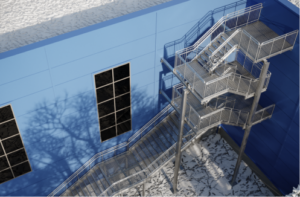

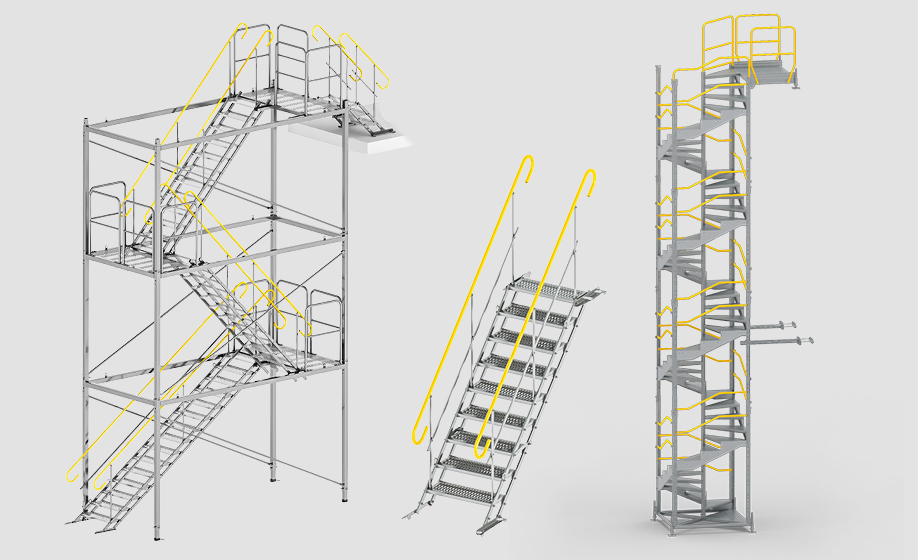

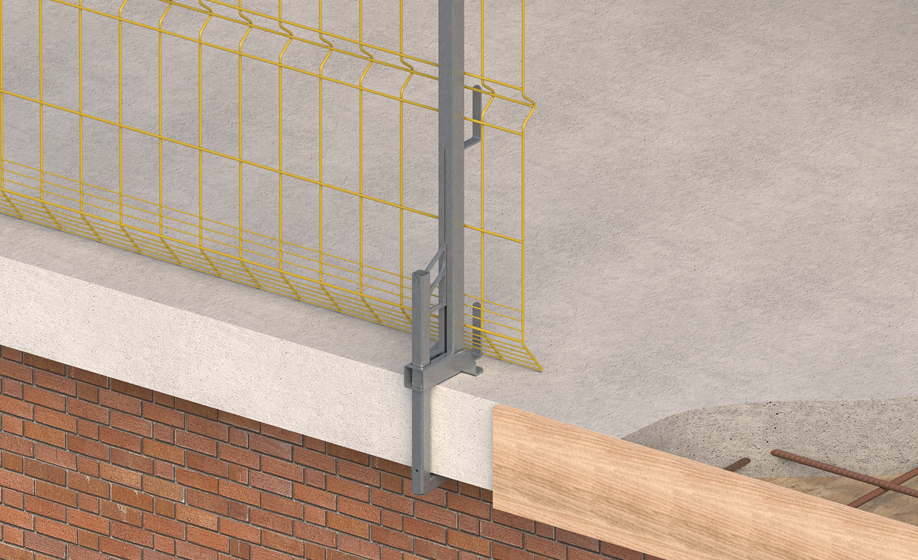

EPS edge protection system

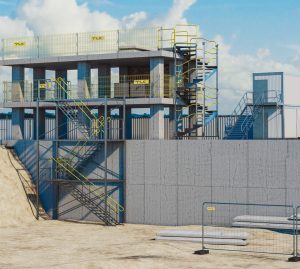

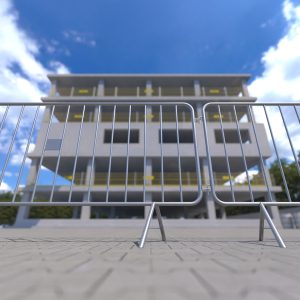

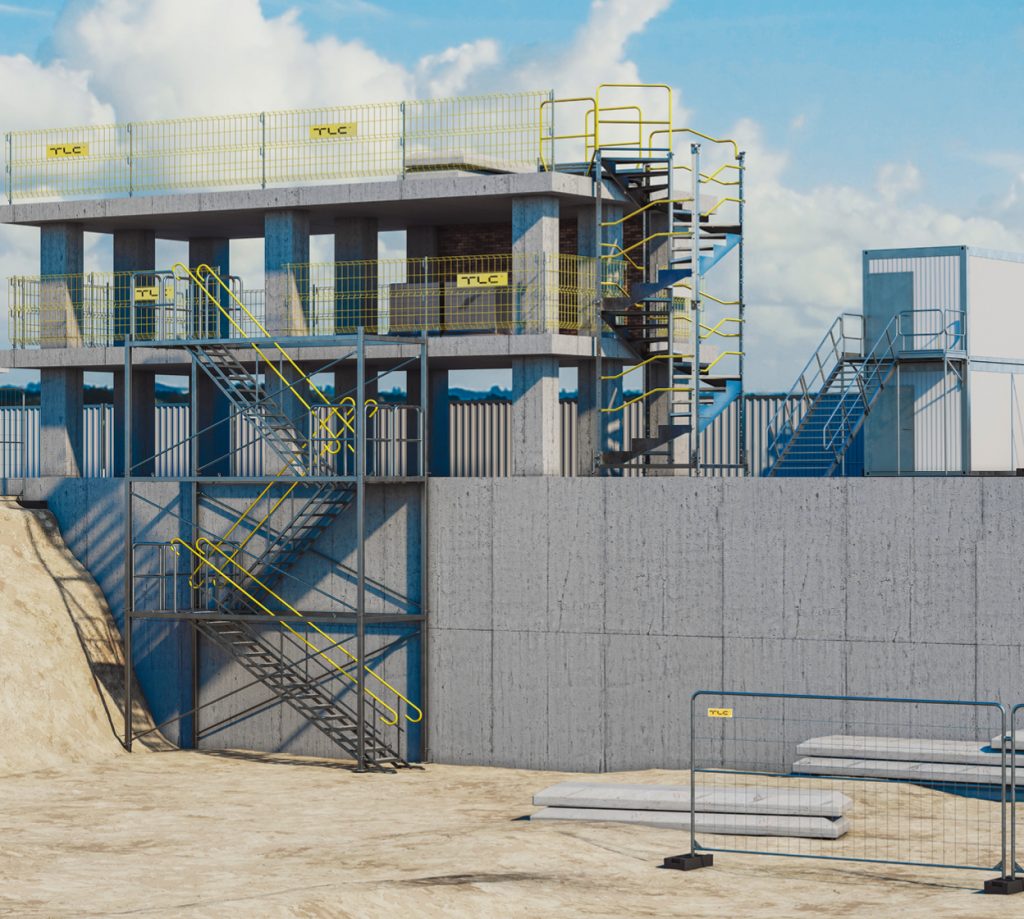

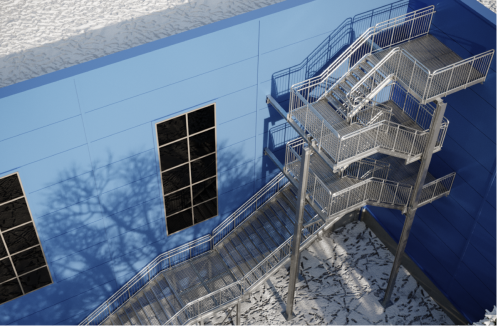

