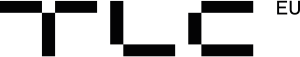

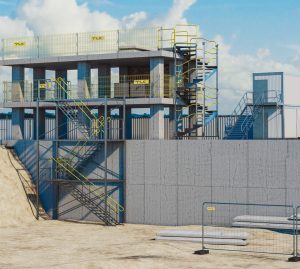

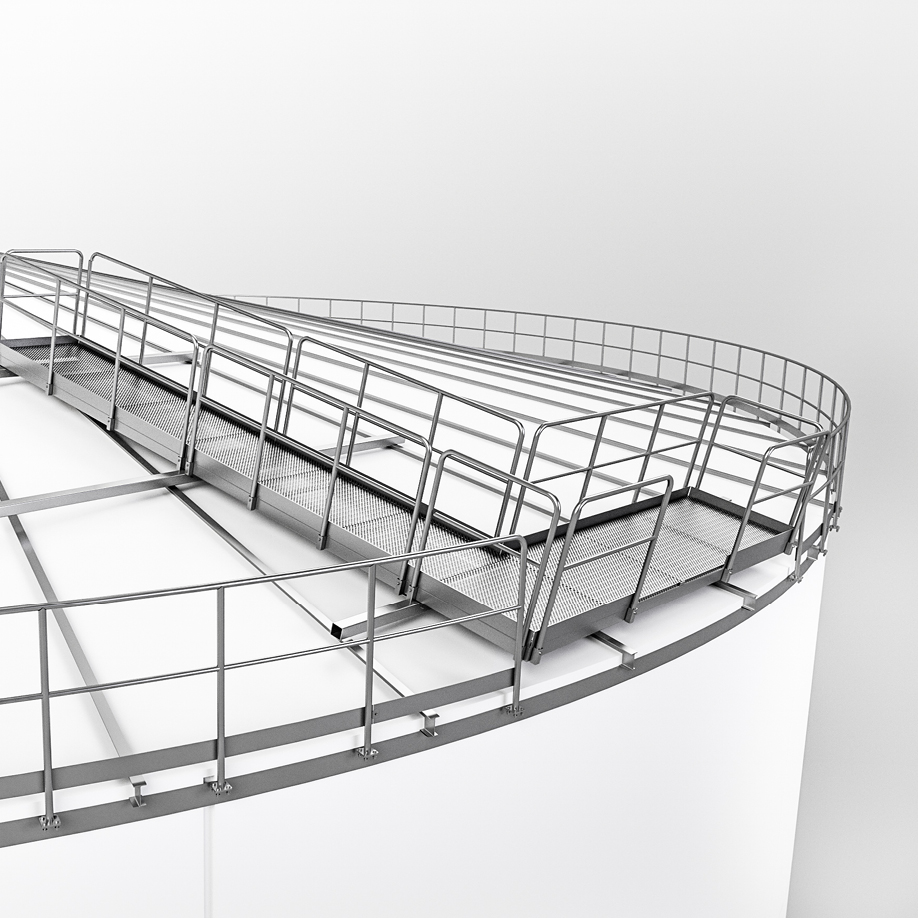

External access platforms for tanks

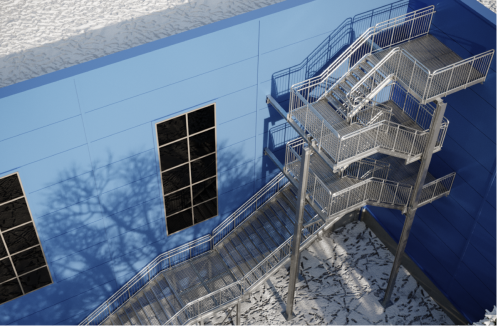

TLC provides comprehensive external access platforms for tanks, offering safe and convenient access to various levels of industrial tanks. Our systems include spiral staircases, straight staircases, technical ladders, and a variety of working platforms, allowing for efficient maintenance, inspection, and servicing of tanks. These solutions are essential for operations in sectors such as chemical, petrochemical, water treatment, and energy industries, ensuring safe working conditions at elevated heights.

- The main function of tank access platforms is to provide a walkway for servicing the tanks

- Depending on the needs (access), these platforms can be placed on, around and between the tanks

- Implementation in accordance with the documentation prepared by TLC designers or documentation provided by the Client

- Consultation of regulations and standards, as well as professional assembly services

- The additional equipment depends on usage conditions, including railings, steel stairs, technical ladders, and others

Key features

- Custom design to client needs

Each project carried out by TLC is fully adapted to the specific needs of the client. We offer flexibility in design, which means our walkway systems can be tailored to different types of tanks, ranging from small, compact units to large, high-capacity storage containers. - High corrosion resistance

Our systems are built from materials that resist atmospheric and chemical factors. Depending on the specific installation, we offer structures made of galvanized steel, ensuring long service life even in harsh environments. Additionally, anti-corrosion coatings can be applied for extra protection against external elements. - Compliance with safetystandards

All our walkway systems are designed in accordance with international standards, such as PN ISO 14122. This means that our solutions meet strict safety requirements, ensuring stable and secure access to tanks at various heights. - Advanced safety solutions

Our staircases and platforms are equipped with numerous safety features, such as handrails, protective cages, anti-slip steps, and safety barriers. These solutions are essential, especially in industries where access to tanks occurs at significant heights or in challenging operational conditions.

