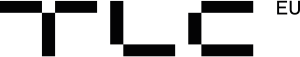

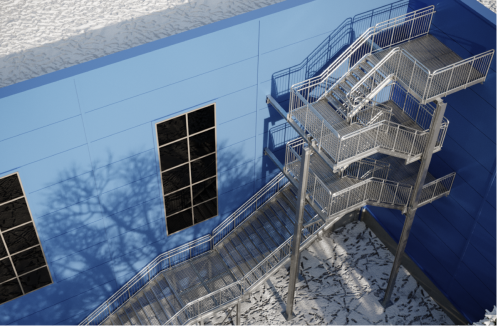

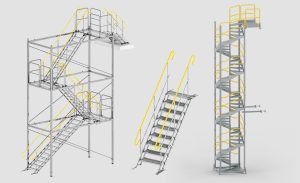

Straight stairs

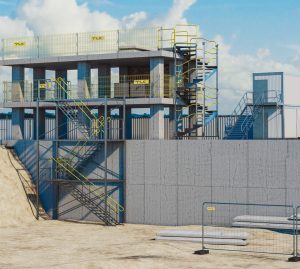

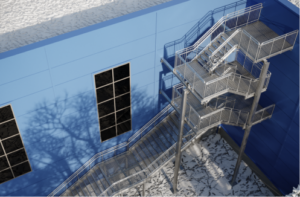

Straight stairs are durable steel structures designed for both exterior and interior access to buildings with diverse functions. They function as both service stairs and emergency exits. Thanks to the flexibility of custom design, TLC-produced staircases comply with all functional standards. Additionally, they are tailored to meet the specific requirements, codes, and regulations of each country.

Straight steel staircases play a critical role in various industries. With our in-house hot-dip galvanizing and powder coating capabilities, we ensure top-tier corrosion resistance for the structures.

Usage

Staircases are a popular form of passageway design in industrial facilities. Like straight stairs, they are typically used in facilities such as:

- Production halls

- Logistics halls

- Machinery parks factories

- Warehouses

- Cold storage facilities

- Sorting plants and waste incineration plants

- Public areas

In addition, stairs can be used to access the storage containers. The assembly of the supporting structure, steps, railings and platforms is carried out by screw connections with support brackets, or a self-supporting structure is prepared, which usually rests on pillars.

Standards for steel stairs

- Top-Quality Materials

We guarantee superior quality at every stage of production by using metal construction materials sourced from trusted suppliers. - Safety Above

All Safety is our top priority. Customize your staircase with different types of steps and railings from our comprehensive selection. - Expert Protection

Ensure full protection with our expert solutions, featuring durable steps and railings designed for optimal safety and performance. Every component is preserved with hot dip galvanization process according to EN ISO 1461 (DIN 50976) standard, spray painted or powder coated using RAL colors or NCS colors (optionally).

TLC design and estimate departments

Our design department allows us to create innovative and meticulously planned solutions for straight stairs, optimizing both time and cost efficiency.

The construction and technology team is always available to assist clients in selecting the most appropriate design that meets their specific requirements. Our research and development team is continuously focused on enhancing existing designs and introducing new innovations for straight staircases.