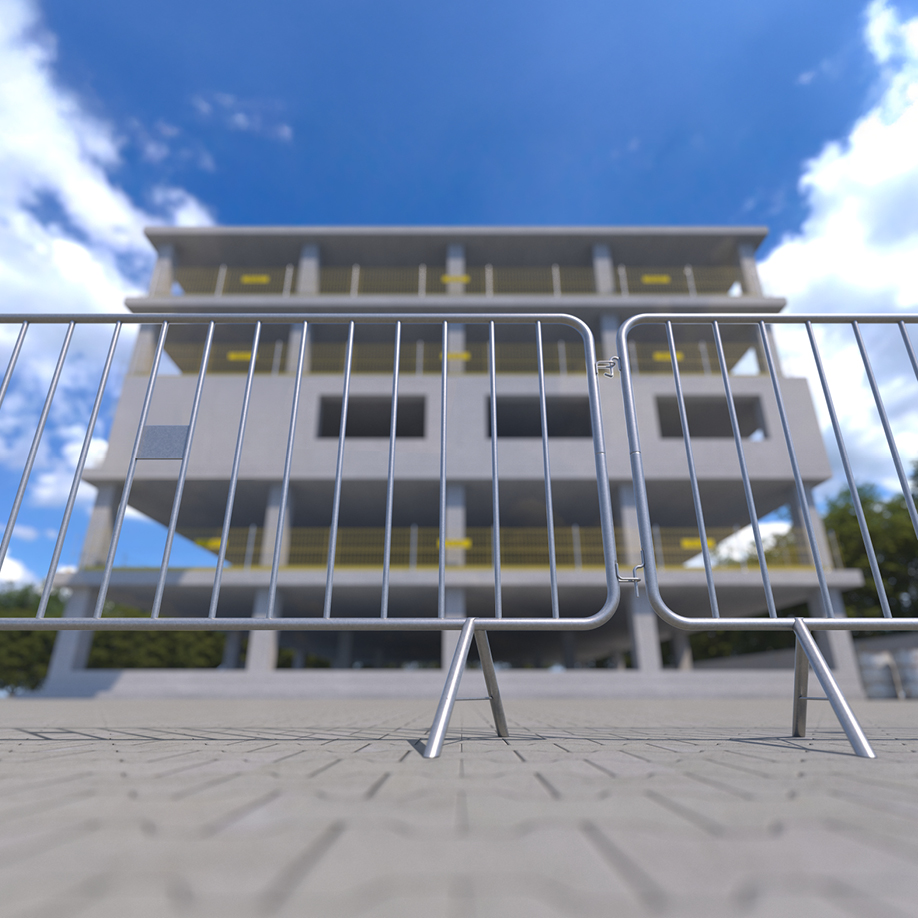

Our Edge Protection System is a modern fall protection system designed to secure building and construction edges, technological openings (elevators, etc.), roof edges, passageways and other areas where there is risk of falling from height.

