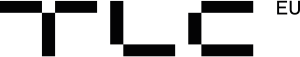

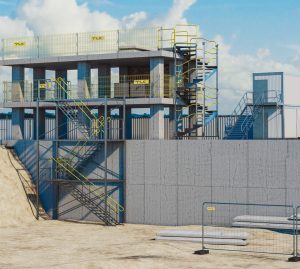

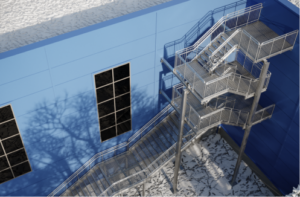

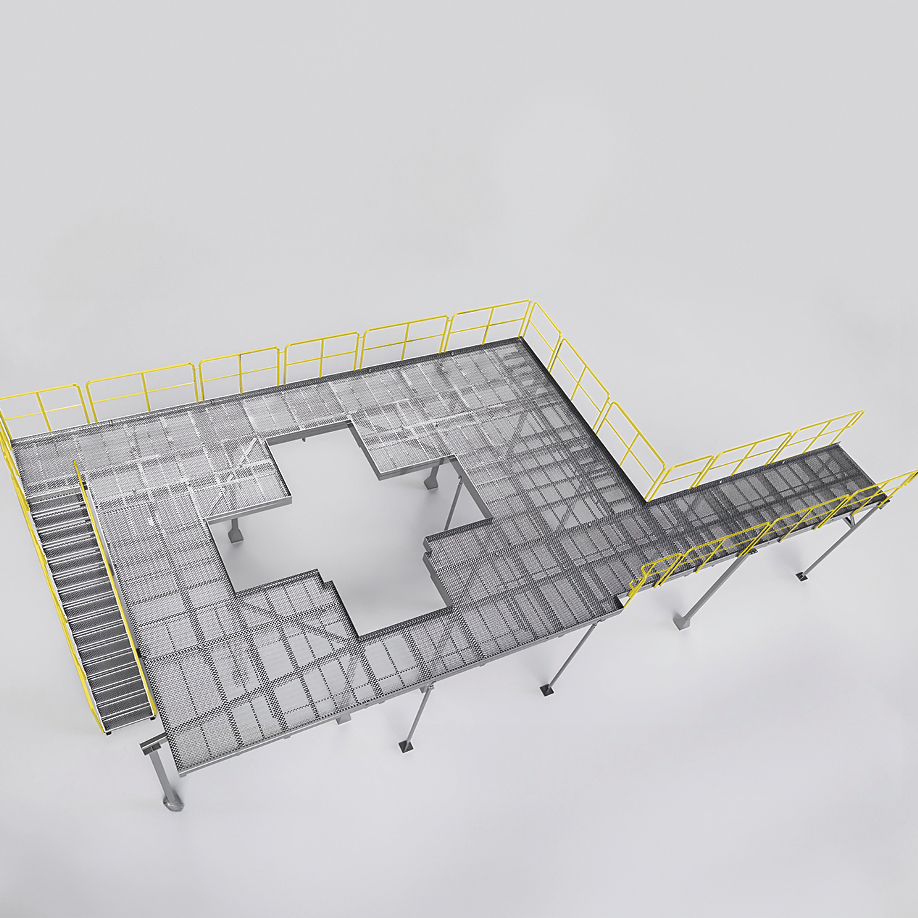

Internal access platforms to machine parks

TLC internal access platforms are designed to provide safe and convenient access to key components of process lines across various industries. They are used for the servicing, maintenance, and repair of production equipment, ensuring ergonomic and safe working conditions for personnel.

Our platforms are made from high-quality materials, ensuring durability and corrosion resistance. Thanks to their flexible construction, the platforms can be tailored to the specific needs of any facility, providing access to hard-to-reach areas in processing lines.

Usage

- Manufacturing industry

Service platforms allow for easy access to hard-to-reach parts of machinery, which is crucial for regular maintenance, servicing, and repairs. They also ensure safety for workers operating at heights. - Assembly plants

In assembly plants where complex systems are located on different levels, platforms provide ergonomic access, enhancing workflow efficiency. They can be installed around assembly lines to offer optimal access to all key areas. - Warehouses and logistics

In warehouses and distribution centers, service platforms can be used to optimize workspace, allowing access to higher sections of shelving and technological equipment. - Energy and petrochemical industry

In sectors with tall and complex installations, service platforms are essential for regular inspections and maintenance of components such as tanks, pipelines, and process lines. - Food and pharmaceutical industry

Service platforms are used in facilities where access to multi-level processing equipment is required, especially where strict hygiene and safety regulations are enforced.