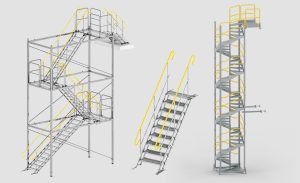

Stairs solutions for tanks

TLC offers comprehensive stair solutions for industrial tanks, combining safety and high functionality.

- Tank staircases provide secure access to rooftops, equipped with dual-side safety railings and anti-slip steps. Made from durable steel, they are hot-dip galvanized and coated to resist harsh weather conditions, meeting building regulations.

- Spiral stairs are a space-efficient option that ensures safe access to tank rooftops, featuring safety railings and anti-slip steps to enhance safety.

- Helicoidal stairs are designed for technical inspections of tanks and access to control instruments. Engineered from robust materials and adhering to strict safety standards, they ensure reliability and longevity in demanding industrial environments. With years of experience, TLC guarantees top-quality, precision, and innovative solutions in every stair project.

Technical ladders

Technical ladders, bolted or welded, are used to ensure easy movement between levels of plants, halls or industrial, storage and commercial buildings. Our metal technical ladders are not only safe but also extremely durable.

Our metal technical ladders can be used on both industrial buildings and various technical constructions thanks to a TLC developed system of fixers and construction solutions.

- Lightweight and modular construction

- Easy assembly

- Easy attaching to walls and constructions

- Comfortable rungs intervals and ladder width

- Protective cage

- Use of stainless steel or galvanized steel

- Anti-slip rungs

Steel platforms

Steel platforms are one of the key elements of access system. They also determine either the beginning of a staircase flight or its end, or are used to connect two points. When it comes to multi-storey buildings, platforms separate metal stair flights between levels.

Steel platforms are generally used to provide free and safe access to rooms or storeys.

- Traffic possible in several directions

- Give possibility to change stairs direction

- Increase the strength of stairs

- Possibility to install different fillings

TLC design and estimate departments

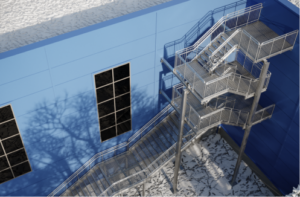

With our in-house design department, we can create custom designs tailored to various types of large tanks.

Our research and development team is continuously enhancing existing solutions and developing new innovations. TLC is also proficient in designing and manufacturing spiral stairs, arched stairs, and hybrid structures. The design team focuses on reducing the need for external brackets, buildings, or additional support systems.

The estimate department ensures prompt responses to client inquiries, delivering accurate project cost estimates and timelines. By considering crucial factors like materials, they help clients make informed decisions. With their expertise, clients receive comprehensive and reliable project evaluations, allowing for efficient planning. The close collaboration between departments ensures seamless execution and customer satisfaction, from the initial quotation to final project delivery.

