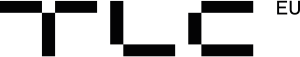

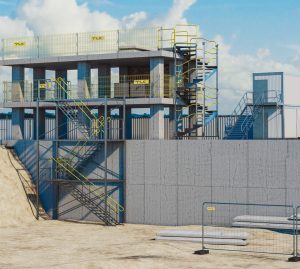

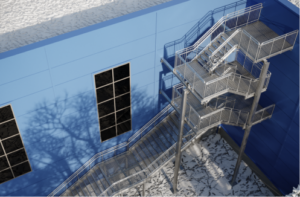

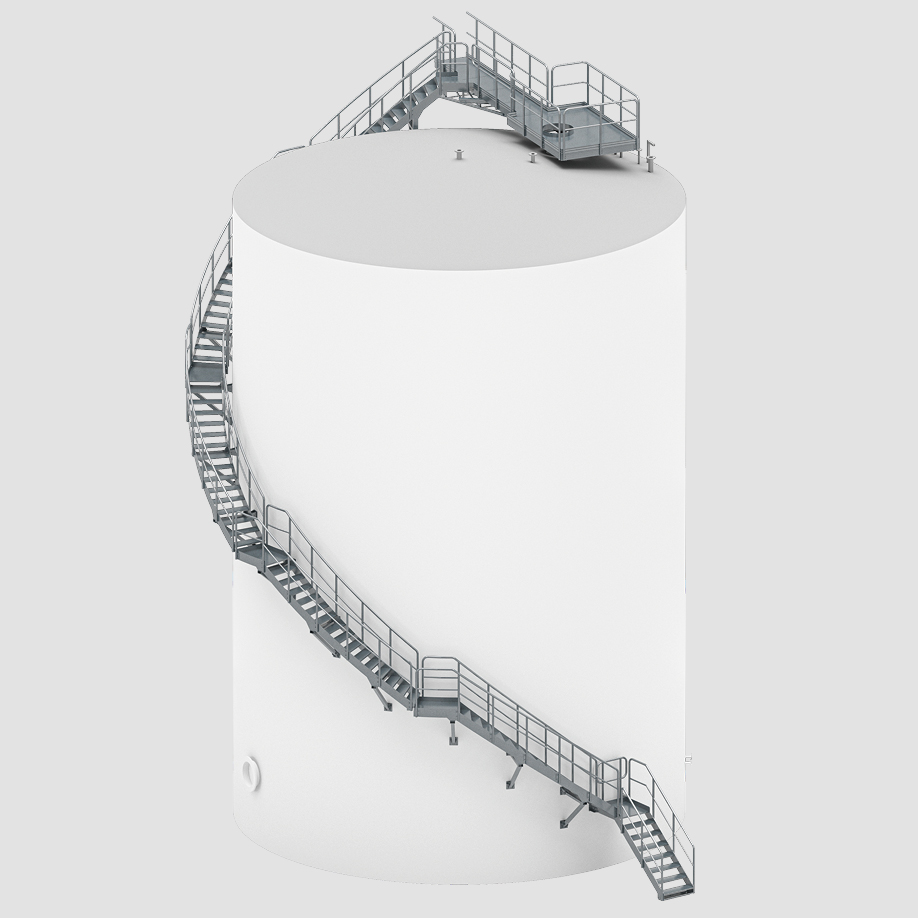

Helicoidal stairs for tanks

TLC tank staircases are specially designed to provide safe and reliable access to industrial tanks of various sizes. They are essential in facilitating maintenance, inspection, and service work for tanks used in different industries such as petrochemicals, food processing, water treatment, and energy. Built with durability and safety in mind, these stairs meet the highest industrial standards and can be customized to the specific requirements of each installation.

Usage

TLC’s helicoidal staircases are suitable for various types of tanks, including:

- Bioenergy tanks: Providing safe and efficient access to bioenergy storage and processing tanks for routine inspections and maintenance of equipment.

- Storage tanks: For large storage tanks, the spiral design allows operators to easily access different levels of the tank while minimizing the footprint of the staircase.

- Chemical and petrochemical tanks: Ensuring compliance with strict safety standards, our staircases provide access to tanks storing hazardous chemicals or petrochemicals.

