TAS temporary staircase

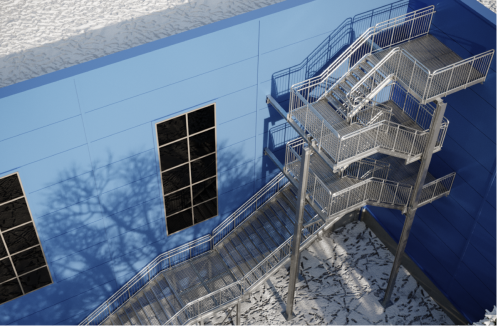

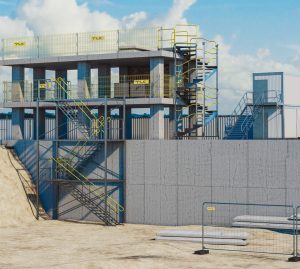

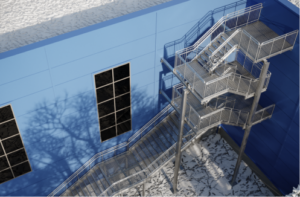

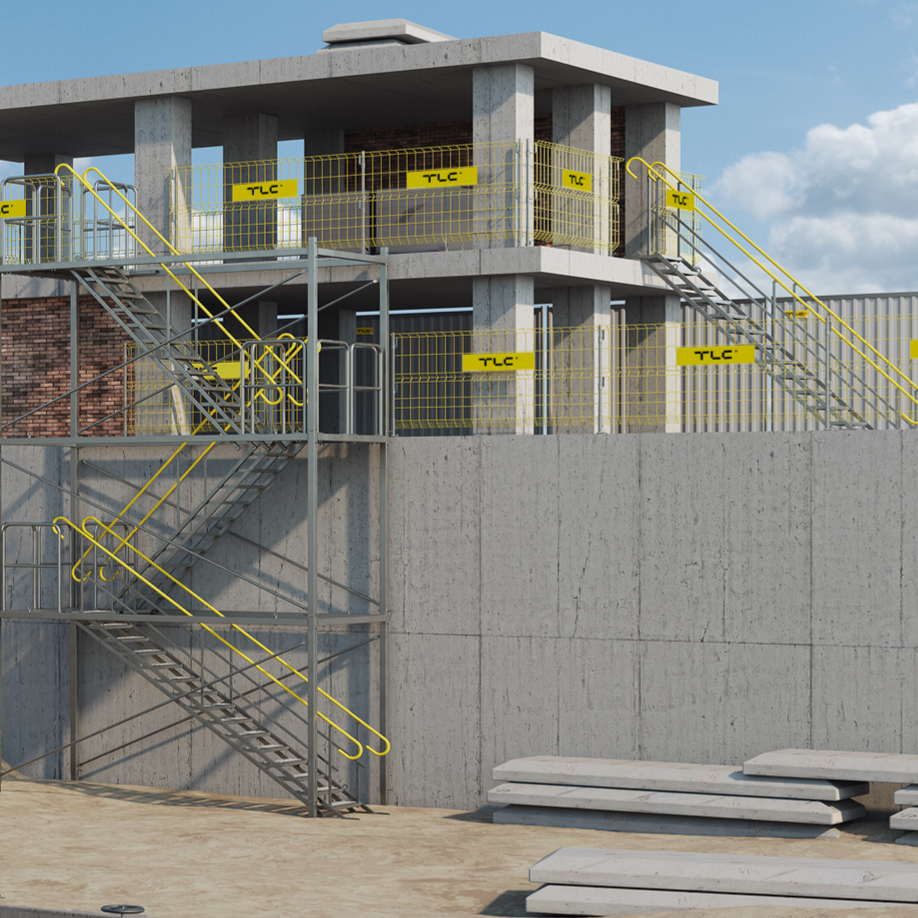

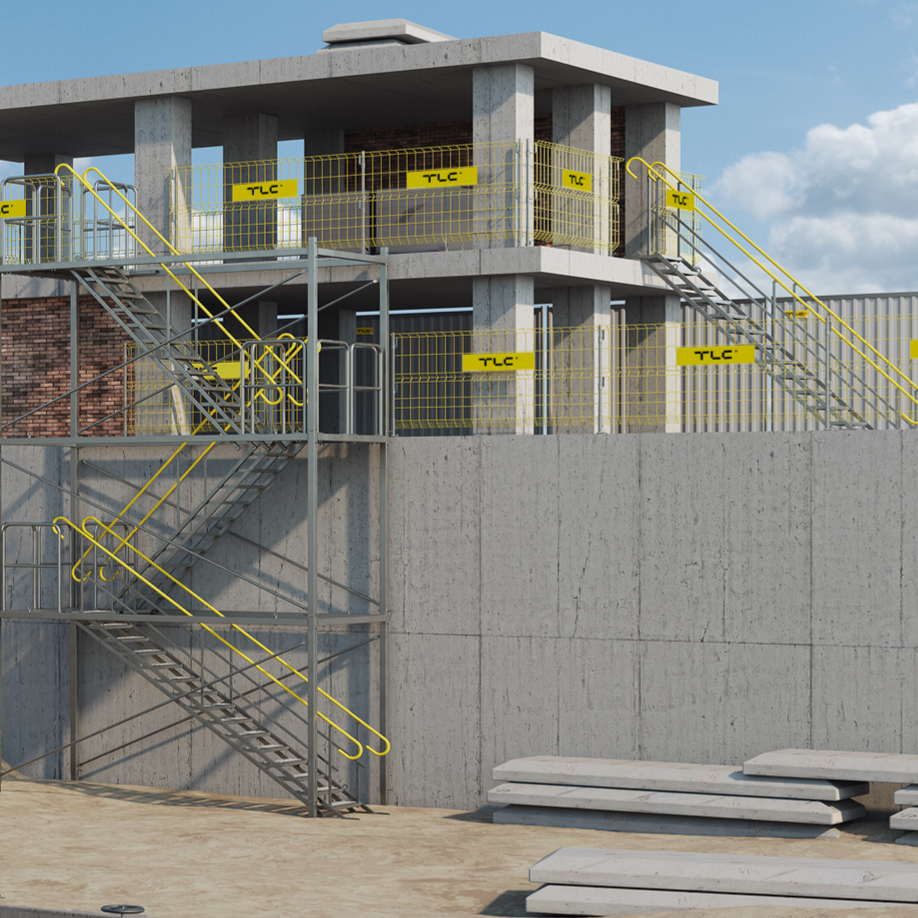

The TAS (Temporary Access System) system is an exceptionally flexible solution for temporary access on construction sites, standing out for its modular design, durability, and safety. TAS temporary staircases are a versatile tool that can be applied across a wide range of construction projects, from residential and commercial buildings to large-scale industrial and infrastructure ventures.

