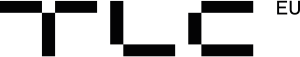

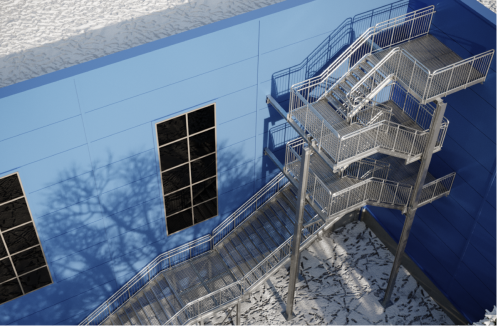

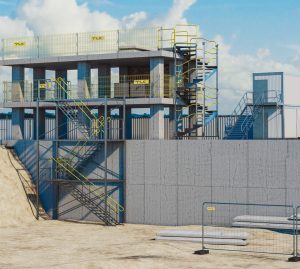

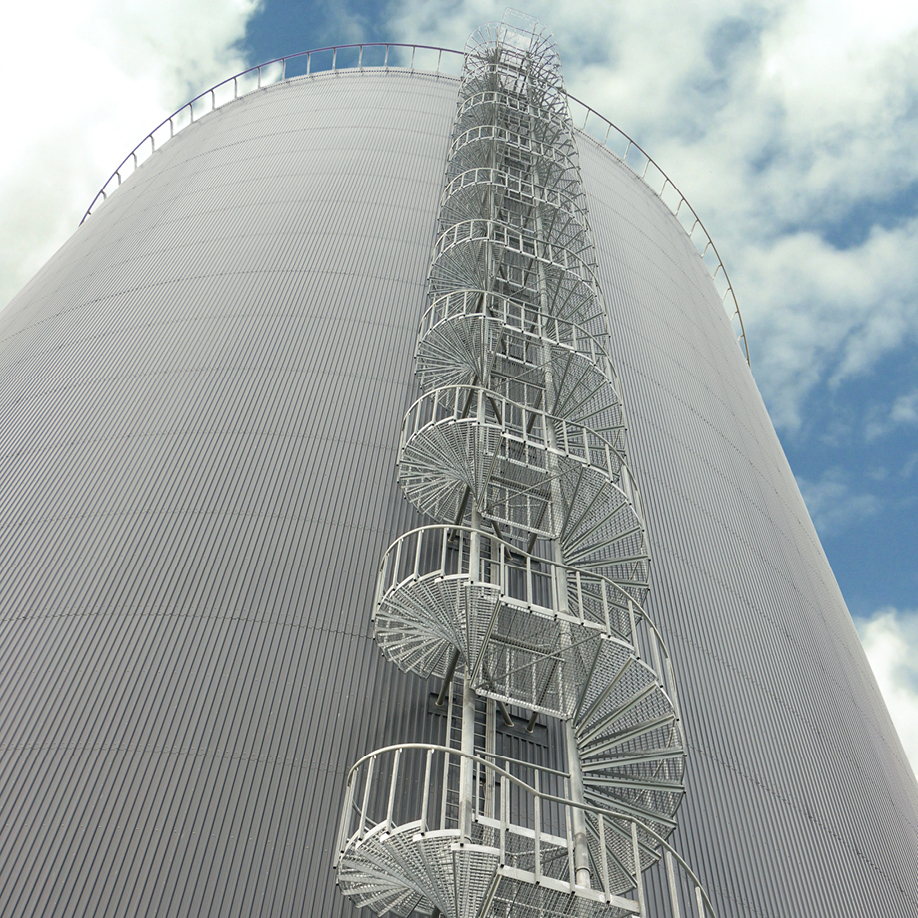

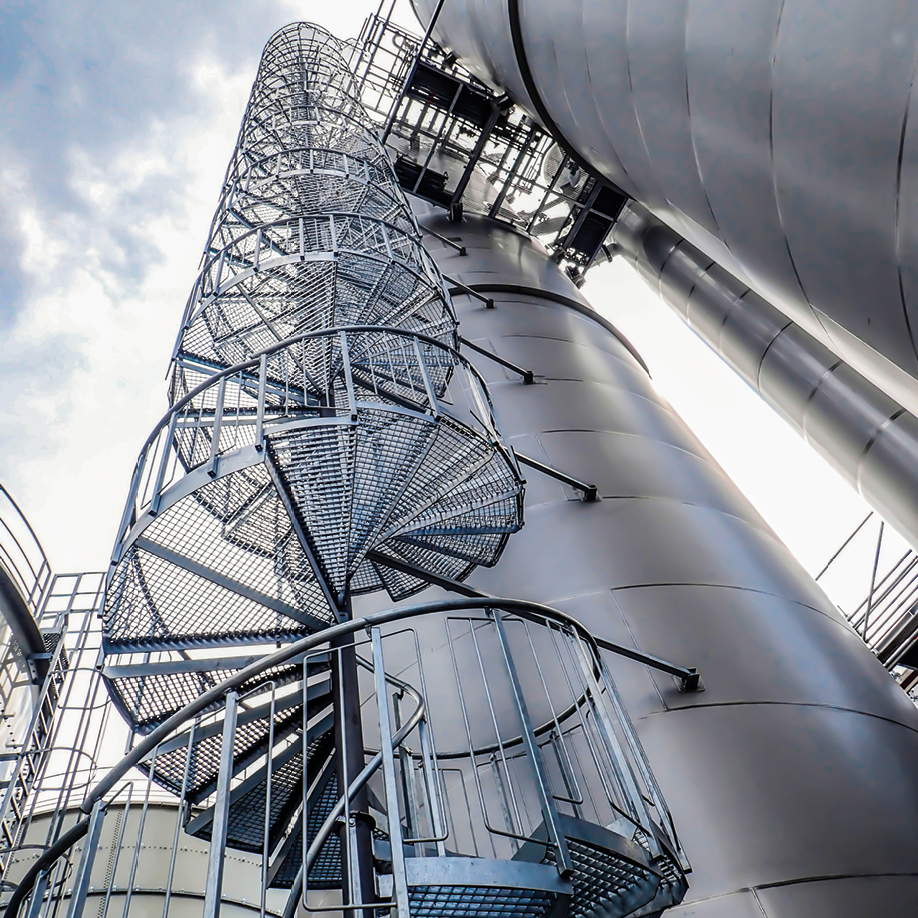

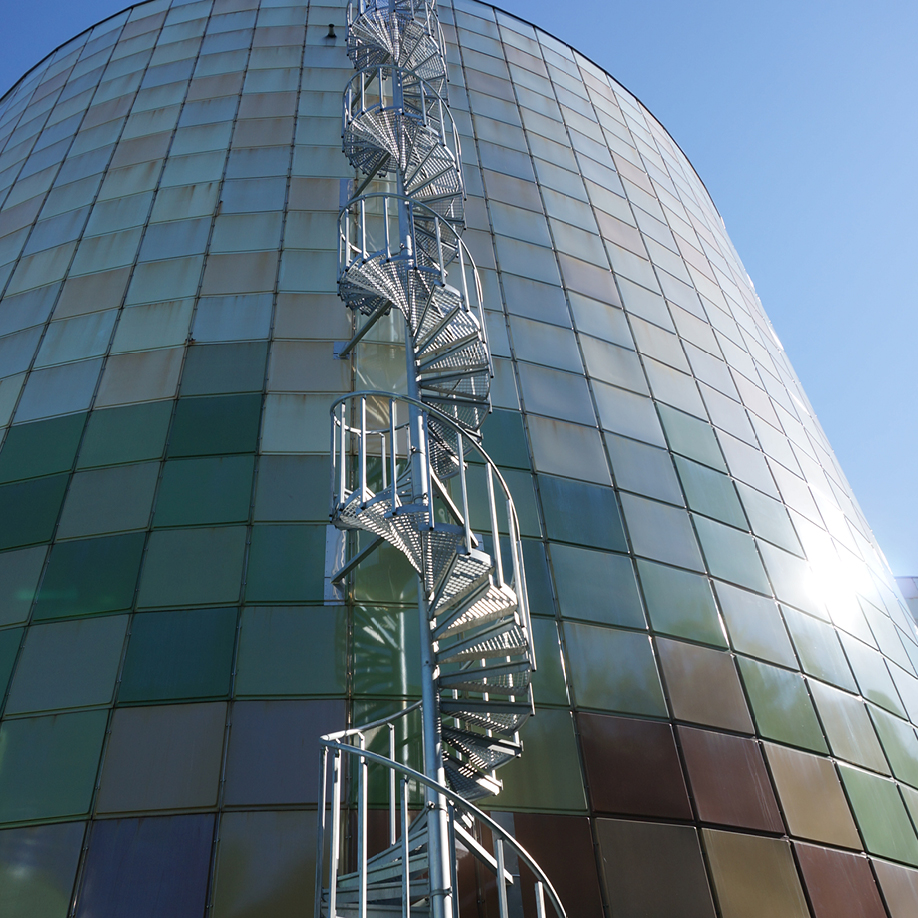

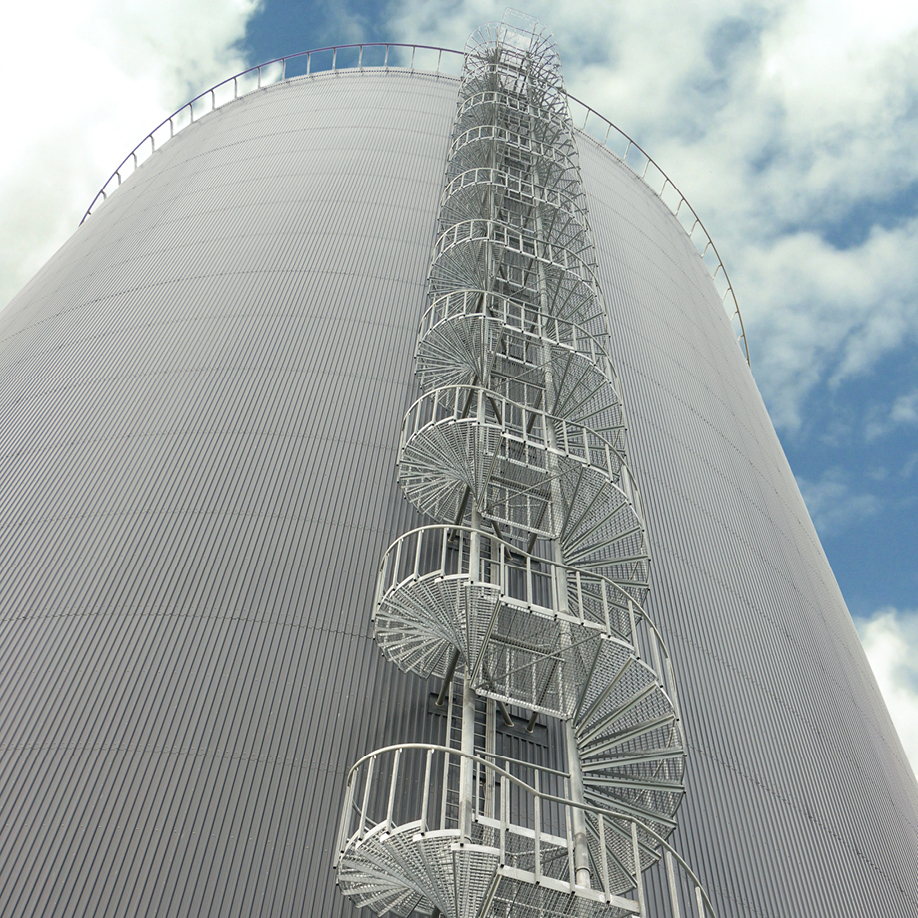

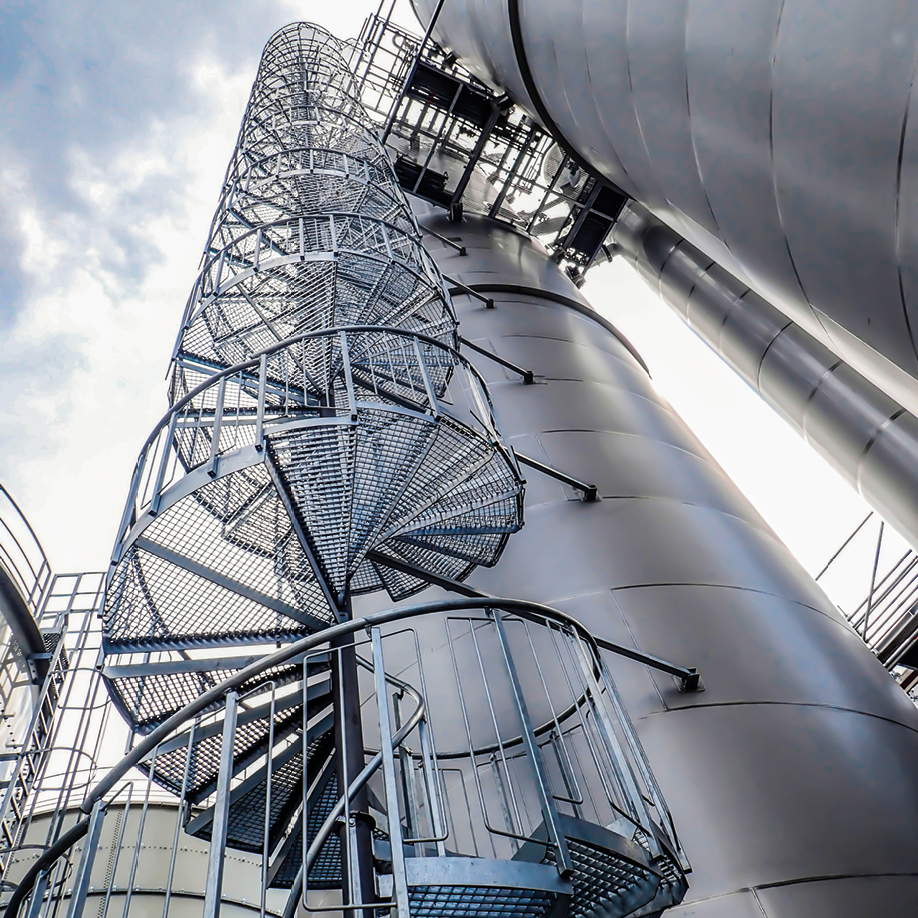

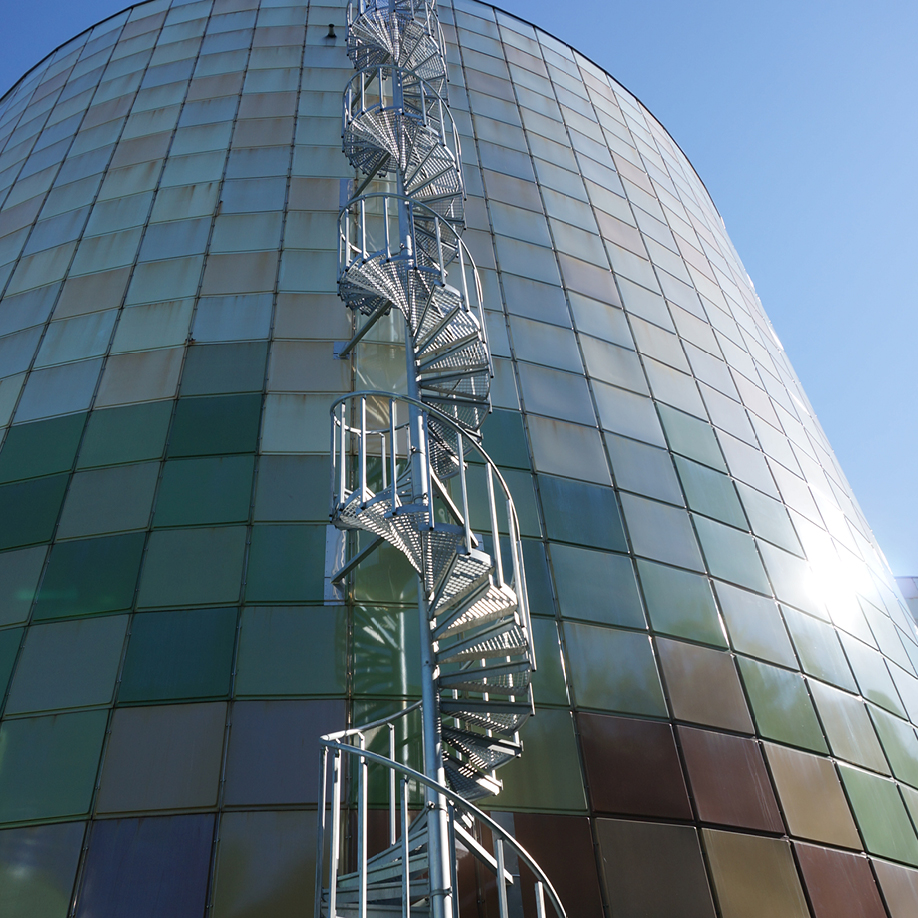

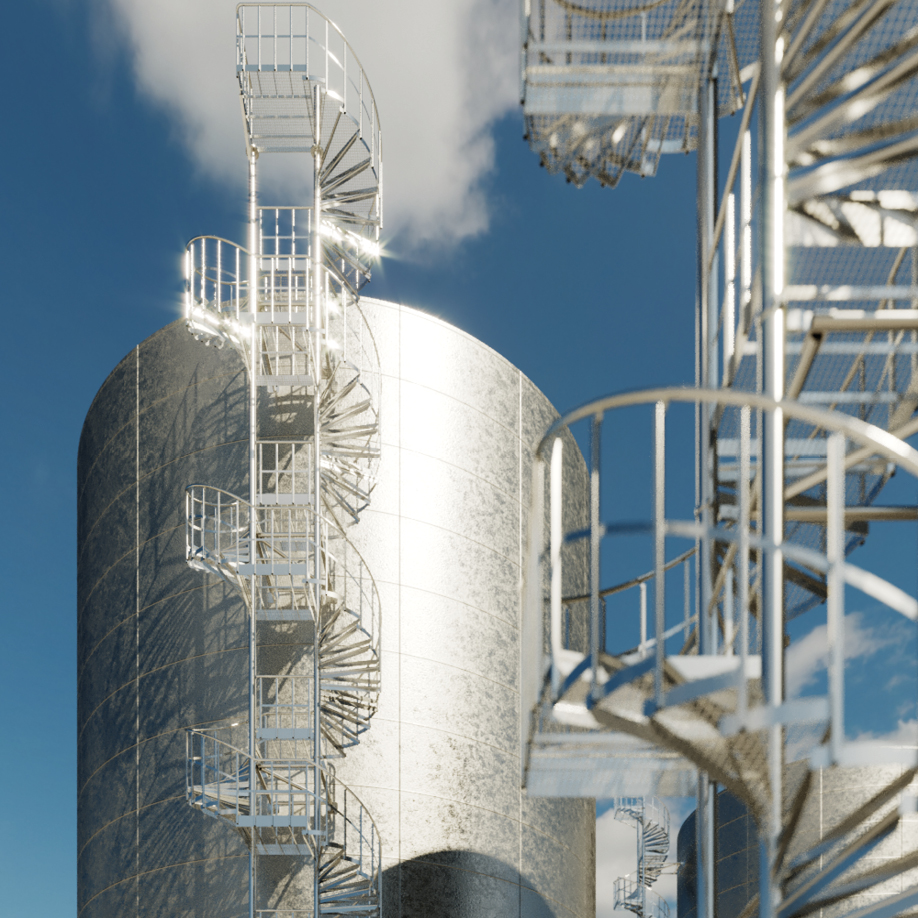

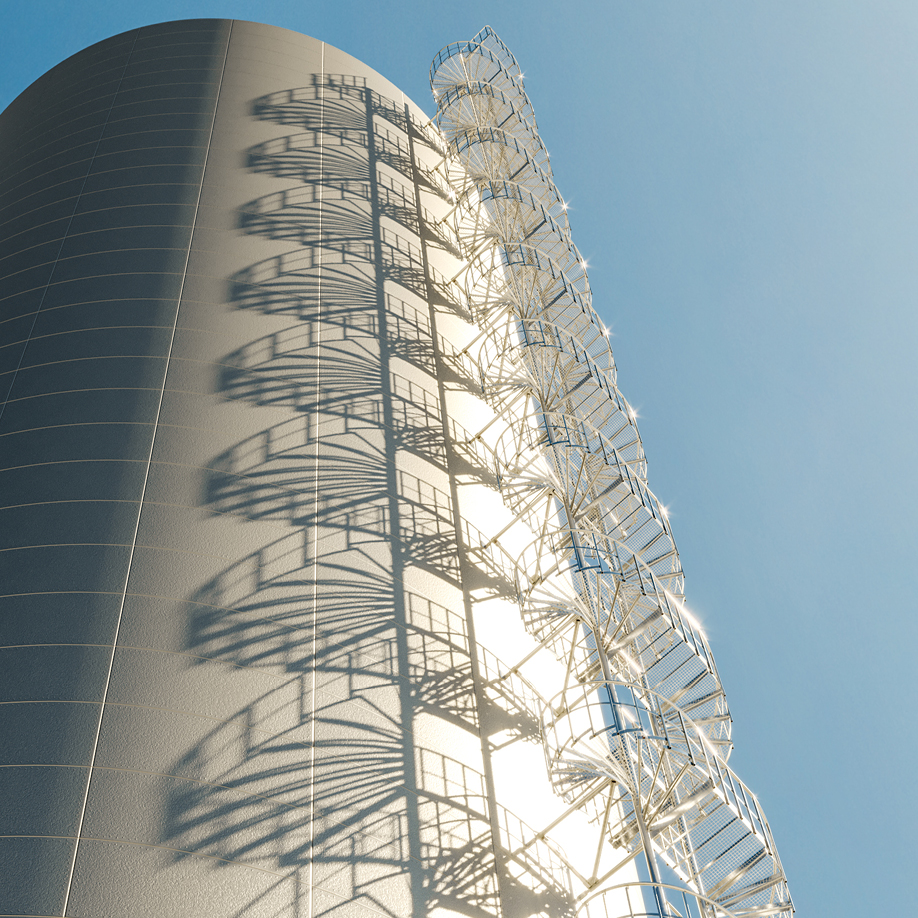

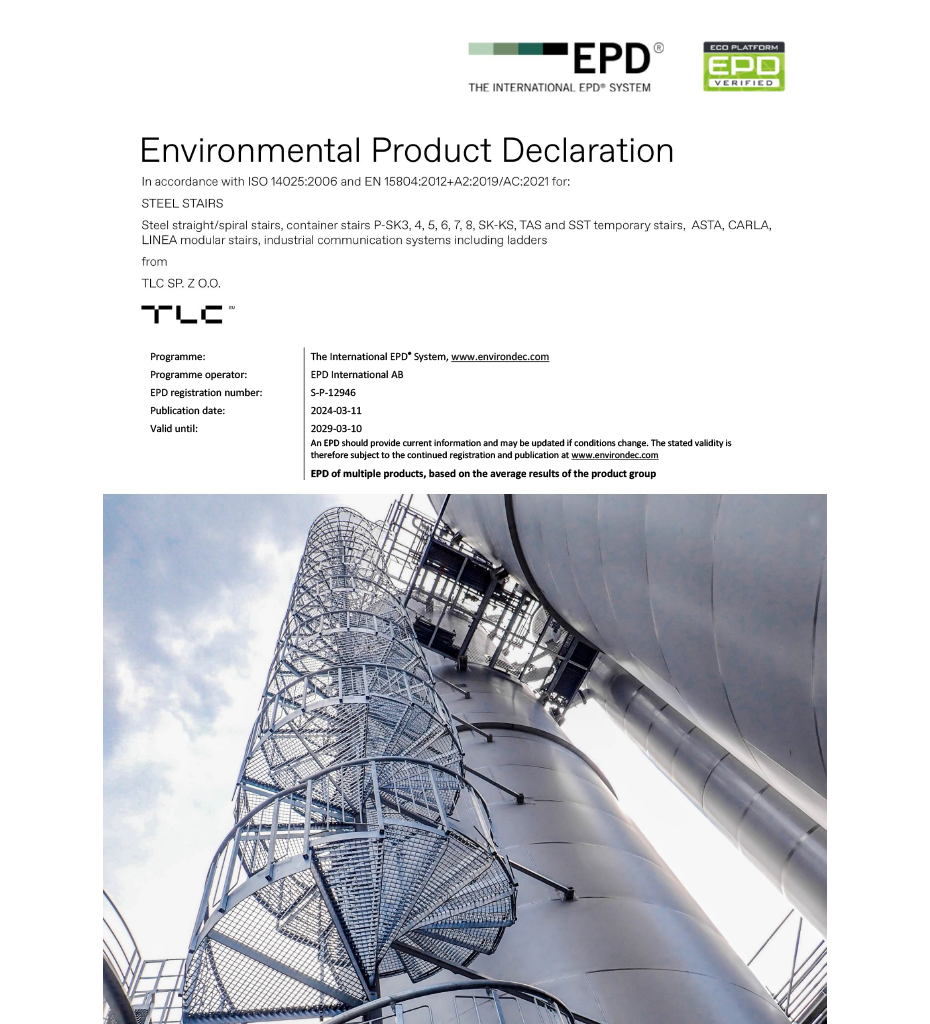

Spiral stairs for tanks

TLC spiral stairs for tanks are durable, safe, and functional solutions designed to provide easy access to large industrial tanks. These stairs are essential