From design to installation – comprehensive support for demanding industrial projects

Read our other news

TLC EU named a Forbes Diamonds 2026 laureate – another consecutive year among the fastest-growing companies

2025 at TLC – a year in review

stairs, staircases, platforms, railings and ladders

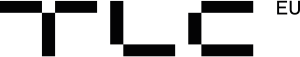

Staircases, spiral and helicoidal stars, external access platforms for tanks

Straight and spiral stairs, staircases

Internal access platforms are designed to provide safe and convenient access to key components

Spiral and helicoidal stairs, measure house for chimneys

Carla and Linea modular stairs

temporary stairs, platforms, fences and barriers

Steel, aluminum stairs and staircases for containers, terraces and accessories.

Mesh and hoarding fences, barriers and accessories.

Temporary steel and aluminum stairs (TAS), temporary steel staircases (TAS), temporary steel spiral stairs (SST).

TLC EU named a Forbes Diamonds 2026 laureate – another consecutive year among the fastest-growing companies

From design to installation – comprehensive support for demanding industrial projects

2025 at TLC – a year in review

Another season of Młode Smoki behind us – TLC supports the development of young athletes

Walkway systems for industry

stairs, staircases, platforms, railings and ladders

Construction sites protection

temporary stairs, platforms, fences and barriers

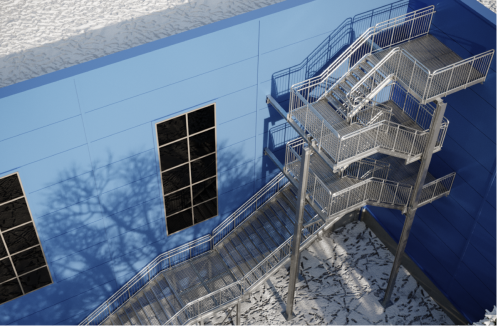

In the execution of industrial investments, the greatest challenge is ensuring consistency between design, production, and installation. One of the key challenges in these projects is the division of responsibility: one supplier is responsible for the design, another for production, and yet another for installation. Such a model leads to construction errors, the need for corrections, and delays in the schedule, resulting in additional costs and risks associated with project execution.

TLC eliminates these problems by offering comprehensive solutions – from design, through production, to installation – all within one company. With this approach, the entire process becomes more predictable and consistent, which minimizes the risk of delays, execution errors, and installation errors.

The solution to common problems related to delays and execution errors is a comprehensive approach that includes design, production, and installation within one company. This ensures full control over every stage of project execution, minimizing the risk of delays and errors. The design process is carried out in close cooperation with the production team, ensuring precise fabrication of elements ready for quick installation. The use of a modern machine park allows the production of high-precision components, and the modular prefabrication system enables fast installation, which shortens the execution time and reduces labor costs.

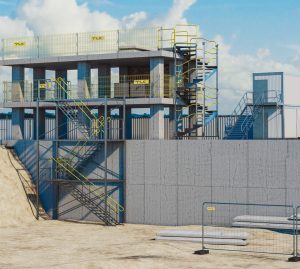

One example of the comprehensive approach applied by TLC in industrial projects was the delivery of a steel technical access staircase for a modern industrial facility in Nowy Modlin, Poland. The project included the design, production, and installation of stairs with a height of 39 meters and a weight of over 39 tons.

The completed structure was designed in accordance with Eurocodes, the PN-EN ISO 14122 series, and national regulations, ensuring its quality and safety.

Executing the entire project by TLC made it possible to avoid the risk of delays and errors associated with dividing responsibility among multiple contractors. An integrated approach – from design, through production, to installation – ensured full control over the process and eliminated typical issues related to coordinating several companies. As a result, the entire process proceeded according to schedule, saving time and reducing execution costs.

Executing the entire project by TLC made it possible to avoid the risk of delays and errors associated with dividing responsibility among multiple contractors. An integrated approach – from design, through production, to installation – ensured full control over the process and eliminated typical issues related to coordinating several companies. As a result, the entire process proceeded according to schedule, saving time and reducing execution costs.

• Steps: welded gratings 34 × 38, DIN 51130: R10 (anti-slip)

• Balustrade: child-safe, handgrip made of circular pipe ø42.4, railposts made of circular pipe ø42.4, two followers made of circular pipe ø26.9, filling of vertical round bars ø12

• Corrosion protection: hot-dip galvanizing (acc. to ISO 1461)

• Structure: prefabricated segments with intermediate landings

• Access protection: a lockable gate was installed at the base of the staircase to secure the entrance

The project in Nowy Modlin demonstrates that a comprehensive approach to the execution of large industrial structures effectively eliminates the risk of delays, execution errors, and additional costs. The integrated design, production, and installation process at TLC ensures that the delivered solutions are safe, on time, and fully adapted to the specific requirements of large industrial and warehouse facilities.

If you would like to explore the full project description or read the complete case study with technical details, drawings, and execution insights, we invite you to visit CASE STUDY.

In large industrial projects, such as those in the petrochemical, energy, or food sectors, delays and execution errors are associated with additional costs and risks. Typical problems include the need to coordinate multiple subcontractors, which often leads to installation errors and delays. To prevent this, the solution is a comprehensive approach that combines design, production, and installation within one company.

At TLC we offer comprehensive support, including design, documentation, production, and installation. We take full responsibility for the entire process, providing our clients with reliability and a guarantee of quality. This makes the entire project more predictable, and the risk of delays and installation errors is minimized.

Our projects include access platforms, stairs, and safety barriers for the petrochemical and energy sectors. Additionally, all elements are produced in our own machine park with full quality control, including protection through hot-dip galvanizing and powder coating.

A comprehensive approach – from design to installation – is not only convenience. It is a real reduction of risks and increased safety of the entire investment.

Contact us to learn how our comprehensive solutions can improve your project.

Keep up to date with our projects and news.

We're happy to share this information with you.