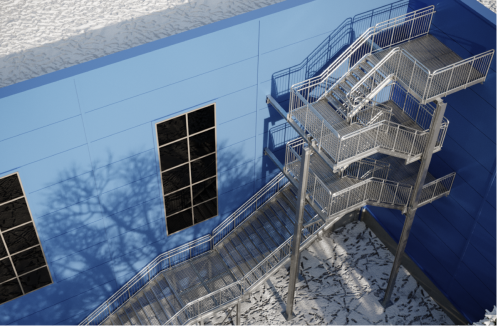

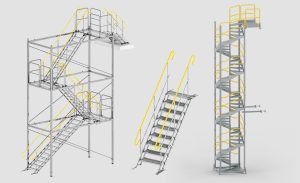

Advantages of helicoidal Stairs

- Space-efficient design

One of the most significant advantages of helicoidal staircases is their space-saving design. The spiral configuration allows them to wrap around the exterior of the tank, requiring far less ground space compared to traditional straight staircases. This is particularly beneficial for facilities where every square meter of space counts. - Enhanced accessibility

Helicoidal stairs provide continuous, easy access to various levels of the tank. Whether for routine inspections or emergency access, these stairs allow personnel to reach control and measuring instruments without the need for ladders or scaffolding. This is crucial for tanks where frequent access to upper levels is required. - Low maintenance

Helicoidal staircases from TLC are built to last with minimal maintenance required. The materials used are resistant to corrosion, wear, and environmental stressors, ensuring that the staircases retain their structural integrity and safety features over time. This reduces the need for frequent repairs or replacements, saving both time and operational costs for your facility.

Safety Features

At TLC, safety is our top priority. Our helicoidal staircases are equipped with a range of safety features, including:

- Non-slip steps to prevent accidents in wet or hazardous conditions.

- Sturdy handrails designed to provide secure support at all heights.

- Compliance with international safety standards such as PN ISO 14122, ensuring that our staircases meet the highest safety requirements in industrial settings.

TLC design and estimate departments

Our Research and Development team continuously works on enhancing current solutions and developing new ones. TLC also specializes in designing and manufacturing stairs, and steel structures. Our design team emphasizes reducing the need for external brackets, buildings, or additional supports.

The Estimate Department provides prompt responses to client inquiries, offering accurate estimates for project costs and timelines. By considering essential factors like materials, they help clients make well-informed decisions. With their expertise, clients receive comprehensive and reliable project evaluations, allowing for efficient planning. The close collaboration between departments ensures smooth project execution and customer satisfaction from the initial estimate to the project’s completion.