Meeting all European safety standards, EPS ensures that any construction site meets all EU regulations, which can be rigorous in the industry. It does this by offering protection from falls, through its engineered edge fall prevention system.

Edge Protection System is a modern security system made in compliance with the class A EN 13374:2013-08 standard, dedicated to secure building and construction site edges, technological openings, passaweways and other places where there is risk of falling from height.

Caractéristiques standard des solutions disponibles

- Des solutions simples, bien pensées et testées qui garantissent la fiabilité et le plus haut niveau de sécurité possible

- Une protection anticorrosion robuste pour assurer la durabilité à long terme de tous les éléments, même s’ils sont exploités

- L’assemblage des éléments du système ne nécessite pas de personnel hautement qualifié

- Large offre de supports et de fixations

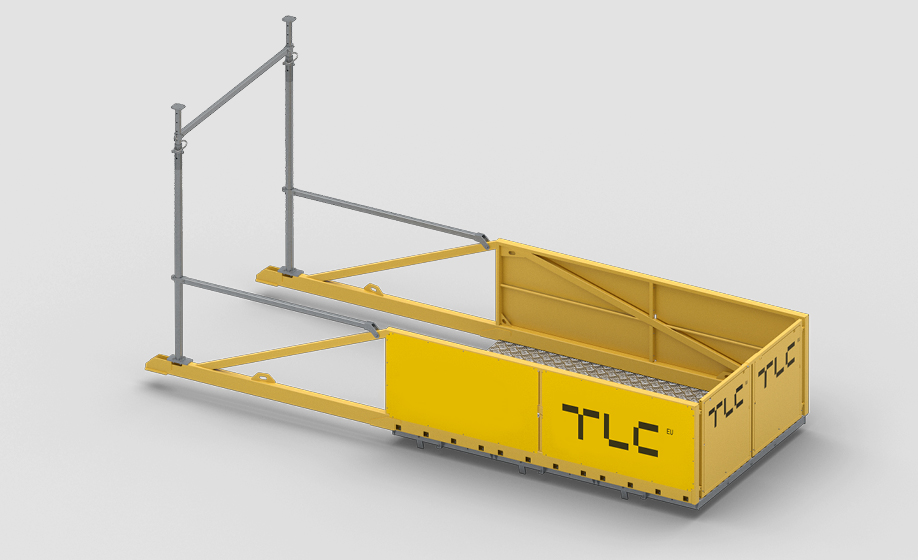

- Des paniers de transport spéciaux facilitent le chargement, le déchargement, le transport et le stockage de tous les éléments

- Le produit a reçu un avis positif de l’Institut de la construction mécanisée et de l’exploitation des roches (Mechanised Construction and Rock Mining Institute) pour sa conformité à la norme EN 13374:3013-08

Comment installer un système de protection des bords ?

Le choix et la sélection d’un système de protection des bords doivent être adaptés aux besoins et aux conditions du chantier. Les facteurs de base à prendre en compte lors de l’installation d’un tel système sont la fréquence des travaux sur un chantier donné et le matériau/sol sur lequel le système sera installé.

