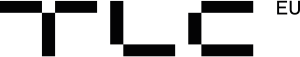

Spiral stairs

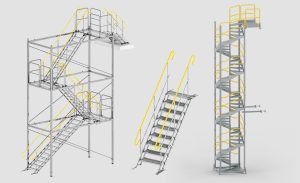

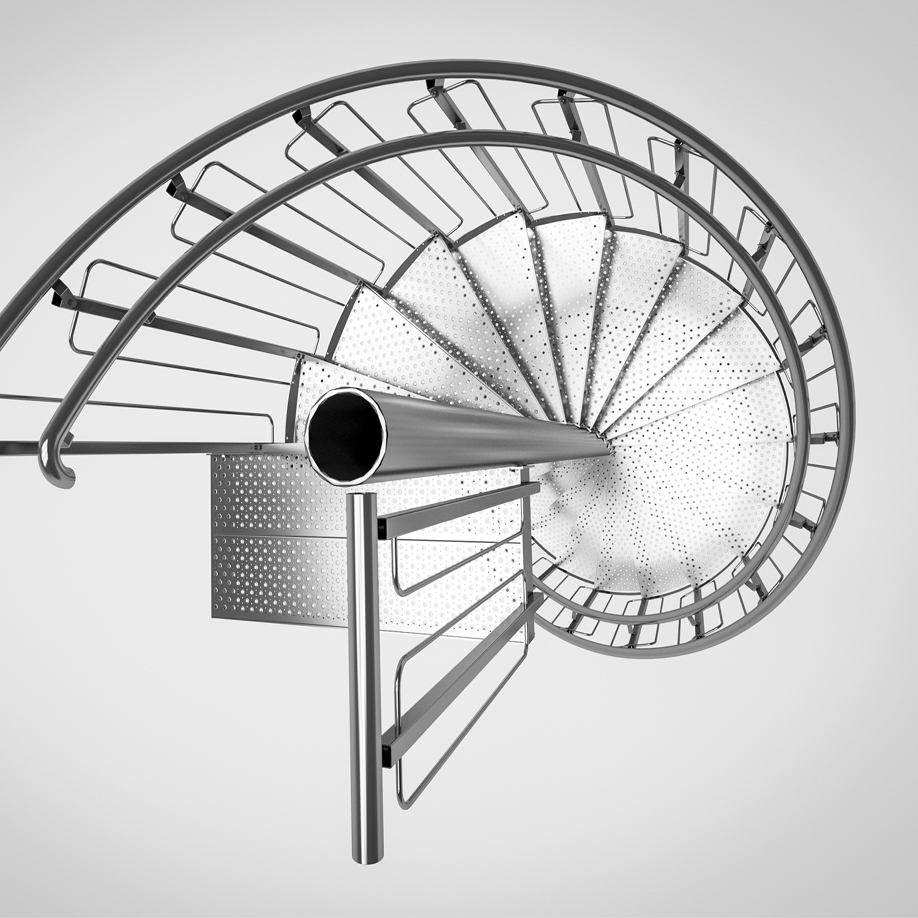

TLC spiral staircases are characterized by their light weight, allowing for easy and quick assembly. They are an alternative to traditional straight steel staircases. Steel spiral staircases are used across all industries. They are an ideal solution for spaces with limited room – due to their compact design, which rotates around a central column, they ensure optimal use of available space.

Metal spiral stairs are available in two versions:

- with a central column on hangers

- with a central pole (bushing stairs)

The spiral staircase is safe for daily use, primarily due to the presence of a handrail – an inner handrail on the central post and an additional handrail on the balustrade, which are always “in front” of the user when descending the stairs, minimizing the risk of falling. Another important factor is the use of steps with high slip resistance.

Usage

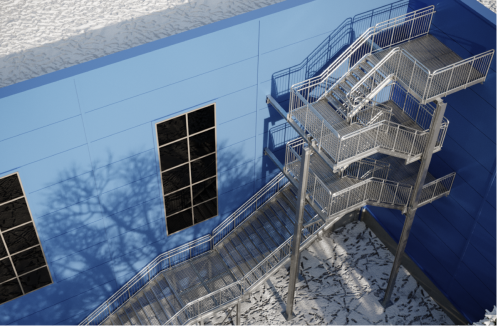

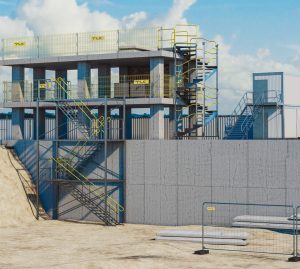

Spiral staircases are used:

