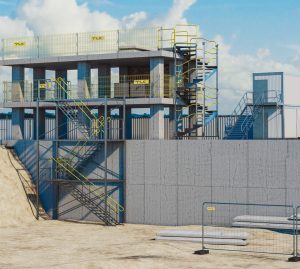

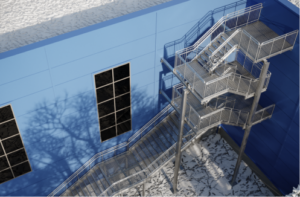

Spiral, helicoidal stairs and platforms for chimneys

Steel stairs for industrial chimneys are robust structures that provide access to different levels of a chimney. Thanks to modern solutions and the expertise of our engineers, TLC steel chimney stairs ensure safety during use. They are made from the highest quality materials and undergo appropriate corrosion protection. As an international manufacturer, we guarantee professional advice and compliance with the industrial standards of each country.

Usage

Industrial chimneys are designed for the discharge of exhaust gases, smoke, and production gases. They are used in almost all sectors of the processing industry, including:

- The mining industry

- The processing industry

- The fuel and energy sector

- The metallurgical industry

- The food industry

- The agricultural sector

Thanks to the possibility of designing stairs according to customer specifications, TLC steel stairs can be easily adapted to any type of steel chimney. Communication on free-standing industrial chimneys is crucial for their functionality.

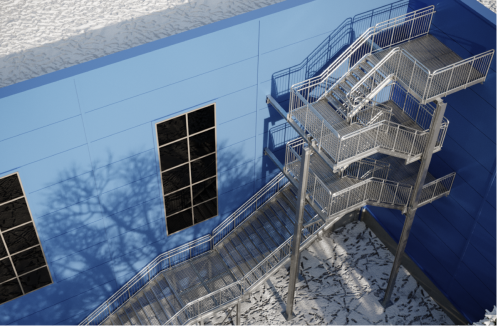

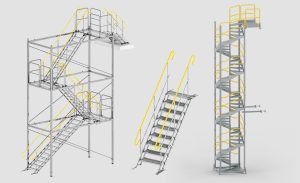

Types of chimney stairs

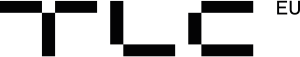

Spiral stairs for chimneys – these stairs have a curved design and are often referred to as fan stairs. They serve as an access route around industrial chimneys and are designed to provide free access at various heights. The spiral staircase allows for the inspection and maintenance of the chimney.

Thanks to the possibility of designing stairs according to customer specifications, we offer different types of stairs for steel chimneys:

- Chimney stairs for waste incineration plants

- Chimney stairs for industrial chimneys

- Chimney stairs for thermal power plant chimneys

- Chimney stairs for power plant chimneys

- Chimney stairs for petrochemical installations

- Chimney stairs for the food and confectionery industry (lime kilns)

- Chimney stairs for paper mills

- Chimney stairs for coal mines

- Chimney stairs for iron and non-ferrous metal plants

Platforms and technical ladders for chimneys

Chimney platforms – these platforms are designed to provide safe and stable working areas at various heights around industrial chimneys. They serve as essential access points for inspection, maintenance, and repair tasks, ensuring safety and functionality. Chimney platforms are typically installed at key points along the chimney’s height, offering reliable support for workers and equipment.

Thanks to the ability to customize designs according to customer specifications, we offer different types of platforms for steel chimneys.

Technical ladders for chimneys – steel structures equipped with a safety cage and permanently attached to the building. For added safety, these ladders feature non-slip steps according to TLC standards.