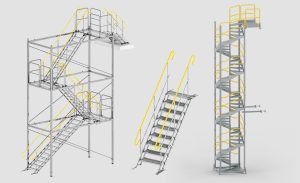

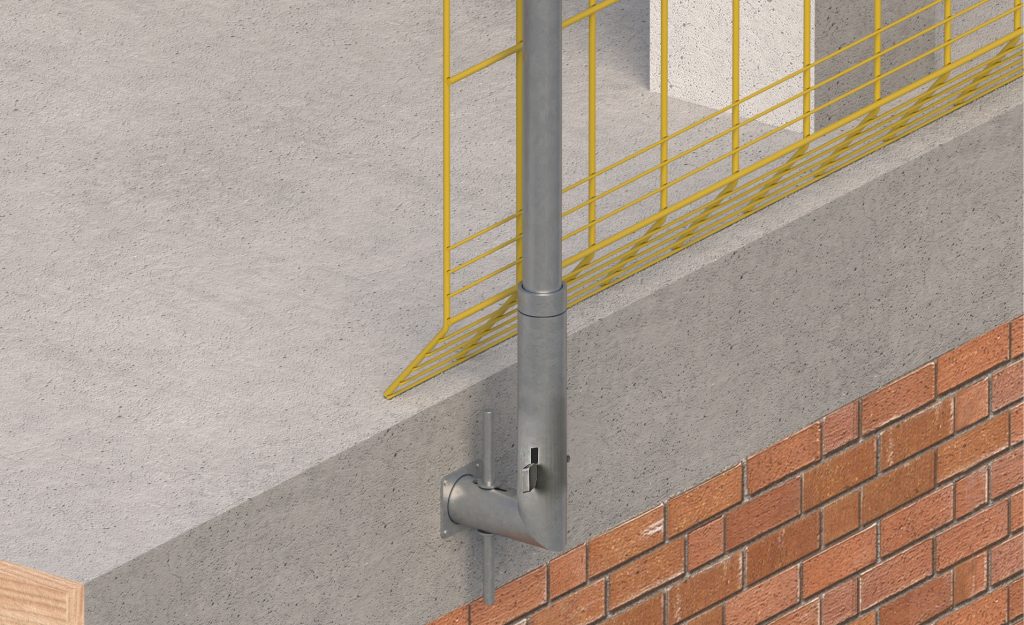

Les composants de base du système sont les poteaux universels et les supports de montage. Les poteaux sont compatibles avec tous les supports de montage, tandis que la grande variété de ces supports permet d’utiliser le système à chaque étape des travaux de construction. Vous trouverez des informations détaillées sur la manière d’installer correctement les supports dans le catalogue disponible dans l’onglet Système EPS. De plus, nos employés expérimentés se feront un plaisir de vous fournir des informations supplémentaires et de configurer le système en fonction de vos besoins individuels.

- Construction boulonnée efficace

La plateforme est conçue pour être boulonnée à partir de composants individuels, ce qui facilite la manipulation pendant la logistique, le montage et le démontage. Cette conception modulaire contribue également à réduire les coûts de transport, car elle peut être emballée de manière compacte et facilement déplacée vers et depuis les chantiers. - Protection anticorrosion

Pour une durabilité à long terme, nos plateformes sont revêtues d’une protection anticorrosion par galvanisation à chaud, selon la norme PN-EN ISO 1461, ou d’un thermolaquage pour une finition protectrice et esthétique. - Option de couverture publicitaire personnalisable

En plus d’être fonctionnelles, nos plateformes peuvent également servir d’outil de marque. Nous offrons la possibilité d’apposer une couverture publicitaire avec n’importe quel design ou surimpression personnalisé, ce qui permet à votre entreprise de se démarquer tout en garantissant la sécurité sur le chantier.

Product materials

Certification

We ensure that all of our products are of the highest quality through compliance with Factory Manufacture Control certification with EN 1090-1:2009+A1:2011, issued by the TÜV SÜD Polska Sp. z o.o. Certification Centre.

We are a manufacturer with a certificate of the Integrated Quality, Environment and Health and Safety Management System according to ISO 9001/ ISO 14001/ ISO 45001 issued by Bureau Veritas Certification.

Our construction products meet the requirements of the European Directive 305/2011 (CPR) for structural steel and aluminum.

Integrated Management System Policy

Gorlice, 1.05.2023, 5th edition

Design, production of metal structures, powder coating, hot-dip galvanzing of steel structures