in industries such as petrochemicals, energy, water treatment, and food processing, where regular maintenance, inspection, and servicing of tanks are critical for smooth operations.

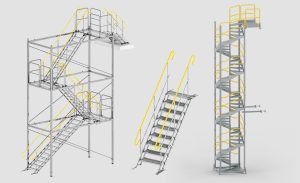

Metal spiral stairs are available in two versions:

- with a central column on hangers

- with a central pole (bushing stairs)

Usage

TLC spiral stairs ensure convenient and safe access to higher sections of tanks, supporting daily operations such as:

- Petrochemical industry

Facilitating access to tanks that store oil, gas, and chemicals. - Energy sector

Providing access to fuel storage tanks and other key industrial installations. - Water and wastewater treatment

Enabling safe access for inspections and cleaning of water storage tanks. - Food industry

Ensuring safe access to tanks storing raw materials and food products while meeting high hygiene standards.

Technical specifications of spiral stairs for tanks

TLC spiral stairs for tanks are built using the highest quality materials, ensuring durability and safety in harsh industrial environments:

- Materials

Made from galvanized steel or stainless steel, the stairs are corrosion-resistant and built to last, even in demanding outdoor conditions. - Safety features

The stairs come with anti-slip steps, handrails, and protective cages, providing maximum safety for operators at different heights. - Standards compliance

The stairs meet international safety standards, including PN ISO 14122, ensuring safe and comfortable access to tanks.

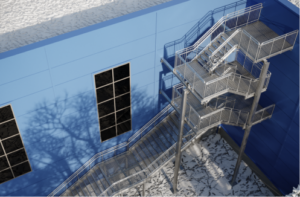

TLC design and offering departments

Our design department allows us to develop innovative and meticulously planned production solutions, maximizing both time and cost efficiency. Our Construction and Technology team is always ready to assist clients in choosing the most appropriate solutions tailored to their specific needs. The Research and Development team continuously works on refining existing solutions and creating new innovations. Our design team minimizes the reliance on external supports, buildings, or brackets. The steps are securely anchored, and the fillings are mounted using spacer connectors.

Our Offering Department provides quick and accurate responses to client inquiries, offering detailed estimates for project costs and timelines. By considering important factors such as materials and weight, they help clients make well-informed decisions. With their expertise, clients receive thorough and reliable project assessments, allowing for efficient planning. The close collaboration between departments ensures smooth execution of projects and customer satisfaction from the initial quote to the project’s completion.