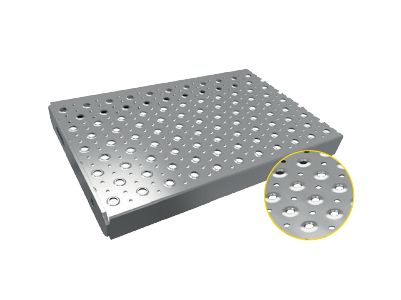

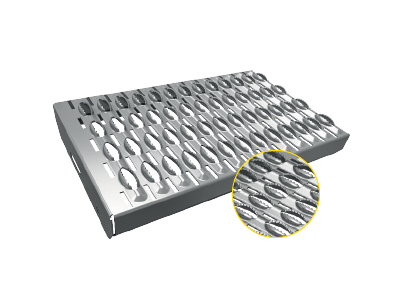

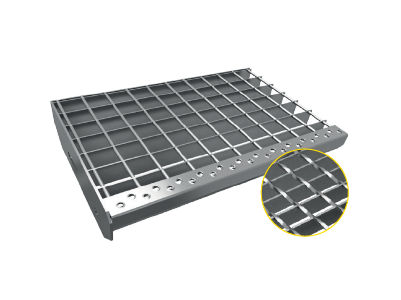

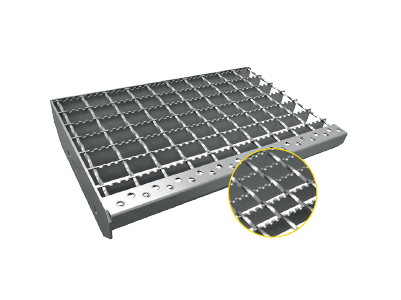

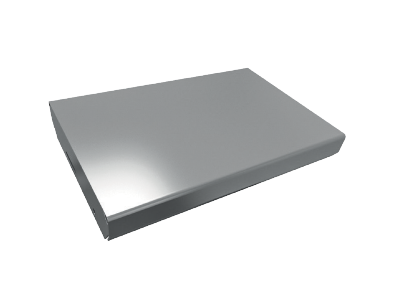

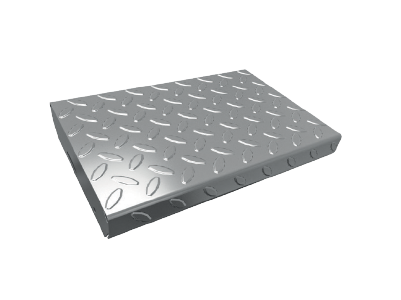

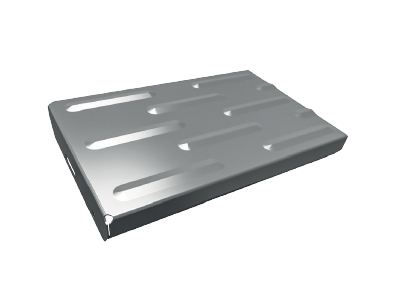

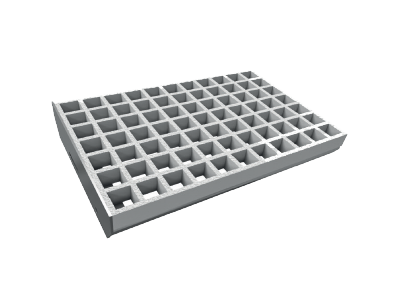

Available types of step filling

- Hot dip galvanized

- Slip resistance DIN 51130: R12

- Hot dip galvanized

- Slip resistance DIN 51130: R12

- Mesh 34 x 38

- Hot dip galvanized

- Slip resistance DIN 51130: R10

- Mesh 34 x 38

- Hot dip galvanized

- Slip resistance DIN 51130: R11

- Hot dip galvanized

- Powder painted

- Slip resistance DIN 51130: R9

- Hot dip galvanized

- Slip resistance DIN 51130: R10

- Hot dip galvanized

- Slip resistance DIN 51130: R9

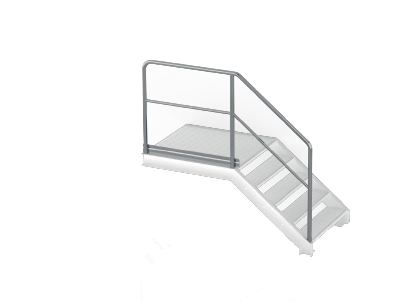

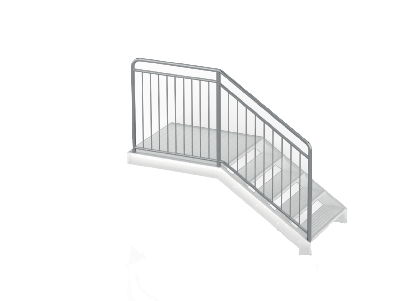

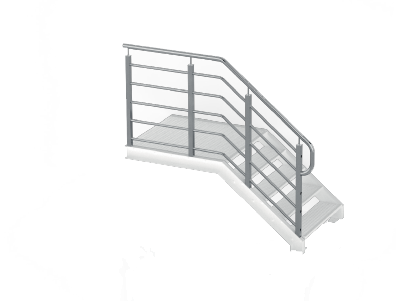

Available balustrade types

- Handgrip and railposts made of circular pipe ø42,4

- Middle bar made of circular pipe ø26,9

- Equipped with kickplate – 100 or 150 high, #1,5 or #2 thickness depending on width of railing

- Handgrip made of circular pipe ø42,4

- Railposts made of circular pipe ø42,4

- Two followers made of circular pipe ø26,9

- Filling of vertical round bars ø12

- Handgrip made of circular pipe ø48,3

- Railposts made of square profile 50x50

- Filling of horizontal circular pipe ø25

Marketing materials

General conditions of sale and installation

Certification

We ensure that all of our products are of the highest quality through compliance with Factory Manufacture Control certification with EN 1090-1:2009+A1:2011, issued by the TÜV SÜD Polska Sp. z o.o. Certification Centre.

We are a manufacturer with a certificate of the Integrated Quality, Environment and Health and Safety Management System according to ISO 9001/ ISO 14001/ ISO 45001 issued by Bureau Veritas Certification.

Our construction products meet the requirements of the European Directive 305/2011 (CPR) for structural steel and aluminum.

We have Environmental Product Declarations (EPDs) for our products. This is a global Type III declaration programme that follows the principles of ISO 14025. An EPD is a standardised document that provides information on the environmental impact of a product.

Integrated Management System Policy

Gorlice, 1.05.2023, 5th edition

Design, production of metal structures, powder coating, hot-dip galvanzing of steel structures

Bureau Veritas Certification, ISO 9001:2015; ISO 14001:2015; ISO 45001:2018

EPD Environmental Product Declaration

In accordance with ISO 14025:2006 and EN 15804:2012+A2:2019/AC:2021 for: STEEL STAIRS Steel straight/spiral stairs, container stairs P-SK3, 4, 5, 6, 7, 8, SK-KS, TAS and SST temporary stairs, ASTA, CARLA, LINEA modular stairs, industrial communication systems including ladders