Bureau Veritas Certification, ISO 9001:2015; ISO 14001:2015; ISO 45001:2018

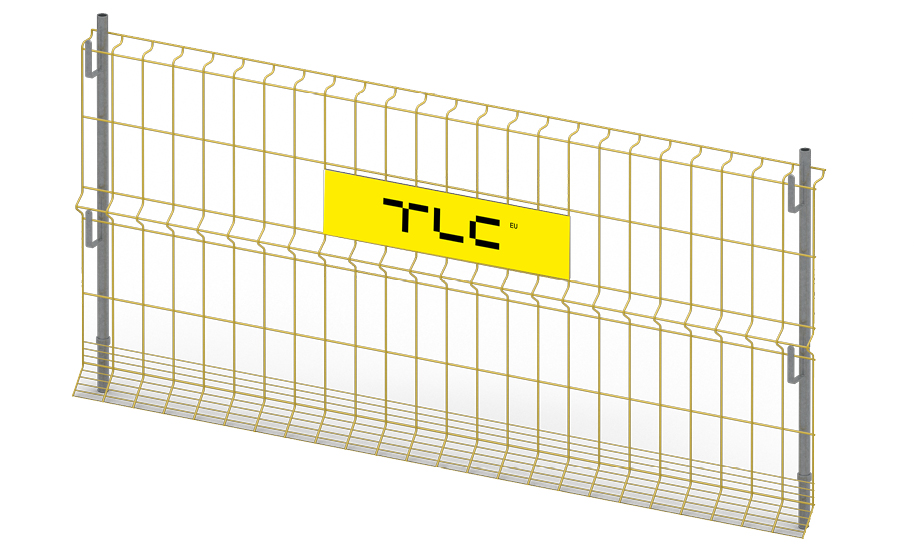

Panels

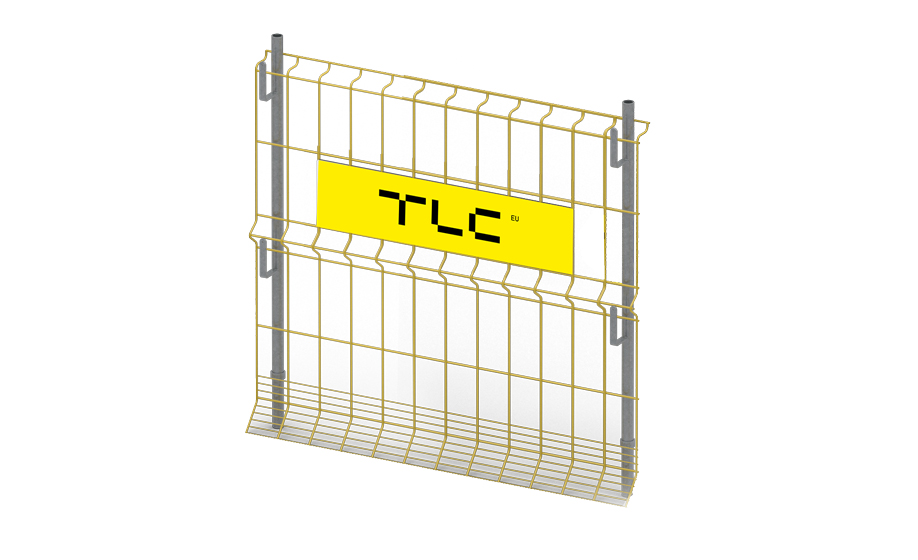

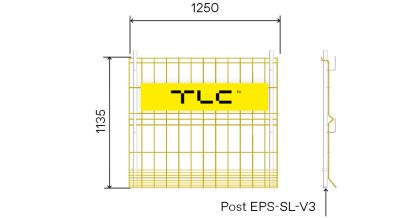

EPS Mesh ECO panel EPS-PAN-ECO3

| Application: Protecting the working edge against falling people, tools or construction materials. |

| Weight: 12 kg |

| Wire diameter: 3 mm (bottom fold), 6 mm |

| Index: EPS-PAN-ECO3 |

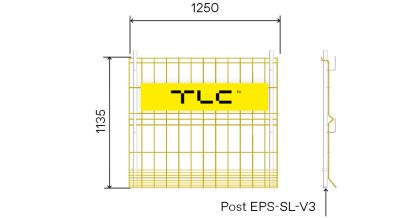

EPS Mesh ECO panel - half EPS-PAN-ECO3-H

| Application: Securing the working edge against falling people. |

| Weight: 6,2 kg |

| Wire diameter: 3 mm (bottom fold), 6 mm |

| Index: EPS-PAN-ECO3-H |

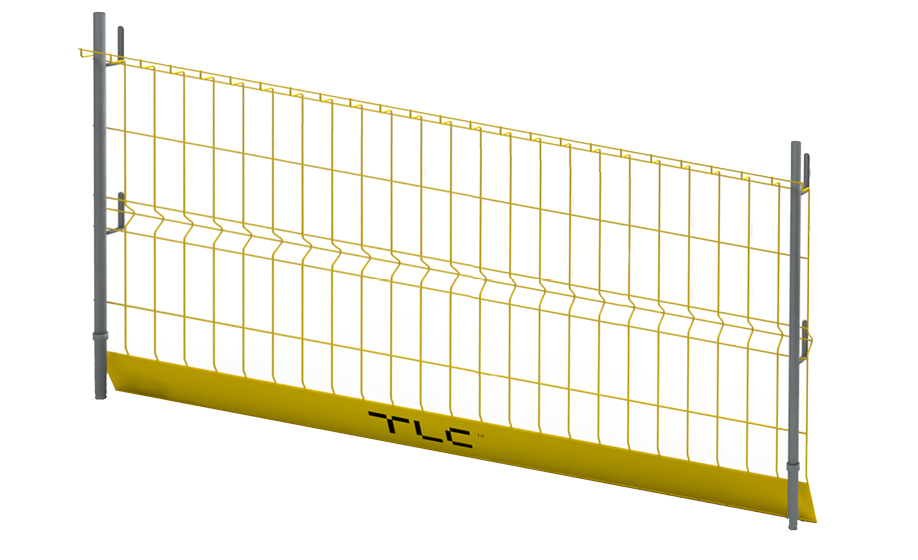

EPS Mesh panel with plank EPS-PAN-I

| Application: Secure the working edge against falling people, tools or construction materials. |