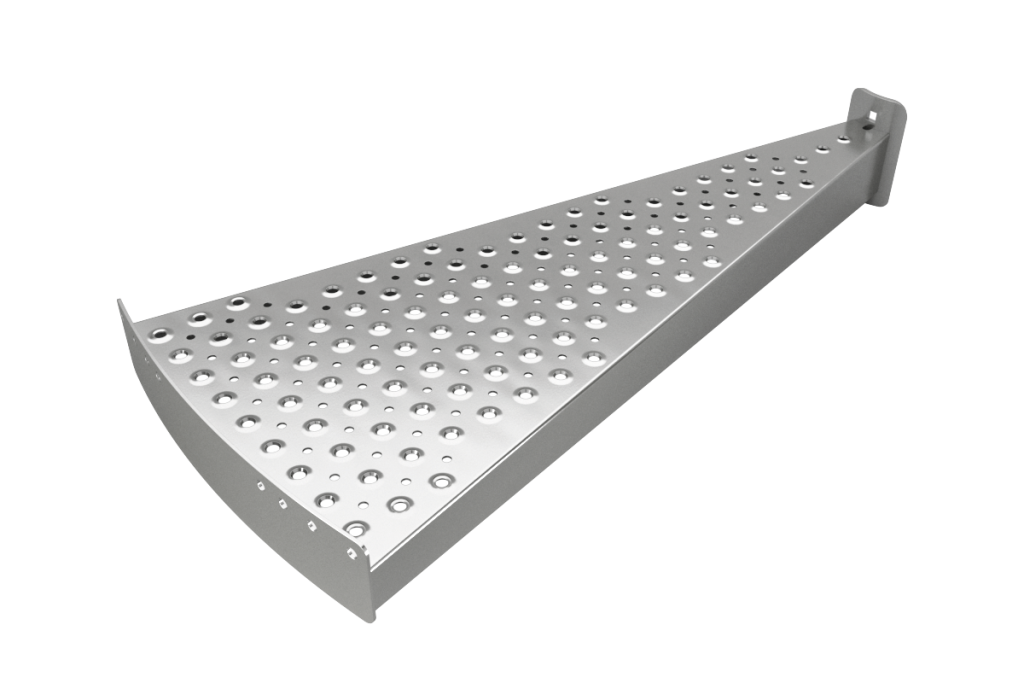

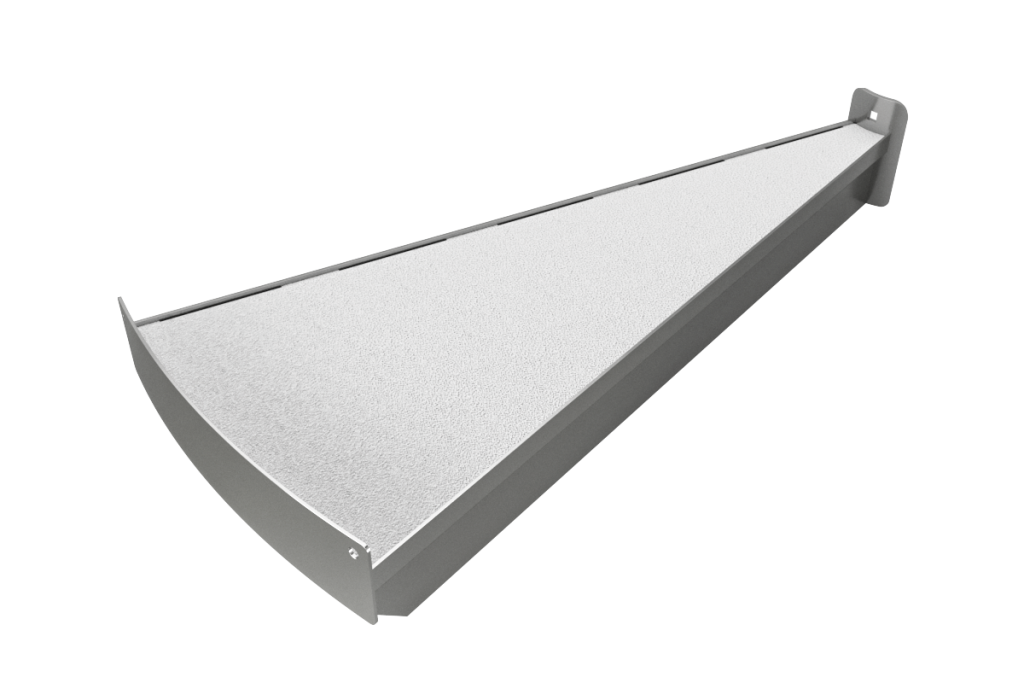

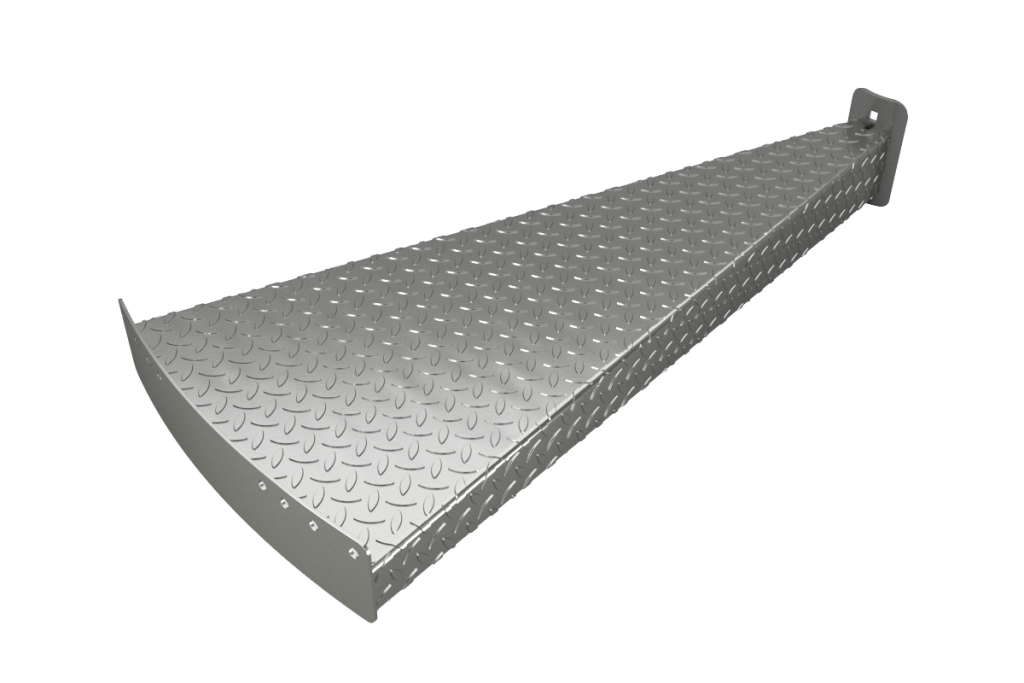

Available types of step filling

- Hot dip galvanized

- Slip resistance DIN 51330: R12

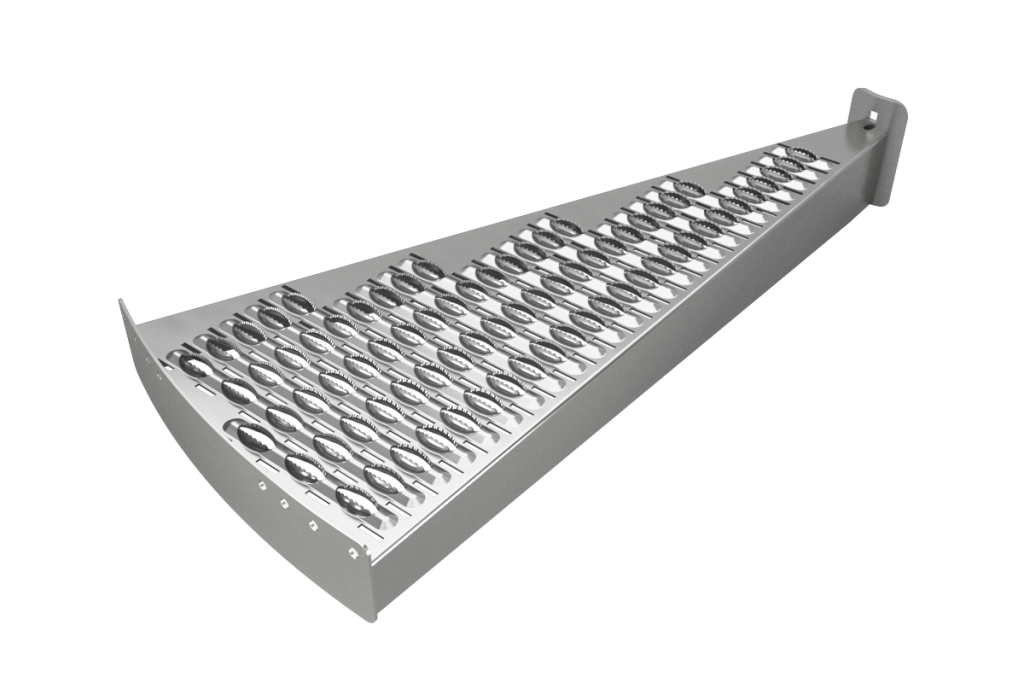

- Hot dip galvanized

- Slip resistance DIN 51130: R12

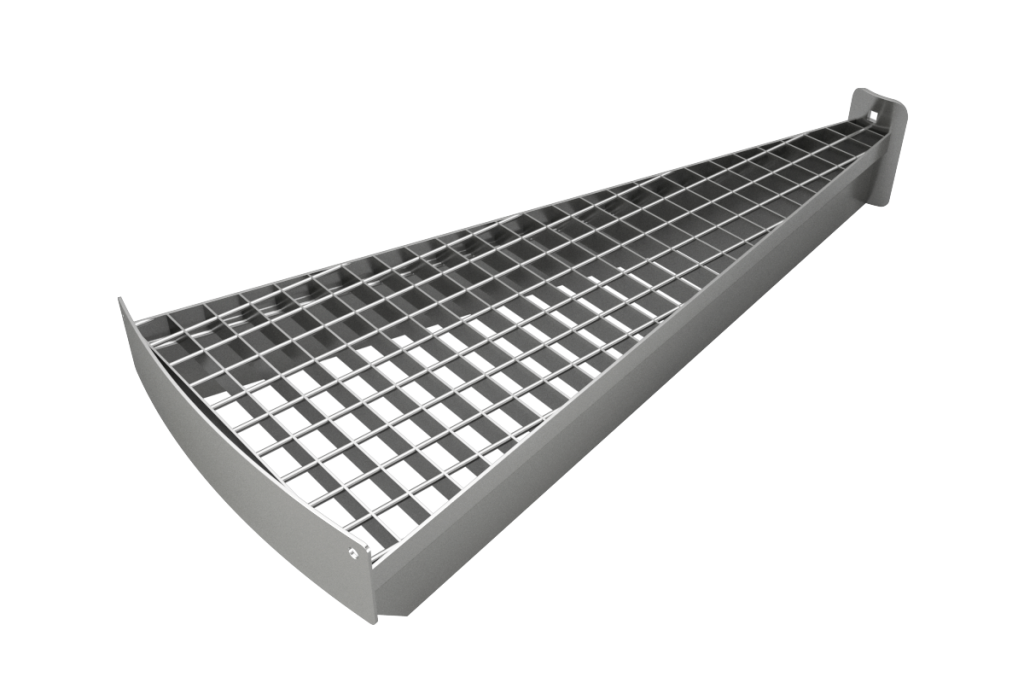

- Mesh 34 x 38

- Hot dip galvanized

- Slip resistance DIN 51130: R10

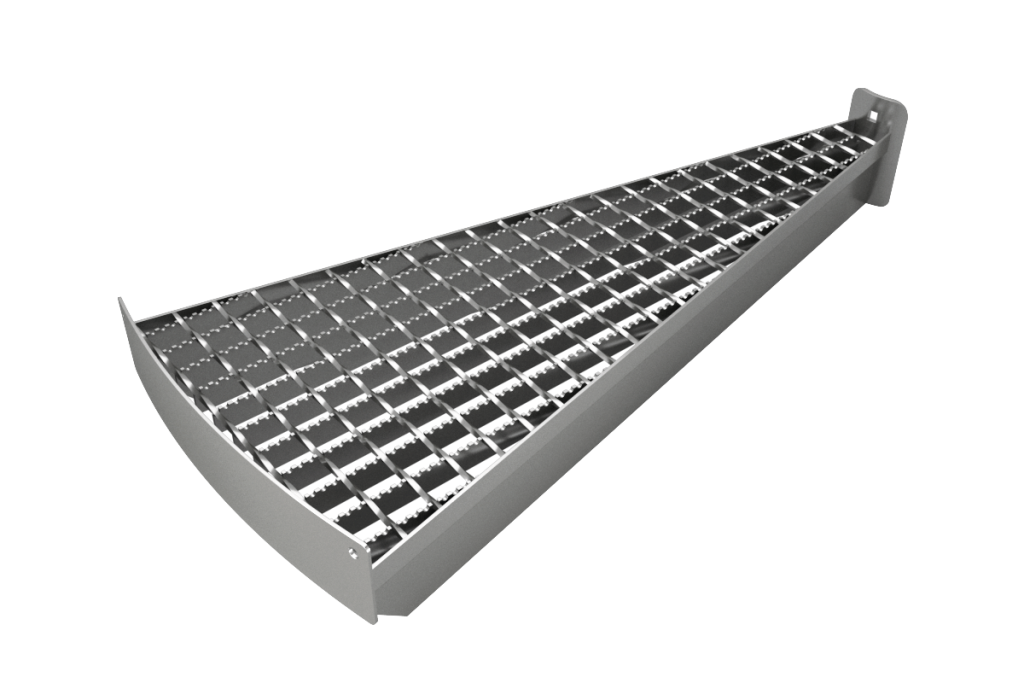

- Mesh 34 x 38

- Hot dip galvanized

- Slip resistance DIN 51130: R11

- Hot dip galvanized

- Powder painted

- Slip resistance DIN 51130: R9

- Hot dip galvanized

- Slip resistance DIN 51130: R10

Available balustrade types

- Rail posts made of square profile 30x30

- Handgrips made of pipe 42,4

- Rail posts made of square profile 30x30

- Handgrips made of pipe 42,4

- Additonal folIower fiat 40x3

