Comprehensive system of aircraft maintenance platforms

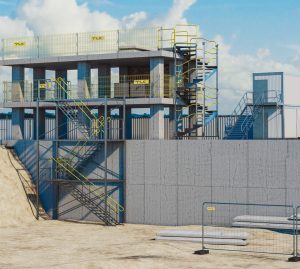

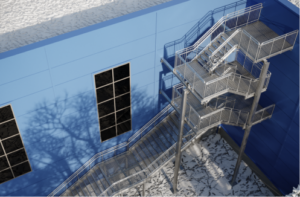

For one of Europe’s leading aircraft manufacturers, TLC developed a set of three service platforms designed directly on the basis of the client’s technical documentation and adapted to the specific requirements of aircraft maintenance operations.

Project scope – three coordinated service platforms

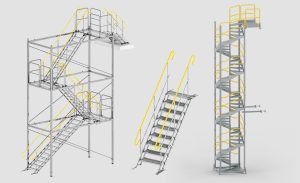

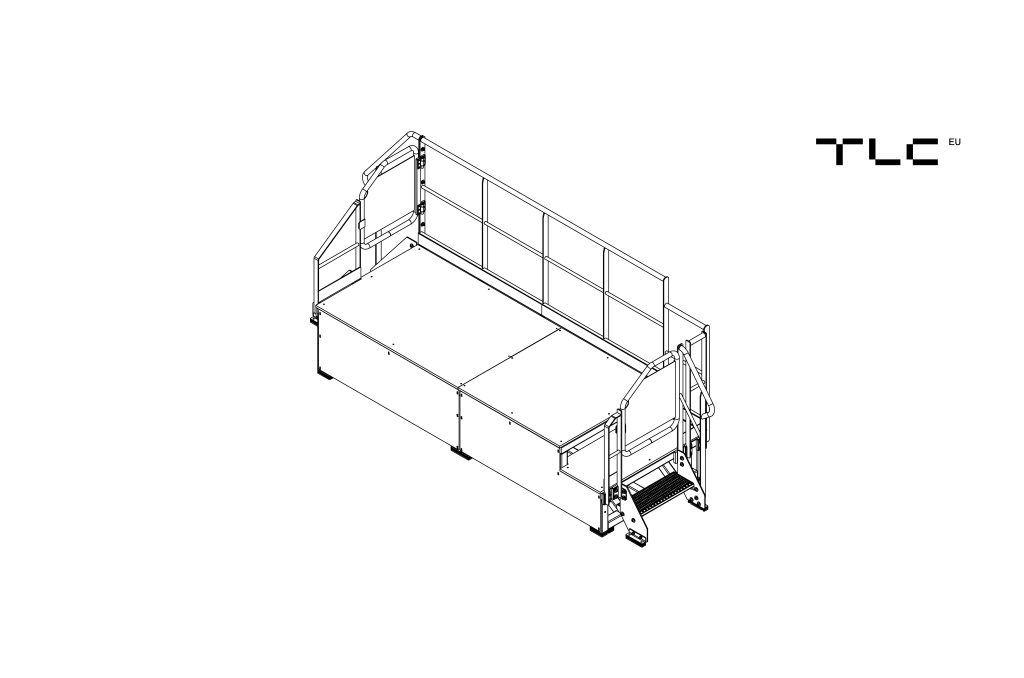

Main service platform – safe operation at the required height

The central working platform, serving as the primary maintenance area, was equipped with:

- access stairs with handrails on both sides,

- protective railings and side guards,

- an anti-slip working surface in RAL 7040,

- recessed deck lighting,

- access from two sides — from the front and the side.

All steel components were coated with anti-corrosion finishes in RAL 7035, RAL 9016 and RAL 3001, selected for environments operating near coastal conditions.

