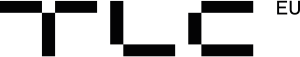

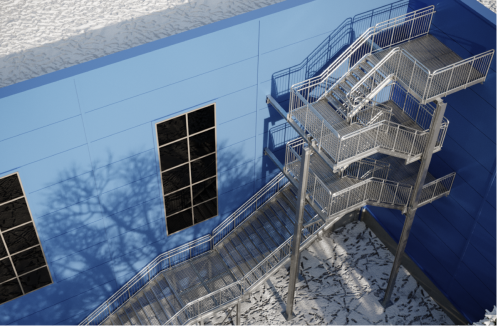

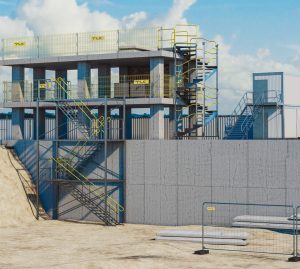

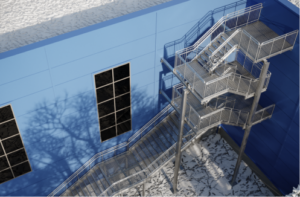

Staircases for tanks

TLC tank staircases are specially designed to provide safe and reliable access to industrial tanks of various sizes. They are essential in facilitating maintenance, inspection, and service work for tanks used in different industries such as petrochemicals, food processing, water treatment, and energy. Built with durability and safety in mind, these stairs meet the highest industrial standards and can be customized to the specific requirements of each installation.

Usage

TLC tank staircases are widely used in many sectors where tanks play a crucial role in operations. Some key applications include:

- Petrochemical industry

Safe access to oil, gas, and chemical tanks for maintenance, inspection, and cleaning. - Water treatment plants

Providing easy access to water storage and treatment tanks for routine inspection and upkeep. - Food and beverage industry

Ensuring safe access to storage tanks for raw materials and finished products, maintaining hygienic standards. - Energy sector

Facilitating the maintenance of fuel storage tanks in power plants and energy facilities.

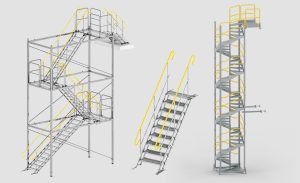

Key Features

- Durable construction

TLC tank staircases are made from high-quality galvanized steel to ensure durability and resistance to corrosion, even in harsh environments. - Customizable design

The stairs can be tailored to fit the height and dimensions of any tank, with options for protective cages and additional safety features such as guardrails and anti-slip surfaces. - Safety compliance

Designed in accordance with international safety standards, TLC tank stairs provide safe and secure access at any height, ensuring worker protection during maintenance tasks.

TLC design and estimate departments

Thanks to our in-house design department, we are able to develop a tailor-made design for various types of large tanks, both fixed roof and floating roof containers.

Our research and development department constantly works on improving existing solutions and creating new ones. TLC also specializes in the design and manufacture of spiral stairs, arched stairs, and hybrid structures. Our design team focuses on minimizing the need for external brackets, buildings, or additional supports.

The estimate department ensures a quick response to client inquiries, providing precise estimates for project costs and timelines. By taking into account key factors such as materials, they assist clients in making well-informed decisions. Thanks to their expertise, clients receive thorough and dependable project assessments, enabling efficient planning. The close cooperation between departments guarantees smooth execution and customer satisfaction from the initial quote to the final project handover.

Standards for steel staircases

Steel staircases produced by TLC comply with both Polish and international standards. For industrial access stairs, the applicable standard is PN ISO 14122. Ensuring reliability and safety is a top priority when designing these staircase structures. The relevant standards include:

- PN-EN_1990_2004: Basis of Structural Design

- PN-EN-1991-1-2 (2006): Actions on Structures – Actions on Structures in Fire Conditions