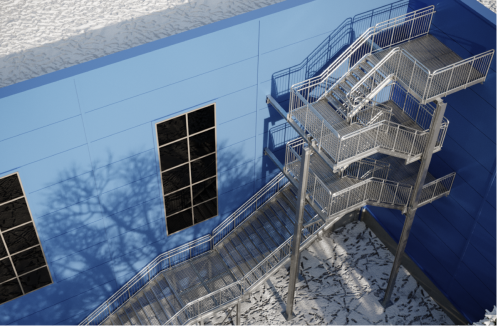

Internal access platforms to machine parks and assembly lines are a platform or a set of platforms that can be in a multi-storey system, designed to:

- Ensure maximum use of working surface,

- Support the technological line,

- Ensure appropriate and safe access to higher parts of machines,

- Optimize and improve the production process.

The use of internal platforms makes it possible to increase the operational volume inside the hall without interfering with the building cubature and without incurring the costs associated with its expansion. The platform filling has durable anti-slip properties to maximize user protection. The additional equipment depends on the operating conditions. It includes: steel railings, stairs, technical ladders, and others.

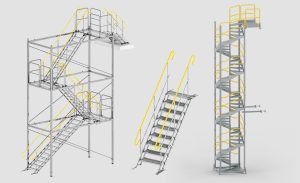

Advantages of TLC maintenance platforms

- Durable construction: Made from galvanized steel or aluminum, our platforms are weather-resistant and corrosion-proof.

- Workplace safety: Platforms are equipped with safety railings and non-slip surfaces, enhancing user safety.

- Customization options: The platforms can be customized in size and design to meet the specific requirements of any industrial installation.

- Easy assembly and disassembly: The modular design allows for quick assembly and disassembly, minimizing downtime in production.

TLC maintenance platforms are a reliable solution for companies seeking safe and ergonomic access to equipment in process lines.