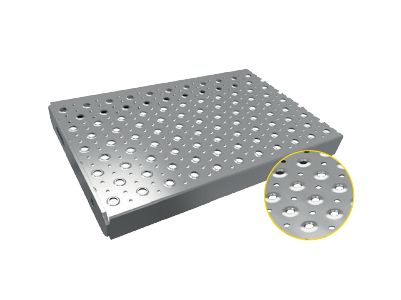

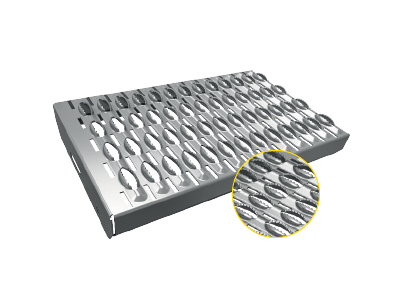

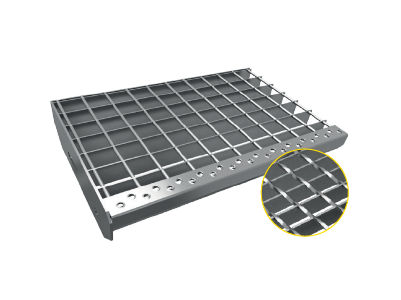

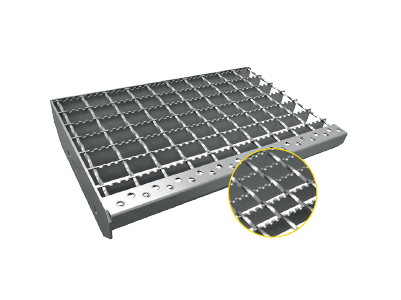

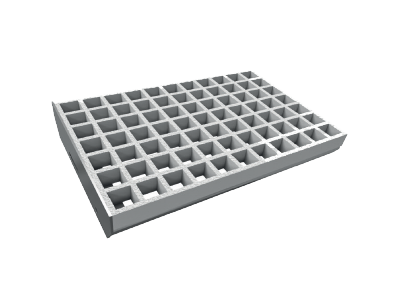

Available types of step filling

- Hot dip galvanized

- Slip resistance DIN 51130: R12

- Hot dip galvanized

- Slip resistance DIN 51130: R12

- Mesh 34 x 38

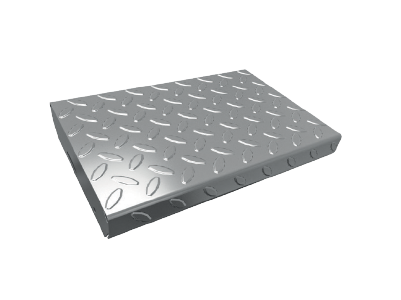

- Hot dip galvanized

- Slip resistance DIN 51130: R10

- Mesh 34 x 38

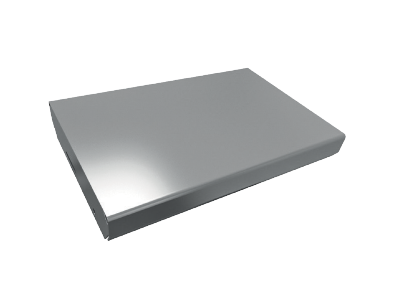

- Hot dip galvanized

- Slip resistance DIN 51130: R11

- Hot dip galvanized

- Slip resistance DIN 51130: R10

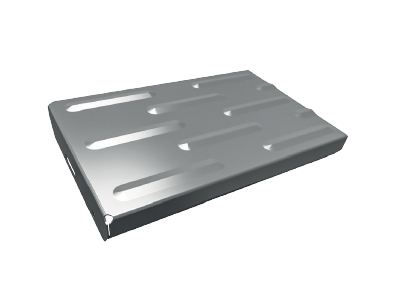

- Hot dip galvanized

- Powder painted

- Slip resistance DIN 51130: R9

- Hot dip galvanized

- Slip resistance DIN 51130: R9

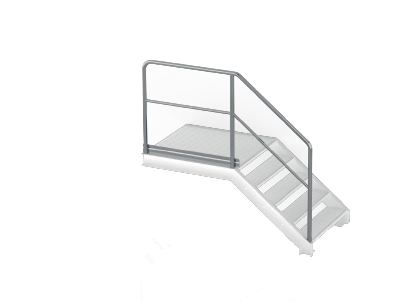

Available balustrade types

- Handgrip and railposts made of circular pipe ø42,4

- Middle bar made of circular pipe ø26,9

- Equipped with kickplate – 100 or 150 high, #1,5 or #2 thickness depending on width of railing

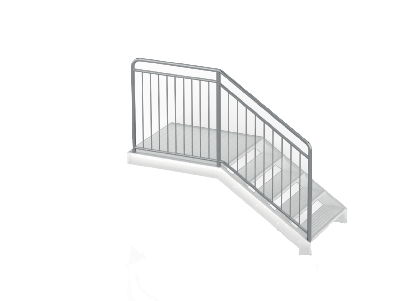

- Handgrip made of circular pipe ø42,4

- Railposts made of circular pipe ø42,4

- Two followers made of circular pipe ø26,9

- Filling of vertical round bars ø12

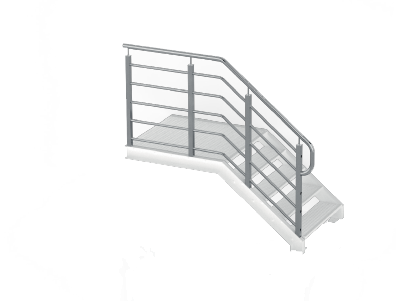

- Handgrip made of circular pipe ø48,3

- Railposts made of square profile 50x50

- Filling of horizontal circular pipe ø25

Marketing materials

General conditions of sale and installation

Certification

We ensure that all of our products are of the highest quality through compliance with Factory Manufacture Control certification with EN 1090-1:2009+A1:2011, issued by the TÜV SÜD Polska Sp. z o.o. Certification Centre.

We are a manufacturer with a certificate of the Integrated Quality, Environment and Health and Safety Management System according to ISO 9001/ ISO 14001/ ISO 45001 issued by Bureau Veritas Certification.

Our construction products meet the requirements of the European Directive 305/2011 (CPR) for structural steel and aluminum.

We have Environmental Product Declarations (EPDs) for our products. This is a global Type III declaration programme that follows the principles of ISO 14025. An EPD is a standardised document that provides information on the environmental impact of a product.

Integrated Management System Policy

Gorlice, 1.05.2023, 5th edition

Design, production of metal structures, powder coating, hot-dip galvanzing of steel structures

Bureau Veritas Certification, ISO 9001:2015; ISO 14001:2015; ISO 45001:2018

EPD Environmental Product Declaration

In accordance with ISO 14025:2006 and EN 15804:2012+A2:2019/AC:2021 for: STEEL STAIRS Steel straight/spiral stairs, container stairs P-SK3, 4, 5, 6, 7, 8, SK-KS, TAS and SST temporary stairs, ASTA, CARLA, LINEA modular stairs, industrial communication systems including ladders