- in production halls,

- in warehouses,

- as roof access to large tanks,

- as part of the walkway system

- in industrial facilities

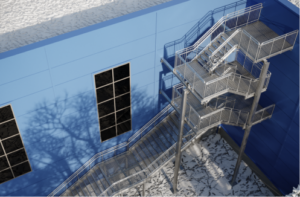

Spiral staircases offer versatility and are adaptable for both indoor and outdoor applications, making them a practical solution for businesses in various industries, from construction and manufacturing to commercial real estate and public infrastructure projects.

Advantages of spiral stairs

- Light and durable

solutions regarding spiral stairs, developed by TLC, let us produce stairs that will meet the expectations of our customers. Innovative design helped us maintain durability imposed by current standards despite reducing the weight of the entire construction.

- Significant protection

Anti-corrosion protection and high durability are guaranteed by hot dip galvanization according to EN ISO 1461 (DIN 50976). Powder coating with RAL or NCS color ensure high aesthetics of the stairs.

- Well-knit construction

They will fit the areas with limited space being a perfect alternative to winder and straight constructions. - Safety first

TLC’s standards guarantee the highest protection thanks to children-safe railings and anti-slip steps. - No limits

We will design, manufacture, transport and assembly the steel spiral staircase throughout Europe. In our production process, we use standard materials to minimize lead times. However, we understand the importance of a personalized approach. That’s why we also implement non-standard solutions to meet our clients’ expectations. We offer a comprehensive service: consulting, on-site measurements, developing a custom design, manufacturing, and assembling the structure.

TLC design and estimate departments

Our design department enables us to create innovative and carefully planned production solutions, optimizing both time and cost efficiency. Our Construction and Technology team is always available to guide clients in selecting the most suitable solution for their specific needs. The Research and Development team is constantly focused on improving current solutions and creating new innovations. Our design team reduces the need for external supports, buildings, or brackets. The steps are secured using anchors, while the fillings are attached with spacer connector.

Our estimate department ensures prompt and precise responses to client inquiries, providing detailed estimates of project costs and timelines. By taking into account key factors like materials, they assist clients in making informed decisions. Thanks to their expertise, clients receive comprehensive and trustworthy project assessments, enabling efficient planning. The close collaboration between departments guarantees smooth project execution and customer satisfaction from the initial quote to project completion.