| Weight: 14,7 kg |

| Wire diameter: 6 mm |

| Index: EPS-PAN-I |

EPS Mesh panel with plank - half EPS-PAN-I-H

| Application: Securing the working edge against falling people. |

| Weight: 7,4 kg |

| Wire diameter: 6 mm |

| Index: EPS-PAN-I-H |

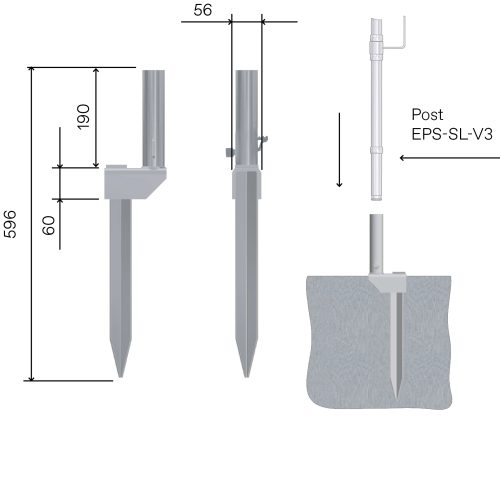

Timber planks EPS-D

| Application: Protecting the working edge against falling people. |

| Weight: 6,5 kg |

| Plank thickness: 32 mm |

| Index: EPS-D |

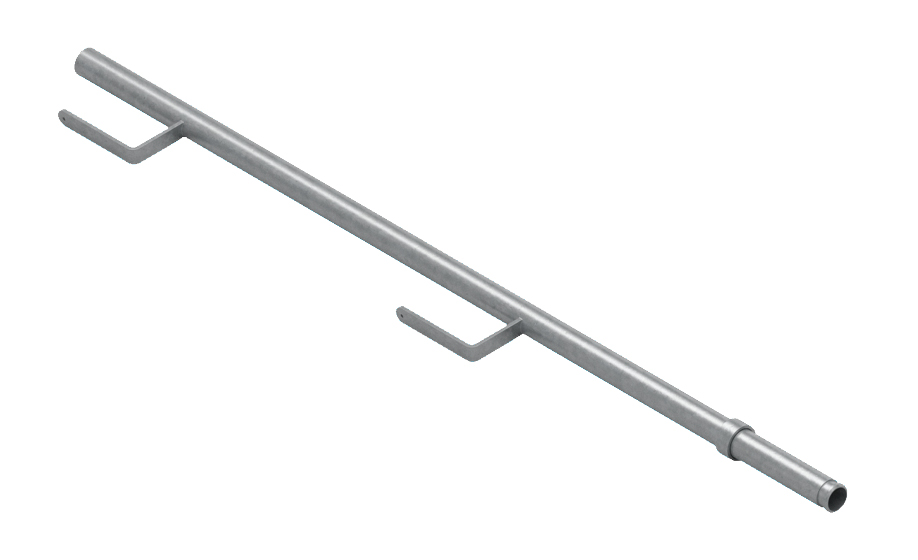

Scaffolding tube

| Application: Protecting the working edge against falling people. |

| Assembly: Adjust the element length and assemble it on system pole hooks. |

| Version 500 mm: Regulation range (L) 500 – 700 mm Weight: 1,9 kg Index: EPS-R500 |

| Version 700 mm: Regulation range (L) 700 – 1050 mm Weight: 2,8 kg Index: EPS-R700 |

| Version 1050 mm: Regulation range (L) 1050 – 1750 mm Weight: 5,3 kg Index: EPS-R1050 |

| Version 1750 mm: Regulation range (L) 1750 – 3000 mm Weight: 8,9 kg Index: EPS-R1750 |

