryka Urządzeń Przemysłowych, ensuring perfect synergy and the highest safety standards.

A proven solution for industry – summary

The project for Nordic Sugar Nakskov is an example of how our steel service platforms combine safety, durability, and ergonomics. By applying certified solutions such as ISO 1461 hot-dip galvanizing, compliance with EN ISO 14122, and anti-slip gratings, TLC structures provide a reliable and safe choice for the most demanding industrial sectors.

Frequently Asked Questions (FAQ)

1. Are TLC platforms resistant to harsh industrial environments?

Yes. Our steel structures are protected against corrosion through hot-dip galvanizing according to ISO 1461, ensuring long-term durability even in humid and high-temperature conditions typical for the food industry.

2. How do you ensure installation precision?

We design using 3D modelling technology. This enables virtual alignment of the platform with existing machinery and plant infrastructure, minimizing the risk of errors during final assembly.

We are certified to EXC3 according to EN 1090 and maintain continuous quality control and an FPC system, ensuring reliable and high-performance structures.

3. Do your platforms meet safety standards?

Our access systems — including steel service platforms and stairs — are designed and manufactured in full compliance with the EN ISO 14122 international standard, which defines safety requirements for permanent means of access to machinery.

Want to learn how our access structures can improve your industrial project?

Contact our team and discover solutions tailored to your needs!

Gallery

See our other projects

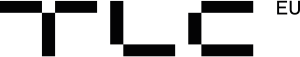

Steel staircase for a food industry facility in Poland

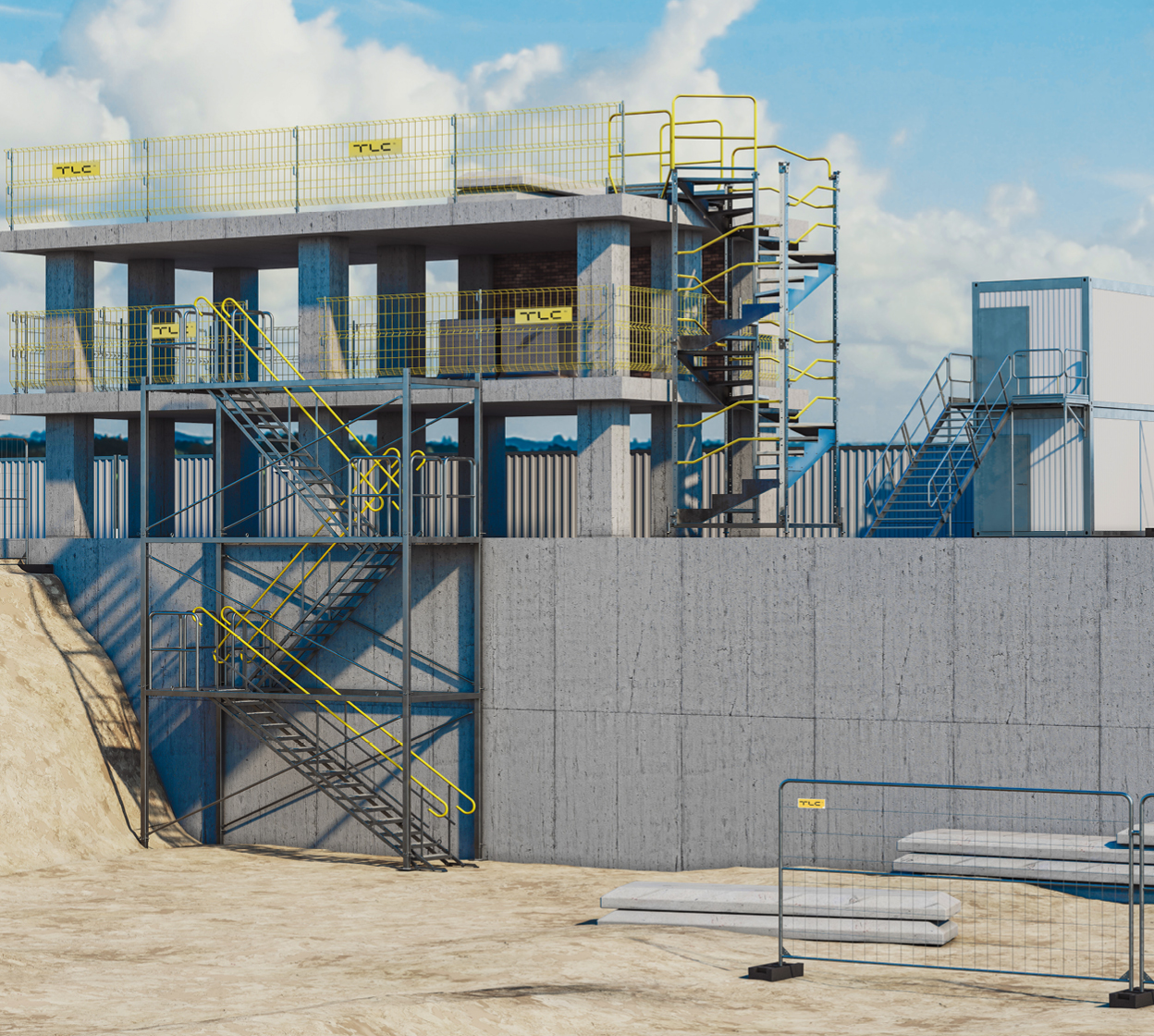

External spiral staircase and service platforms for industrial tanks