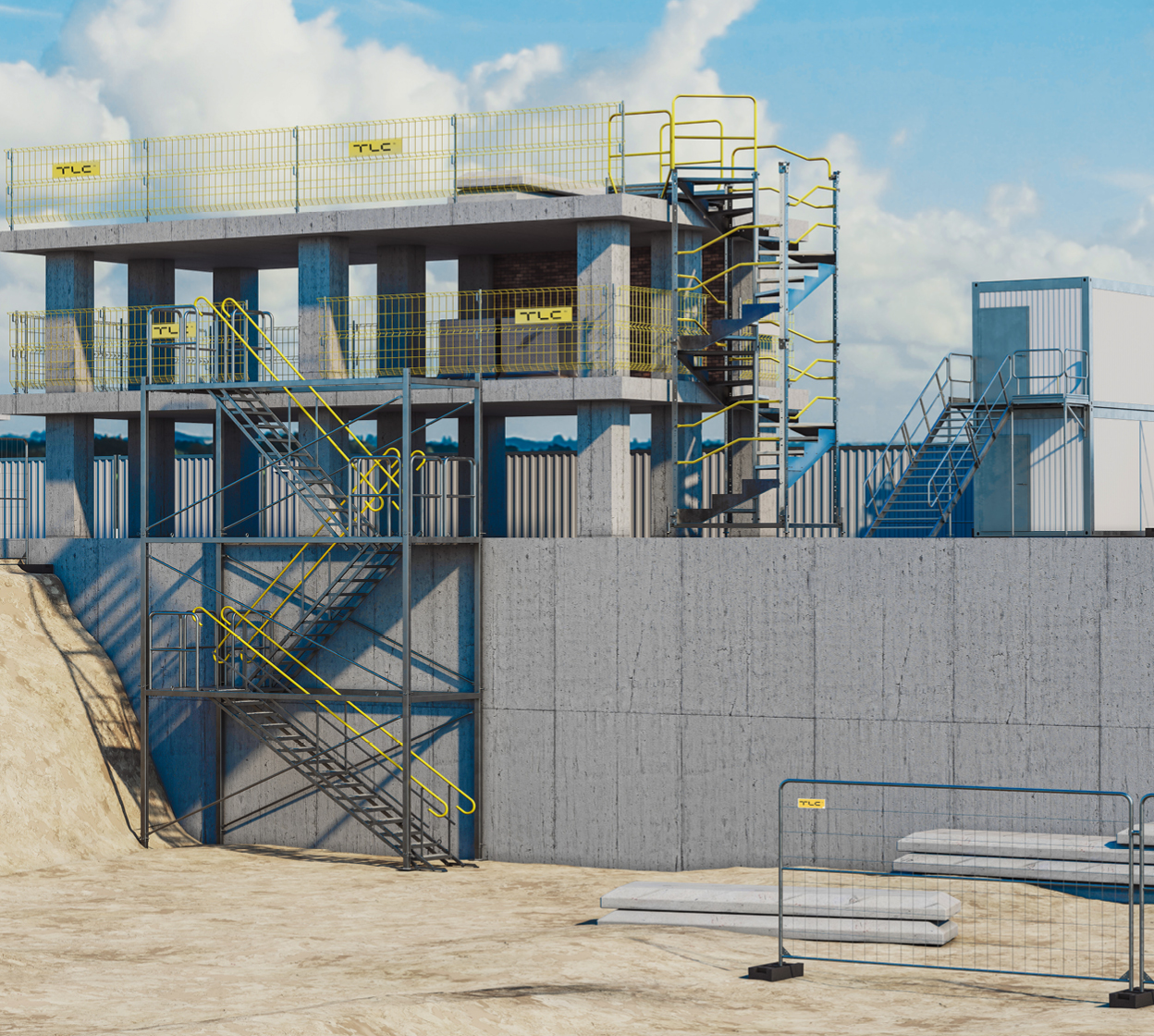

One of the primary advantages of the TAS system is its ease of installation and dismantling. Thanks to its modular design, the stairs can be assembled quickly without the need for specialized tools. This makes TAS stairs an ideal choice for rapidly changing construction environments where flexibility and speed are essential. Additionally, our solutions comply with the highest safety standards, making them the perfect choice for projects requiring temporary access to elevated levels.

Key features of TAS temporary staircase

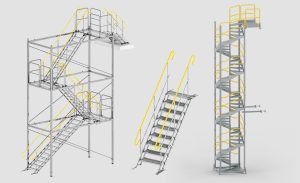

- Modular design: TAS staircases are designed with maximum flexibility in mind. The modular system allows easy adjustment to the specific needs of any project, enabling quick modifications to the staircase layout as required.

- Fast installation and dismantling: With a simple and intuitive design, TAS staircases can be quickly assembled and dismantled, minimizing downtime on construction sites and allowing for smooth project execution.

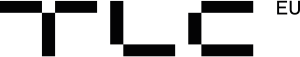

- Weather resistance: Made from galvanized steel, TAS stairs are corrosion-resistant and durable in extreme weather conditions, making them the perfect outdoor solution regardless of the environment.

- High safety standards: TAS staircases meet all safety requirements, ensuring secure work even at high elevations. Additionally, they are equipped with anti-slip steps and protective railings, providing stability during use.

- Time and cost efficiency: Thanks to their simple construction and rapid installation, TAS staircases help save both time and money, which is particularly important in projects requiring frequent layout changes.