Holders and post

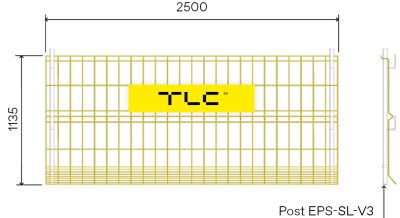

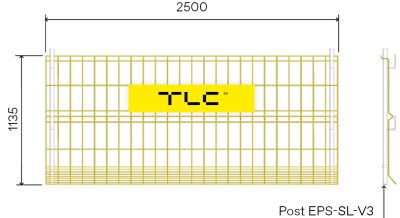

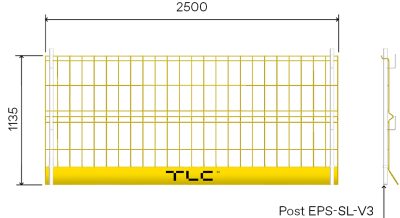

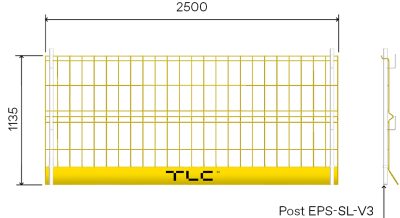

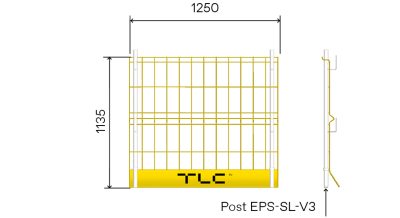

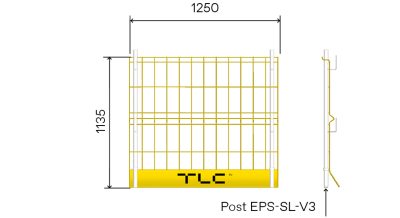

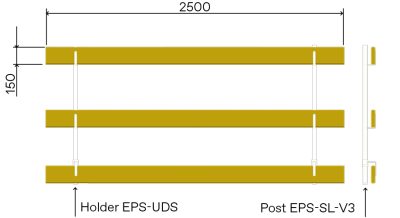

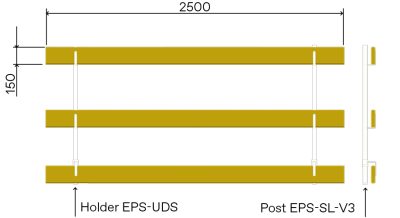

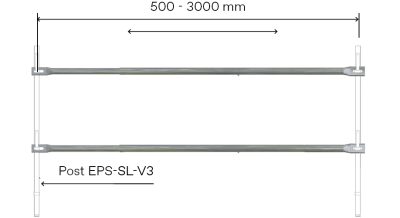

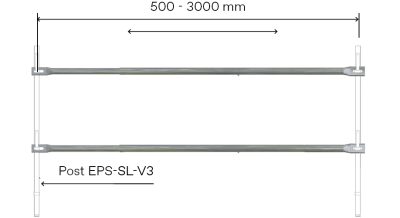

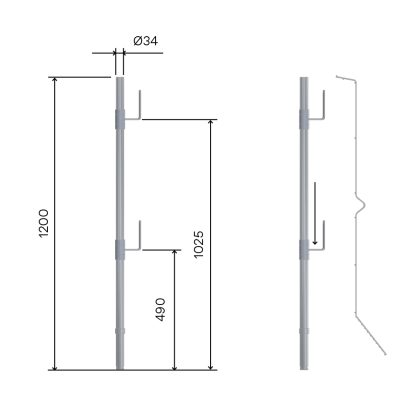

