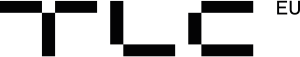

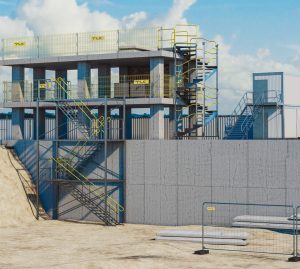

Phosphoric acid tank construction by Nordweld and TLC in Finland

Project number: D/6074/01

In January 2024, TLC and Nordweld joined forces to collaboratively undertake the construction of a phosphoric acid tank in Finland, emphasizing the comprehensiveness of the project.

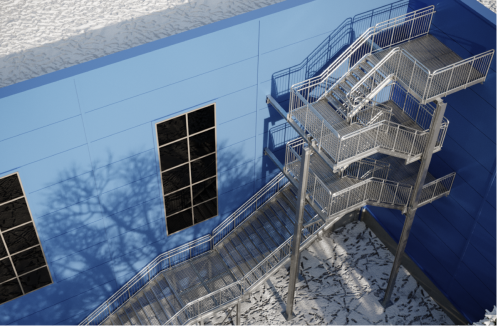

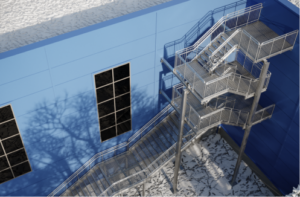

Nordweld was responsible for the construction of the phosphoric acid tank, while TLC designed the comprehensive communication routes on the tank and provided the stairs. Our solutions not only facilitated access to the tank but also ensured safety and convenience during its use.

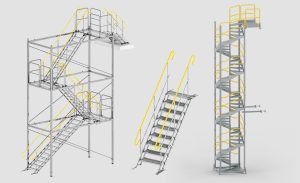

Details of the stairs and platforms:

- Height of Stairs: 21,224 mm

- Width of Stairs: 800 mm

- Step Dimensions: 270×800 mm

- Handrails: Industrial standard, 1200 mm high on both sides, with a 140 mm high guard.

- Specification of Steps and Platforms:

– Steps: 34×38 30×3 with serrated finish

– Platforms: 34×38 30×3 with serrated finish - Zinc Coating: Hot-dip galvanizing according to ISO 1461 HDG, corrosion class C3 for grating.

- Paint System (EN ISO 12944):

– Handrails: HDG + RAL 1021 (corrosion class C4)

– Frames: HDG + RAL 5007 (corrosion class C4) - Contrast Marking: Black contrast marking, 100 mm wide, on the first and last step.

- Usage Category (EN-ISO-14122):

– Stairs and Platforms: Designed for a load of 2.0 kN/m²

– Handrails: Designed for a load of 0.3 kN/m

Phosphoric Acid Tank:

- Diameter: 19 m

- Height: 18 m, including external overflow pipe, stairs, and platforms

- Weight: 158 t

- Material: Duplex stainless steel 1.4462

Gallery

See our other projects

Steel staircase for a food industry facility in Poland

External spiral staircase and service platforms for industrial tanks