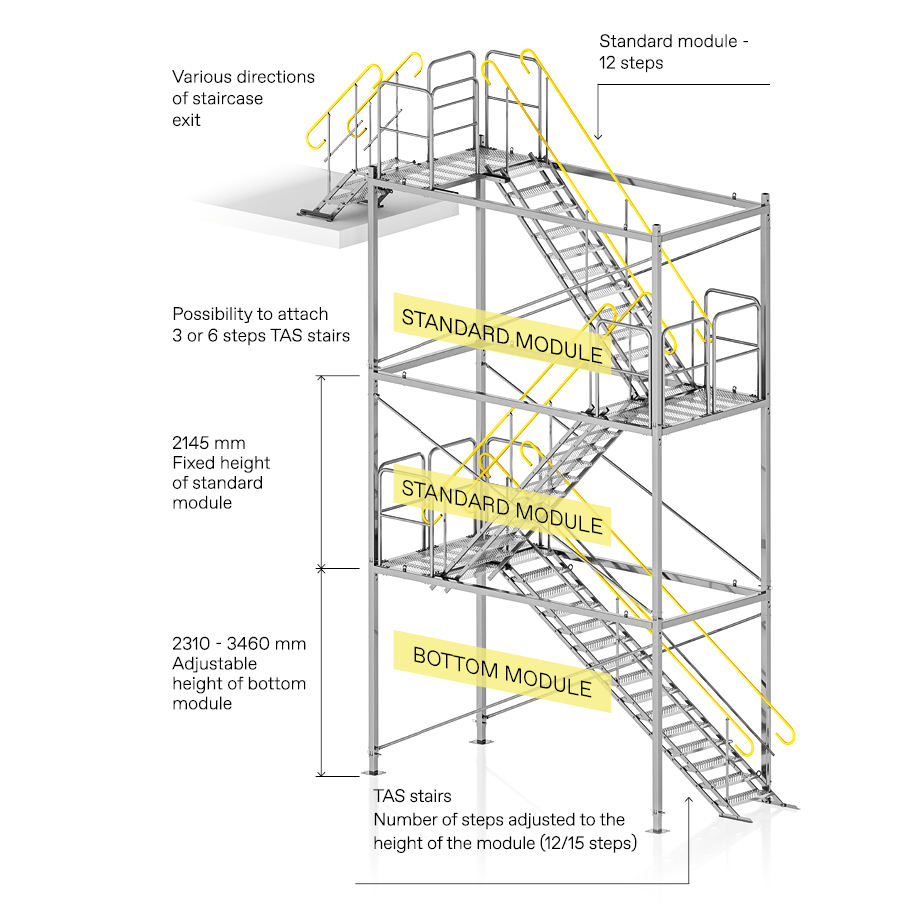

The TAS staircase descent is specifically engineered to bridge level differences and eliminate the gap between the staircase and the desired platform or ground level, ensuring smooth and secure access for users. This is especially important in environments where precision in height alignment is crucial to maintaining safe and efficient operations.

The staircase offers a versatile height adjustment feature, allowing it to be set at 7 different positions, each incrementing by 195 mm. This flexibility ensures that the staircase can adapt to varying height requirements, making it a practical solution for diverse construction or industrial applications.

To further refine the height adjustment and perfectly align the staircase with the target level, additional TAS steps (available in sets of 3 or 6 steps) can be attached using a special adapter. This system enables seamless integration between the existing staircase and the extra steps, allowing for smooth, continuous access at the desired exit point. By using these extra steps, we can fine-tune the height, eliminating any remaining level differences or gaps, and ensuring that the staircase exit is fully aligned with the required elevation. This adaptability provides a high level of functionality and convenience, particularly on sites where variable height adjustments are frequently needed.

The TAS staircase system is a versatile, temporary structure designed for safe and efficient access between levels on construction sites. The system is compliant with PN EN 12811-1: 2007, ensuring it meets high standards for safety and functionality. One of the standout features of this system is its modular design, which simplifies assembly and disassembly by minimizing the need for complex fasteners such as bolts and nuts.

The staircase components include stairs, platforms, railings, posts, and brackets, all designed for easy installation. The permissible distributed load for platforms and stairs is 1.0 kN/m², making the system sturdy enough for most industrial applications. With a usable width of 700 mm, the stairs and platforms are spacious enough to accommodate workers and tools safely. The system is made from high-strength steel (S235 / S355), with a hot-dip galvanized anti-corrosion coating, ensuring durability in even the harshest weather conditions.

Product materials

Technical Documentation

Certification

We ensure that all of our products are of the highest quality through compliance with Factory Manufacture Control certification with EN 1090-1:2009+A1:2011, issued by the TÜV SÜD Polska Sp. z o.o. Certification Centre.

We are a manufacturer with a certificate of the Integrated Quality, Environment and Health and Safety Management System according to ISO 9001/ ISO 14001/ ISO 45001 issued by Bureau Veritas Certification.

Our construction products meet the requirements of the European Directive 305/2011 (CPR) for structural steel and aluminum.

We have Environmental Product Declarations (EPDs) for our products. This is a global Type III declaration programme that follows the principles of ISO 14025. An EPD is a standardised document that provides information on the environmental impact of a product.

Integrated Management System Policy

Gorlice, 1.05.2023, 5th edition

Design, production of metal structures, powder coating, hot-dip galvanzing of steel structures

Bureau Veritas Certification, ISO 9001:2015; ISO 14001:2015; ISO 45001:2018

EPD Environmental Product Declaration

In accordance with ISO 14025:2006 and EN 15804:2012+A2:2019/AC:2021 for: STEEL STAIRS Steel straight/spiral stairs, container stairs P-SK3, 4, 5, 6, 7, 8, SK-KS, TAS and SST temporary stairs, ASTA, CARLA, LINEA modular stairs, industrial communication systems including ladders