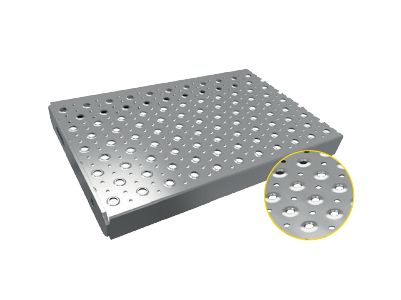

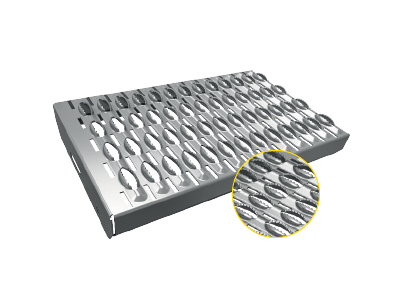

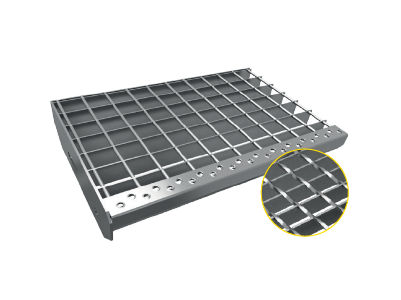

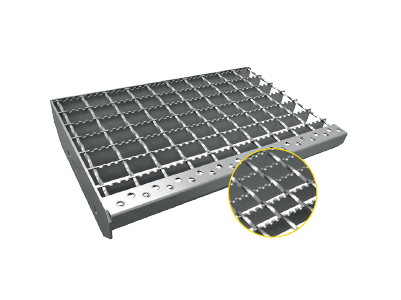

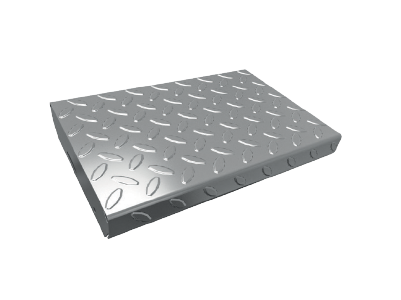

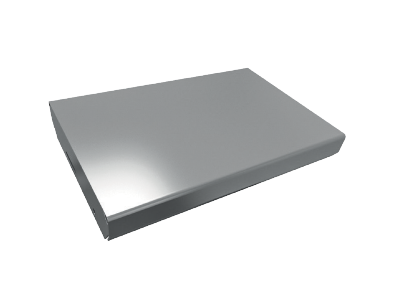

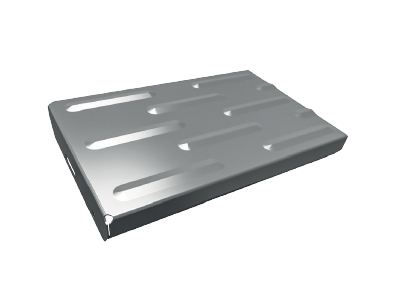

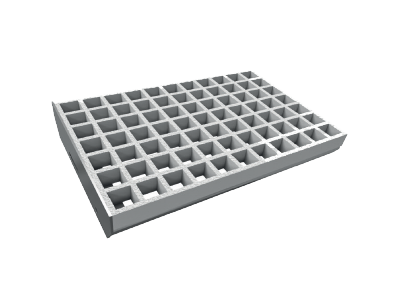

Available types of step filling

- Hot dip galvanized

- Slip resistance DIN 51130: R12

- Hot dip galvanized

- Slip resistance DIN 51130: R12

- Mesh 34 x 38

- Hot dip galvanized

- Slip resistance DIN 51130: R10

- Mesh 34 x 38

- Hot dip galvanized

- Slip resistance DIN 51130: R11

- Hot dip galvanized

- Slip resistance DIN 51130: R10

- Hot dip galvanized

- Powder painted

- Slip resistance DIN 51130: R9

- Hot dip galvanized

- Slip resistance DIN 51130: R9

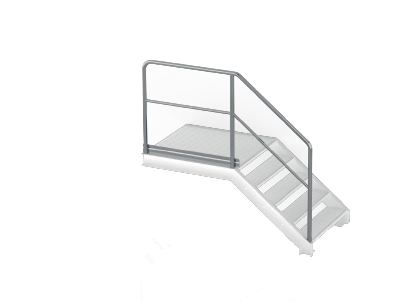

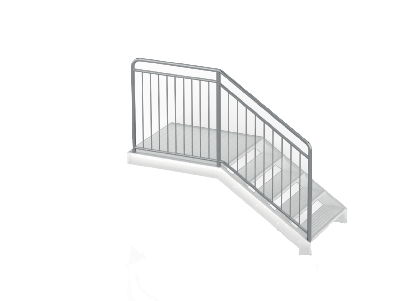

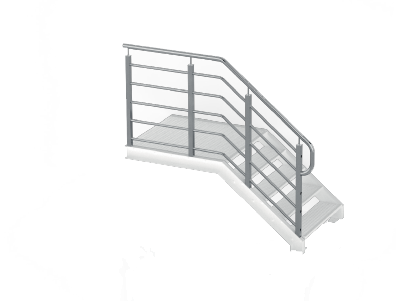

Available balustrade types

- Handgrip and railposts made of circular pipe ø42,4

- Middle bar made of circular pipe ø26,9

- Equipped with kickplate – 100 or 150 high, #1,5 or #2 thickness depending on width of railing

- Handgrip made of circular pipe ø42,4

- Railposts made of circular pipe ø42,4

- Two followers made of circular pipe ø26,9

- Filling of vertical round bars ø12

- Handgrip made of circular pipe ø48,3

- Railposts made of square profile 50x50

- Filling of horizontal circular pipe ø25

Marketing materials

General conditions of sale and installation

Certification

We ensure that all of our products are of the highest quality through compliance with Factory Manufacture Control certification with EN 1090-1:2009+A1:2011, issued by the TÜV SÜD Polska Sp. z o.o. Certification Centre.

We are a manufacturer with a certificate of the Integrated Quality, Environment and Health and Safety Management System according to ISO 9001/ ISO 14001/ ISO 45001 issued by Bureau Veritas Certification.

Our construction products meet the requirements of the European Directive 305/2011 (CPR) for structural steel and aluminum.

We have Environmental Product Declarations (EPDs) for our products. This is a global Type III declaration programme that follows the principles of ISO 14025. An EPD is a standardised document that provides information on the environmental impact of a product.

Integrated Management System Policy

Gorlice, 1.05.2023, 5th edition

Design, production of metal structures, powder coating, hot-dip galvanzing of steel structures

Bureau Veritas Certification, ISO 9001:2015; ISO 14001:2015; ISO 45001:2018

EPD Environmental Product Declaration

In accordance with ISO 14025:2006 and EN 15804:2012+A2:2019/AC:2021 for: STEEL STAIRS Steel straight/spiral stairs, container stairs P-SK3, 4, 5, 6, 7, 8, SK-KS, TAS and SST temporary stairs, ASTA, CARLA, LINEA modular stairs, industrial communication systems including ladders