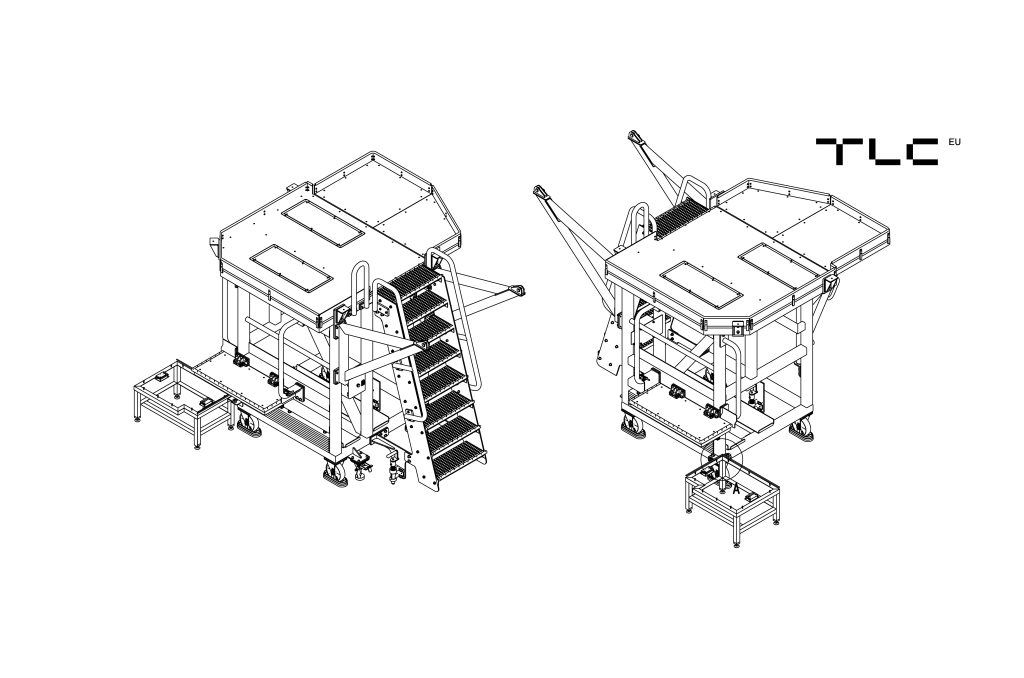

Mobile platform – flexible positioning and smooth adjustment

This platform is intended for maintenance tasks requiring frequent changes of position. It incorporates:

- rotating locking arms securing the working position,

- bushings and slide bearings ensuring smooth movement,

- gas springs supporting adjustment,

- opening side service platforms increasing the working range.

These features make it possible to precisely position the platform in various aircraft fuselage zones.

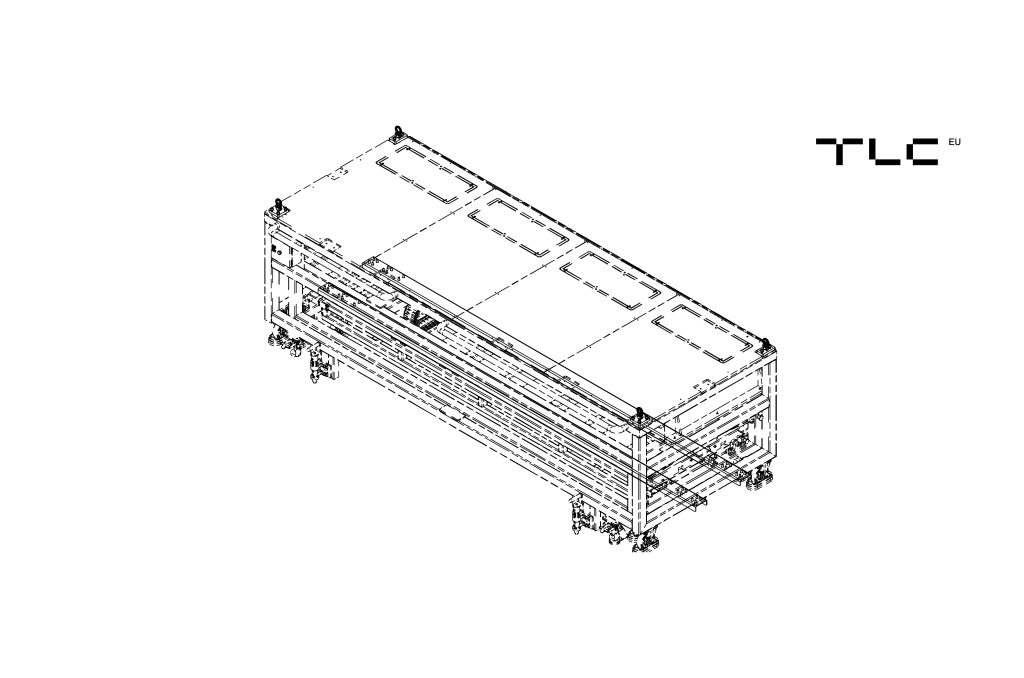

Segmental platform – efficient transport and fast assembly

The third platform was designed as a modular structure suitable for long-distance transport:

- ability to be divided into six segments,

- bolted connections,

- anti-corrosion coating ensuring durability during storage and operation.

This solution simplifies logistics and allows accurate reassembly at the place of use.

Technical solutions engineered for aviation environments

Each platform is equipped with features that enhance safety and operational efficiency:

- suspended guiding system enabling linear movement,

- additional counterweights increasing overall stability,

- foot brake integrated with the running gear,

- circumferential welds improving resistance to corrosion,

- anti-slip working surfaces and recessed lighting.

All components were produced on time and in accordance with the highest quality standards. The final structure reflects a comprehensive engineering approach to designing maintenance platforms for the aviation sector.

Project details

Project: E/6495

Scope: three aircraft service platforms

Sector: aerospace

Corrosion protection: hot-dip galvanization

Contact us

Contact us to find out how TLC can support your projects.

Want to learn more? Check out the full case study for detailed information and technical insights: read the case study.

See our other projects

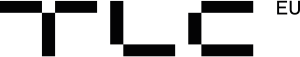

Steel staircase for a food industry facility in Poland

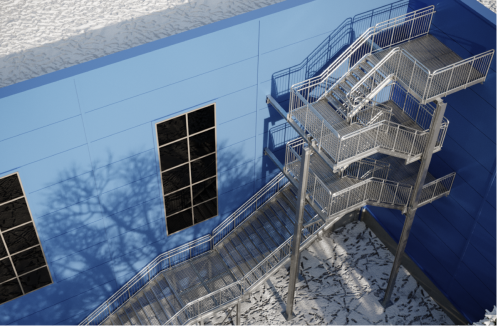

External spiral staircase and service platforms for industrial tanks