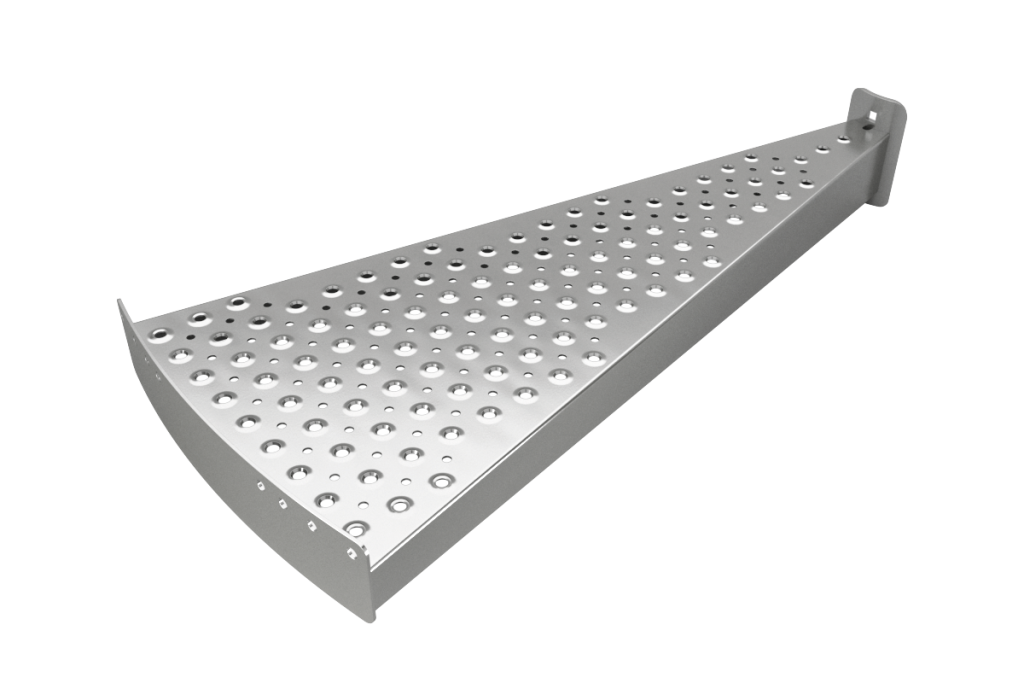

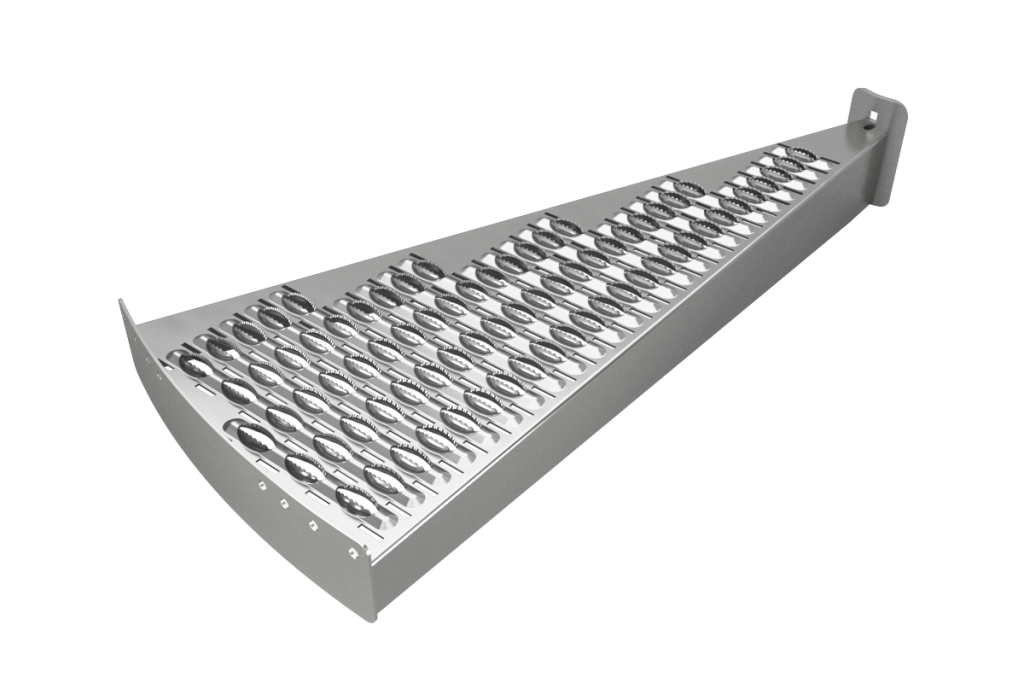

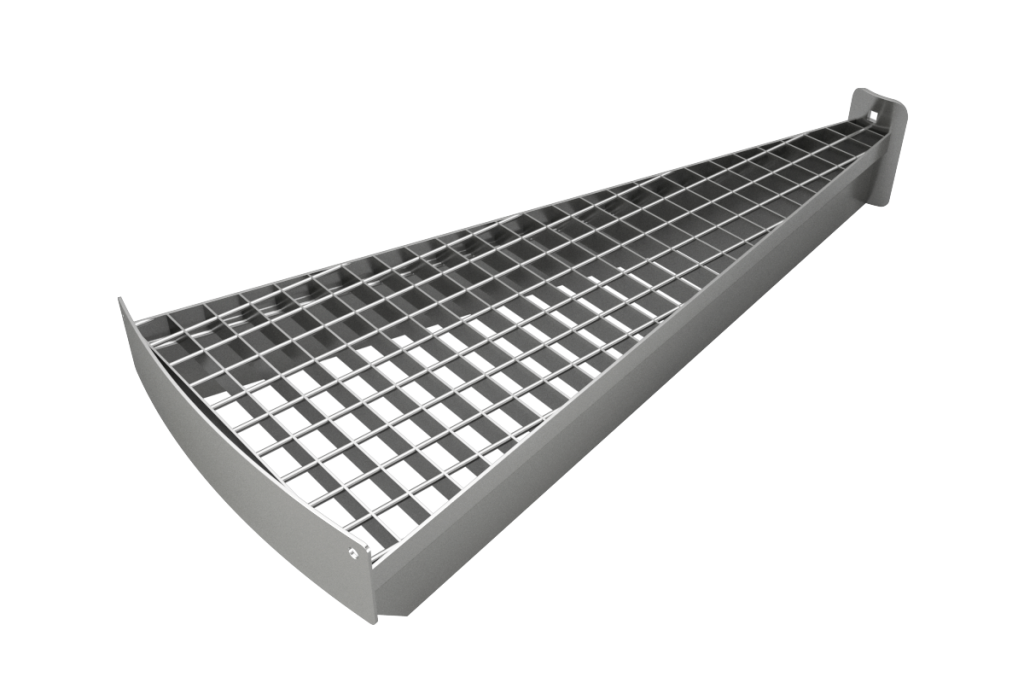

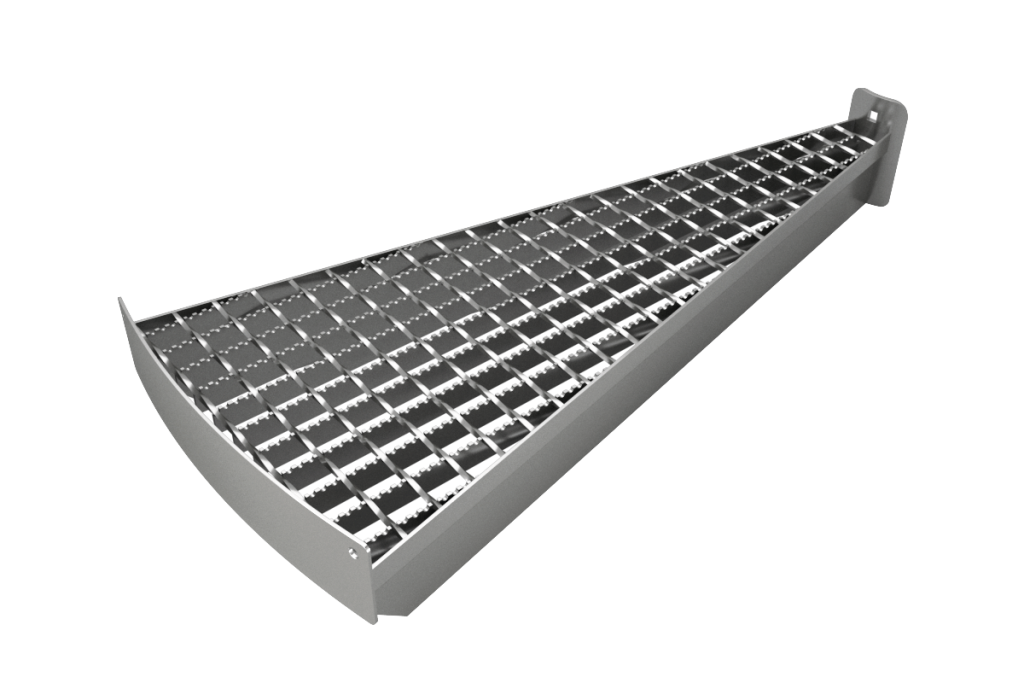

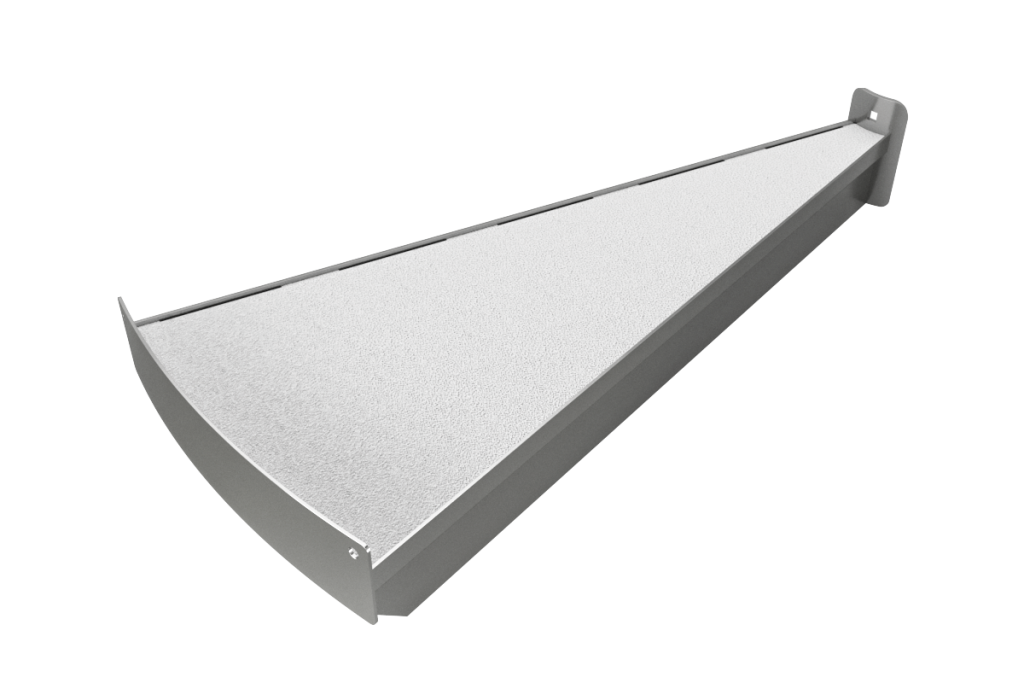

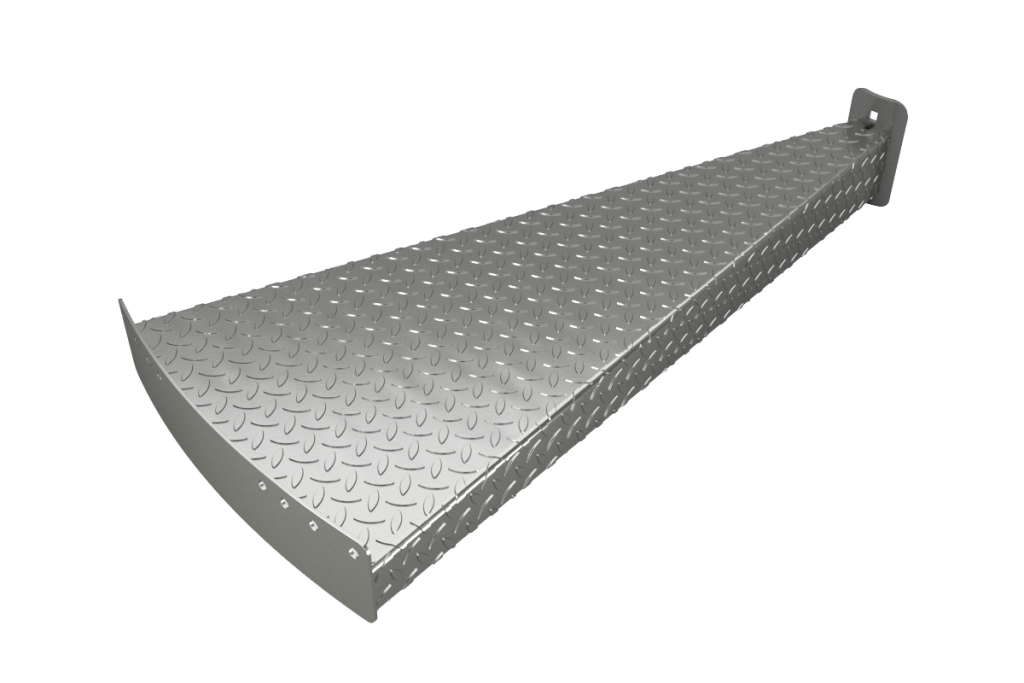

Available types of step filling

- Hot dip galvanized

- Slip resistance DIN 51330: R12

- Hot dip galvanized

- Slip resistance DIN 51130: R12

- Mesh 34 x 38

- Hot dip galvanized

- Slip resistance DIN 51130: R10

- Mesh 34 x 38

- Hot dip galvanized

- Slip resistance DIN 51130: R11

- Hot dip galvanized

- Powder painted

- Slip resistance DIN 51130: R9

- Hot dip galvanized