- PN-EN-1993-1-2 (2007): Design of Steel Structures – Design for Fire Conditions

- PN-EN 1992 Eurocode 2: Design of Concrete Structures

- EOTA – 11/0014 – Sika Unitherm Platinum

- ECCS N89 – Euro Nomogram – Fire Resistance of Steel Structures

- Access Steel – Guidelines for Designing Steel Structures

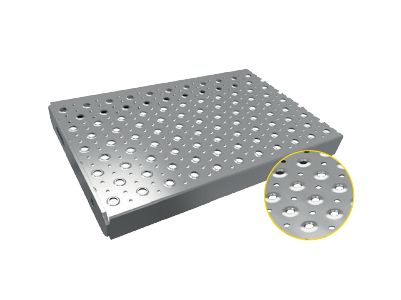

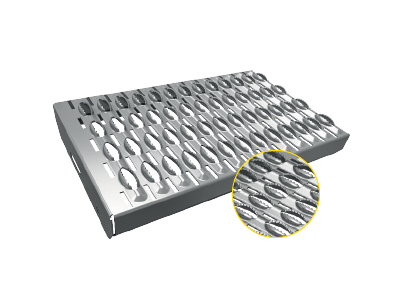

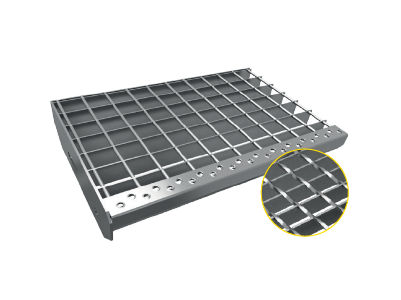

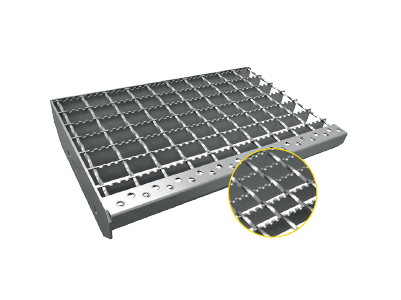

Available types of step filling

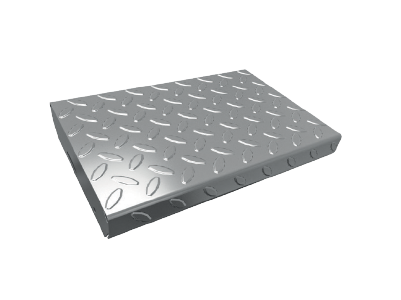

- Hot dip galvanized

- Slip resistance DIN 51130: R12

- Hot dip galvanized

- Slip resistance DIN 51130: R12

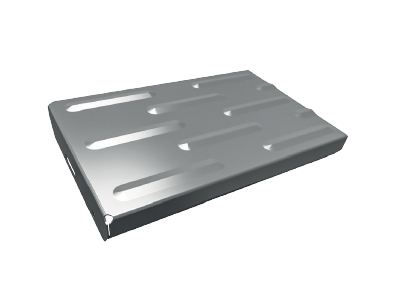

- Mesh 34 x 38

- Hot dip galvanized

- Slip resistance DIN 51130: R10

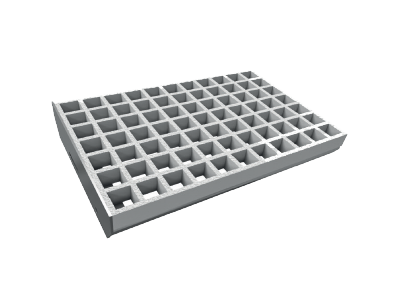

- Mesh 34 x 38

- Hot dip galvanized

- Slip resistance DIN 51130: R11

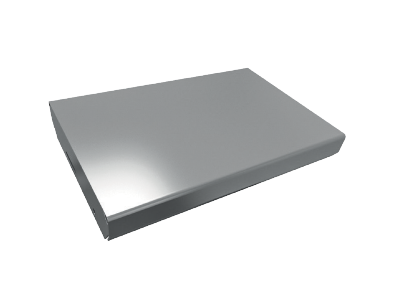

- Hot dip galvanized

- Slip resistance DIN 51130: R10

- Hot dip galvanized

- Powder painted

- Slip resistance DIN 51130: R9

- Hot dip galvanized

- Slip resistance DIN 51130: R9

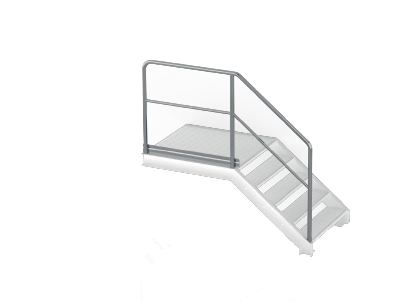

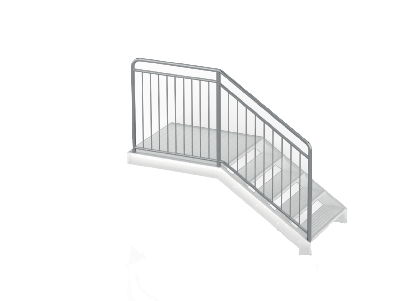

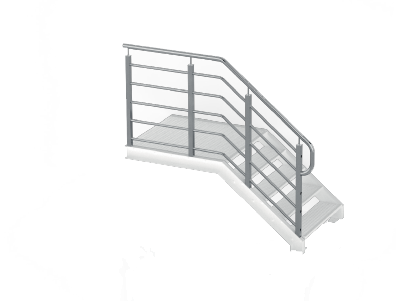

Available balustrade types

- Handgrip and railposts made of circular pipe ø42,4

- Middle bar made of circular pipe ø26,9

- Equipped with kickplate – 100 or 150 high, #1,5 or #2 thickness depending on width of railing

- Handgrip made of circular pipe ø42,4

- Railposts made of circular pipe ø42,4

- Two followers made of circular pipe ø26,9

- Filling of vertical round bars ø12

- Handgrip made of circular pipe ø48,3

- Railposts made of square profile 50x50

- Filling of horizontal circular pipe ø25

Marketing materials

General conditions of sale and installation

Certification

We ensure that all of our products are of the highest quality through compliance with Factory Manufacture Control certification with EN 1090-1:2009+A1:2011, issued by the TÜV SÜD Polska Sp. z o.o. Certification Centre.

We are a manufacturer with a certificate of the Integrated Quality, Environment and Health and Safety Management System according to ISO 9001/ ISO 14001/ ISO 45001 issued by Bureau Veritas Certification.

Our construction products meet the requirements of the European Directive 305/2011 (CPR) for structural steel and aluminum.

We have Environmental Product Declarations (EPDs) for our products. This is a global Type III declaration programme that follows the principles of ISO 14025. An EPD is a standardised document that provides information on the environmental impact of a product.

Integrated Management System Policy

Gorlice, 1.05.2023, 5th edition

Design, production of metal structures, powder coating, hot-dip galvanzing of steel structures

Bureau Veritas Certification, ISO 9001:2015; ISO 14001:2015; ISO 45001:2018

EPD Environmental Product Declaration

In accordance with ISO 14025:2006 and EN 15804:2012+A2:2019/AC:2021 for: STEEL STAIRS Steel straight/spiral stairs, container stairs P-SK3, 4, 5, 6, 7, 8, SK-KS, TAS and SST temporary stairs, ASTA, CARLA, LINEA modular stairs, industrial communication systems including ladders