- Rail posts made of square profile 30x30 + vertical round bars ø10 mm

- Handgrips made of pipe 42,4

- Rail posts made of square profile 30x30

- Handgrips made of pipe 42,4

- Filling made of 2 pipes 21,3 and vertical round bars 010

Marketing materials

General conditions of sale and installation

Certification

We ensure that all of our products are of the highest quality through compliance with Factory Manufacture Control certification with EN 1090-1:2009+A1:2011, issued by the TÜV SÜD Polska Sp. z o.o. Certification Centre.

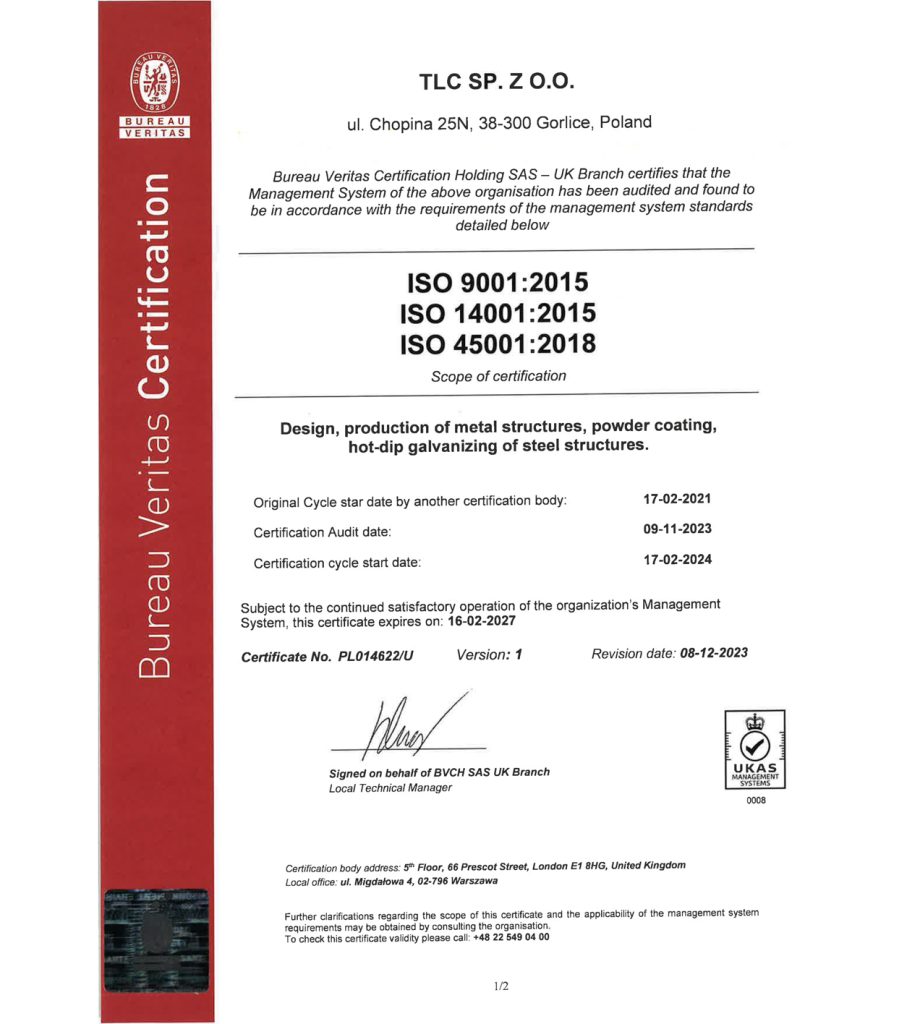

We are a manufacturer with a certificate of the Integrated Quality, Environment and Health and Safety Management System according to ISO 9001/ ISO 14001/ ISO 45001 issued by Bureau Veritas Certification.

Our construction products meet the requirements of the European Directive 305/2011 (CPR) for structural steel and aluminum.

We have Environmental Product Declarations (EPDs) for our products. This is a global Type III declaration programme that follows the principles of ISO 14025. An EPD is a standardised document that provides information on the environmental impact of a product.

Integrated Management System Policy

Gorlice, 1.05.2023, 5th edition

Design, production of metal structures, powder coating, hot-dip galvanzing of steel structures

Bureau Veritas Certification, ISO 9001:2015; ISO 14001:2015; ISO 45001:2018

EPD Environmental Product Declaration

In accordance with ISO 14025:2006 and EN 15804:2012+A2:2019/AC:2021 for: STEEL STAIRS Steel straight/spiral stairs, container stairs P-SK3, 4, 5, 6, 7, 8, SK-KS, TAS and SST temporary stairs, ASTA, CARLA, LINEA modular stairs, industrial communication systems including ladders