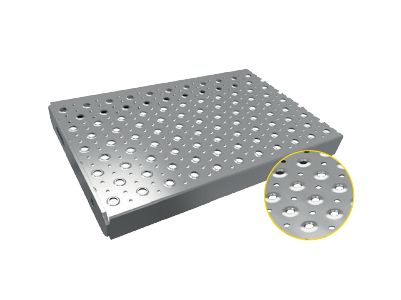

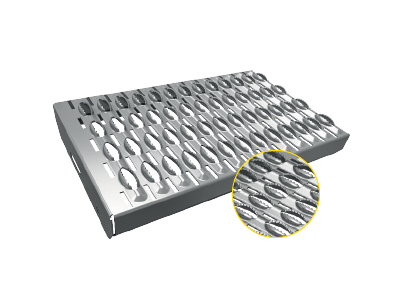

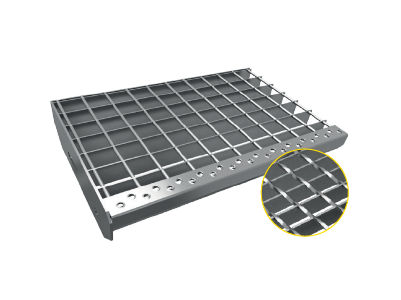

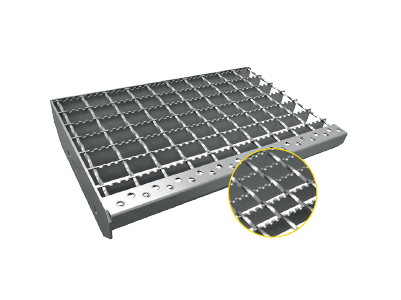

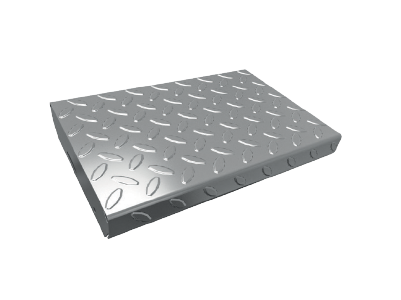

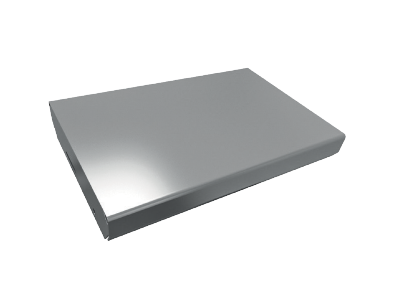

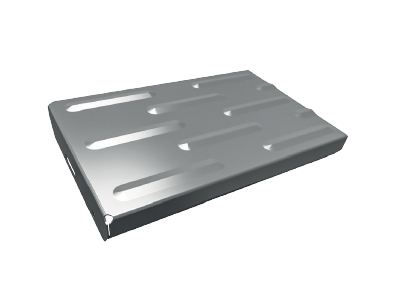

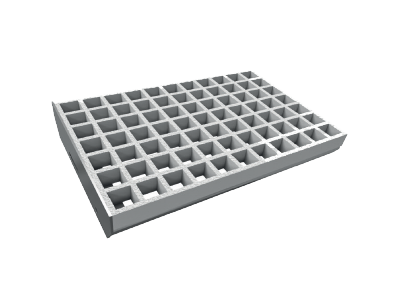

Available types of step filling

- Hot dip galvanized

- Slip resistance DIN 51130: R12

- Hot dip galvanized

- Slip resistance DIN 51130: R12

- Mesh 34 x 38

- Hot dip galvanized

- Slip resistance DIN 51130: R10

- Mesh 34 x 38

- Hot dip galvanized

- Slip resistance DIN 51130: R11

- Hot dip galvanized

- Slip resistance DIN 51130: R10

- Hot dip galvanized

- Powder painted

- Slip resistance DIN 51130: R9

- Hot dip galvanized

- Slip resistance DIN 51130: R9

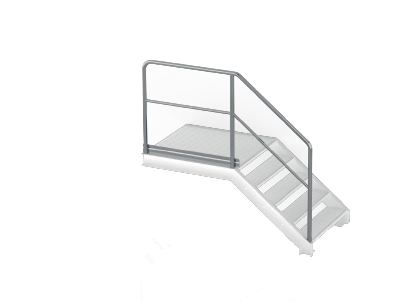

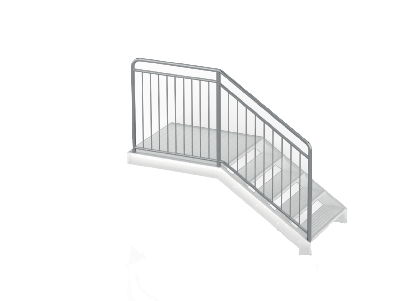

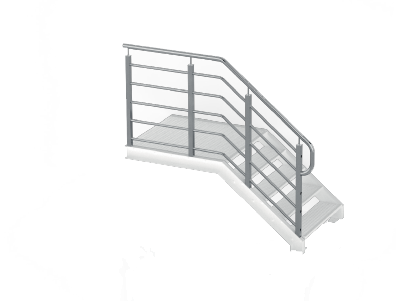

Available balustrade types

- Handgrip and railposts made of circular pipe ø42,4

- Middle bar made of circular pipe ø26,9

- Equipped with kickplate – 100 or 150 high, #1,5 or #2 thickness depending on width of railing

- Handgrip made of circular pipe ø42,4

- Railposts made of circular pipe ø42,4

- Two followers made of circular pipe ø26,9

- Filling of vertical round bars ø12

- Handgrip made of circular pipe ø48,3

- Railposts made of square profile 50x50

- Filling of horizontal circular pipe ø25

Marketing materials

General conditions of sale and installation

Certification

We ensure that all of our products are of the highest quality through compliance with Factory Manufacture Control certification with EN 1090-1:2009+A1:2011, issued by the TÜV SÜD Polska Sp. z o.o. Certification Centre.

We are a manufacturer with a certificate of the Integrated Quality, Environment and Health and Safety Management System according to ISO 9001/ ISO 14001/ ISO 45001 issued by Bureau Veritas Certification.

Our construction products meet the requirements of the European Directive 305/2011 (CPR) for structural steel and aluminum.

We have Environmental Product Declarations (EPDs) for our products. This is a global Type III declaration programme that follows the principles of ISO 14025. An EPD is a standardised document that provides information on the environmental impact of a product.

Integrated Management System Policy

Gorlice, 1.05.2023, 5th edition

Design, production of metal structures, powder coating, hot-dip galvanzing of steel structures

Bureau Veritas Certification, ISO 9001:2015; ISO 14001:2015; ISO 45001:2018

EPD Environmental Product Declaration

In accordance with ISO 14025:2006 and EN 15804:2012+A2:2019/AC:2021 for: STEEL STAIRS Steel straight/spiral stairs, container stairs P-SK3, 4, 5, 6, 7, 8, SK-KS, TAS and SST temporary stairs, ASTA, CARLA, LINEA modular stairs, industrial communication systems including ladders