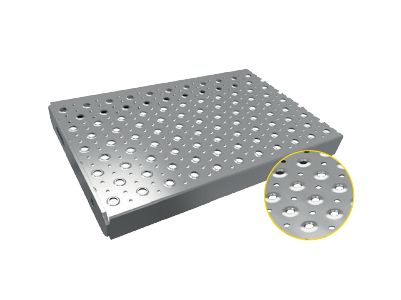

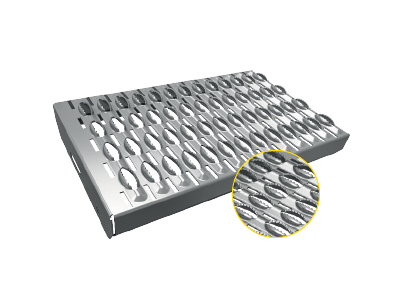

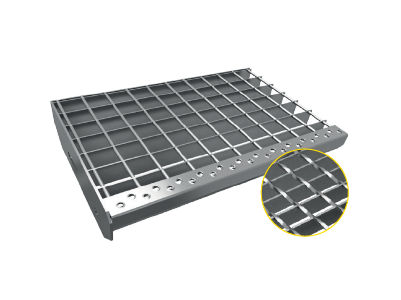

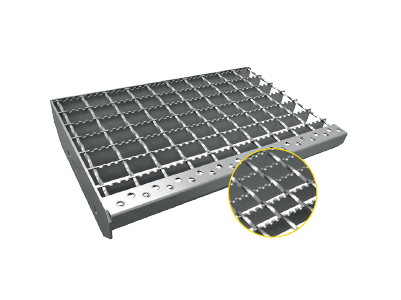

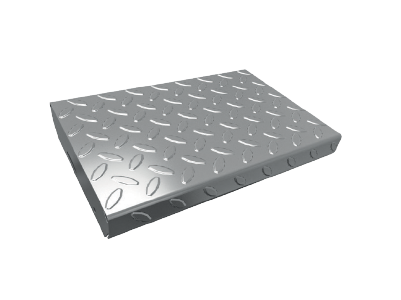

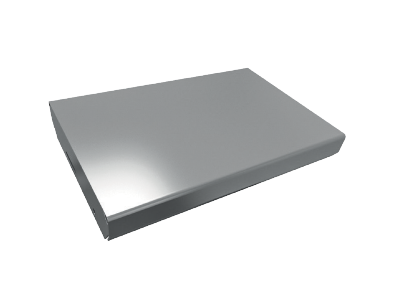

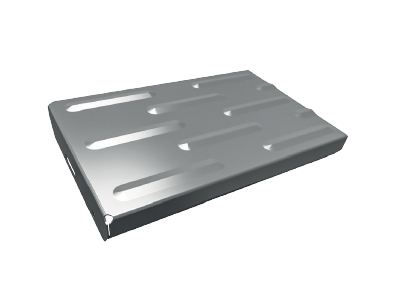

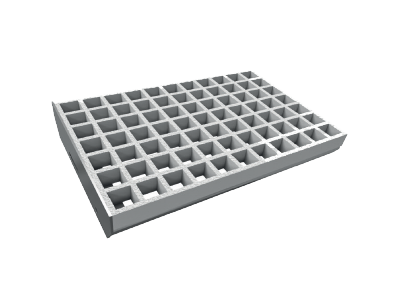

Available types of step filling

- Hot dip galvanized

- Slip resistance DIN 51130: R12

- Hot dip galvanized

- Slip resistance DIN 51130: R12

- Mesh 34 x 38

- Hot dip galvanized

- Slip resistance DIN 51130: R10

- Mesh 34 x 38

- Hot dip galvanized

- Slip resistance DIN 51130: R11

- Hot dip galvanized

- Slip resistance DIN 51130: R10

- Hot dip galvanized

- Powder painted

- Slip resistance DIN 51130: R9

- Hot dip galvanized

- Slip resistance DIN 51130: R9

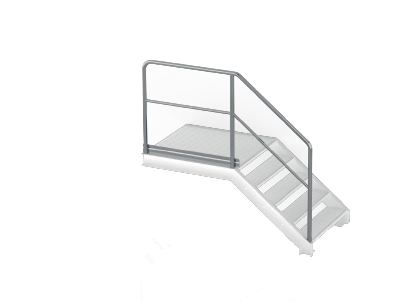

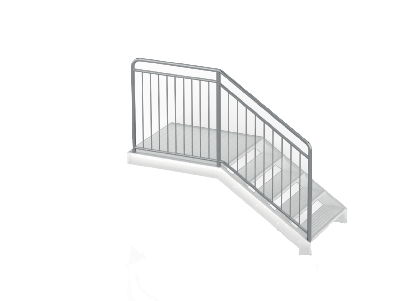

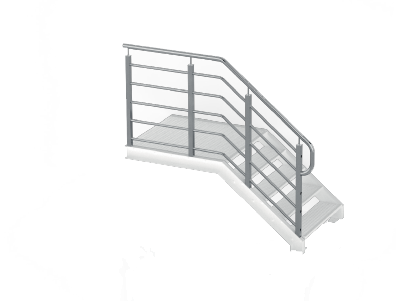

Available balustrade types

- Handgrip and railposts made of circular pipe ø42,4

- Middle bar made of circular pipe ø26,9

- Equipped with kickplate – 100 or 150 high, #1,5 or #2 thickness depending on width of railing

- Handgrip made of circular pipe ø42,4

- Railposts made of circular pipe ø42,4

- Two followers made of circular pipe ø26,9

- Filling of vertical round bars ø12

- Handgrip made of circular pipe ø48,3

- Railposts made of square profile 50x50

- Filling of horizontal circular pipe ø25

Marketing materials

General conditions of sale and installation

Certification

We ensure that all of our products are of the highest quality through compliance with Factory Manufacture Control certification with EN 1090-1:2009+A1:2011, issued by the TÜV SÜD Polska Sp. z o.o. Certification Centre.

We are a manufacturer with a certificate of the Integrated Quality, Environment and Health and Safety Management System according to ISO 9001/ ISO 14001/ ISO 45001 issued by Bureau Veritas Certification.

Our construction products meet the requirements of the European Directive 305/2011 (CPR) for structural steel and aluminum.

We have Environmental Product Declarations (EPDs) for our products. This is a global Type III declaration programme that follows the principles of ISO 14025. An EPD is a standardised document that provides information on the environmental impact of a product.

Integrated Management System Policy

Gorlice, 1.05.2023, 5th edition

Design, production of metal structures, powder coating, hot-dip galvanzing of steel structures

Bureau Veritas Certification, ISO 9001:2015; ISO 14001:2015; ISO 45001:2018

EPD Environmental Product Declaration

In accordance with ISO 14025:2006 and EN 15804:2012+A2:2019/AC:2021 for: STEEL STAIRS Steel straight/spiral stairs, container stairs P-SK3, 4, 5, 6, 7, 8, SK-KS, TAS and SST temporary stairs, ASTA, CARLA, LINEA modular stairs, industrial communication systems including ladders