- Slip resistance DIN 51130: R10

Available balustrade types

- Rail posts made of square profile 30x30

- Handgrips made of pipe 42,4

- Rail posts made of square profile 30x30

- Handgrips made of pipe 42,4

- Additonal folIower fiat 40x3

- Rail posts made of square profile 30x30 + vertical round bars ø10 mm

- Handgrips made of pipe 42,4

- Rail posts made of square profile 30x30

- Handgrips made of pipe 42,4

- Filling made of 2 pipes 21,3 and vertical round bars 010

Marketing materials

General conditions of sale and installation

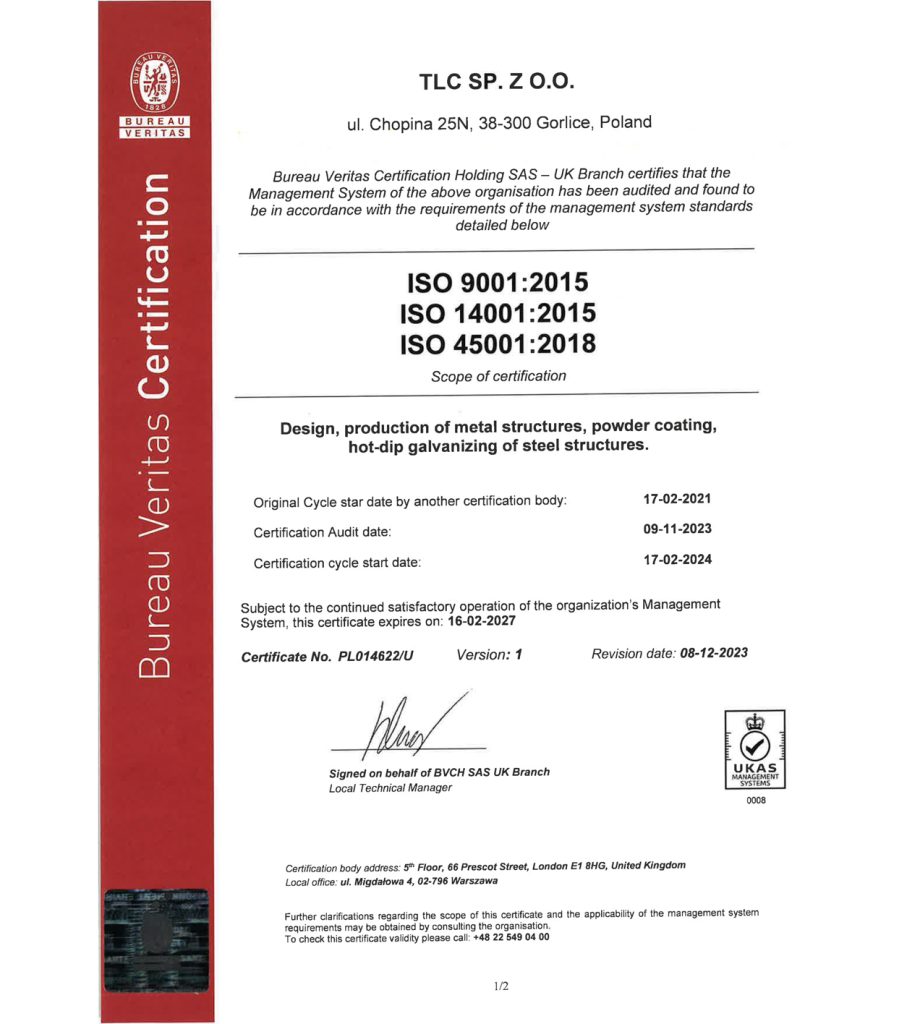

Certification

We ensure that all of our products are of the highest quality through compliance with Factory Manufacture Control certification with EN 1090-1:2009+A1:2011, issued by the TÜV SÜD Polska Sp. z o.o. Certification Centre.

We are a manufacturer with a certificate of the Integrated Quality, Environment and Health and Safety Management System according to ISO 9001/ ISO 14001/ ISO 45001 issued by Bureau Veritas Certification.

Our construction products meet the requirements of the European Directive 305/2011 (CPR) for structural steel and aluminum.

We have Environmental Product Declarations (EPDs) for our products. This is a global Type III declaration programme that follows the principles of ISO 14025. An EPD is a standardised document that provides information on the environmental impact of a product.

Integrated Management System Policy

Gorlice, 1.05.2023, 5th edition

Design, production of metal structures, powder coating, hot-dip galvanzing of steel structures

Bureau Veritas Certification, ISO 9001:2015; ISO 14001:2015; ISO 45001:2018

EPD Environmental Product Declaration

In accordance with ISO 14025:2006 and EN 15804:2012+A2:2019/AC:2021 for: STEEL STAIRS Steel straight/spiral stairs, container stairs P-SK3, 4, 5, 6, 7, 8, SK-KS, TAS and SST temporary stairs, ASTA, CARLA, LINEA modular stairs, industrial communication systems including ladders