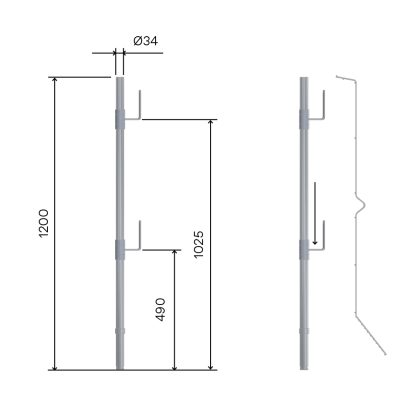

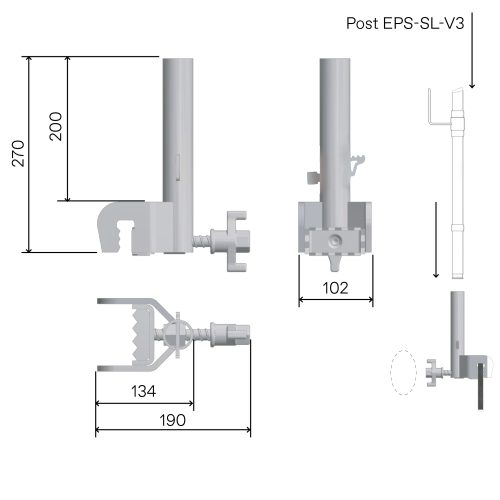

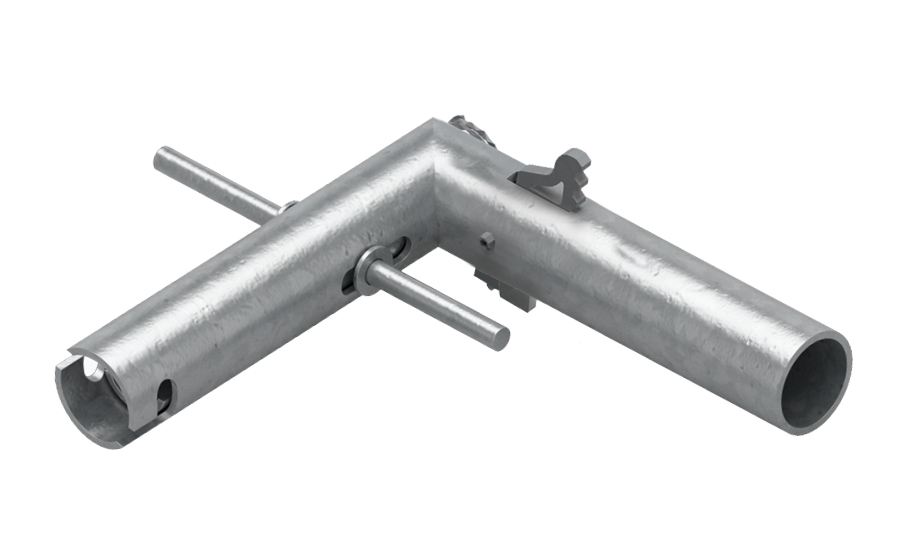

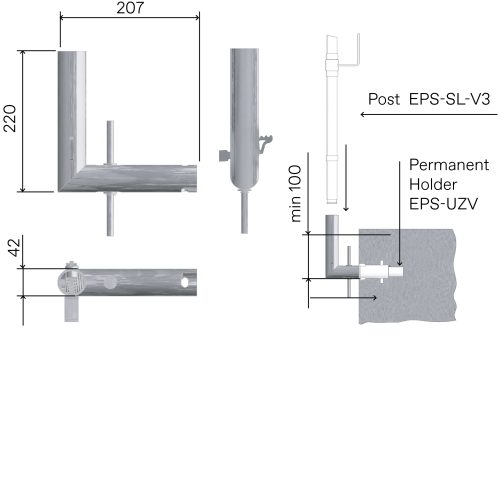

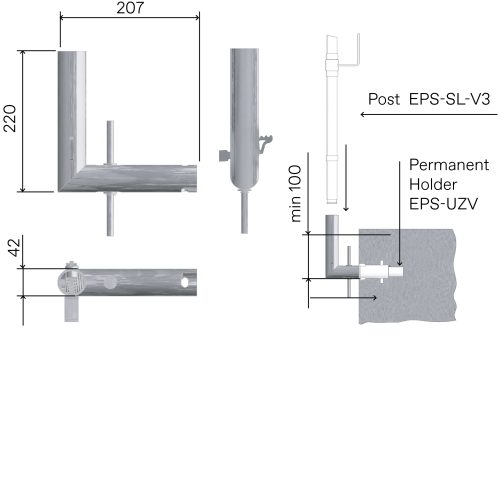

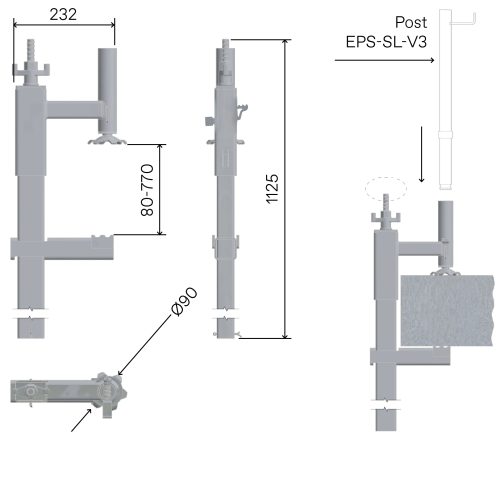

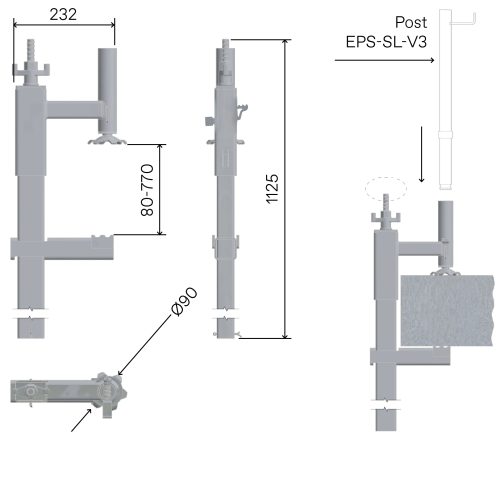

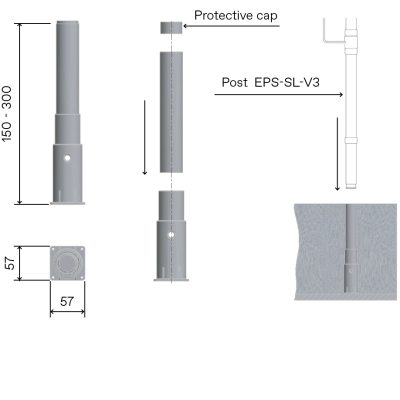

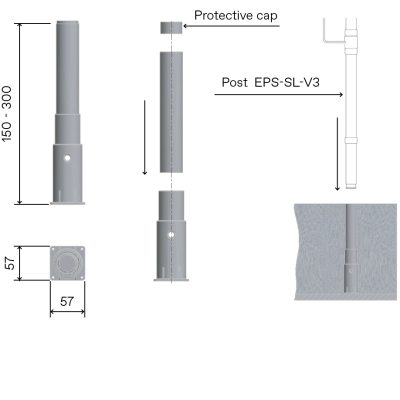

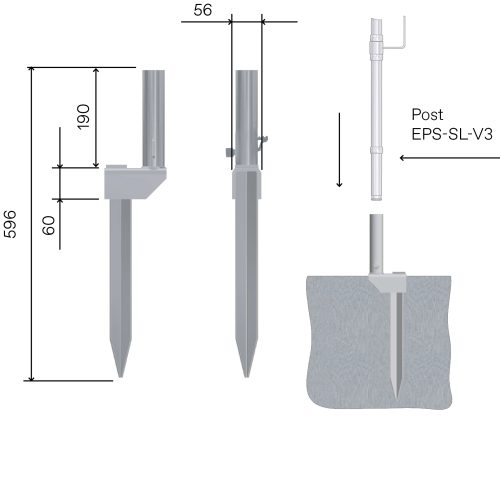

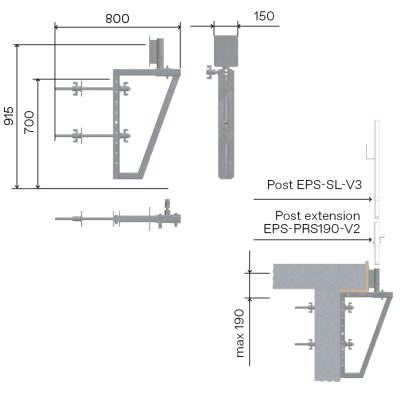

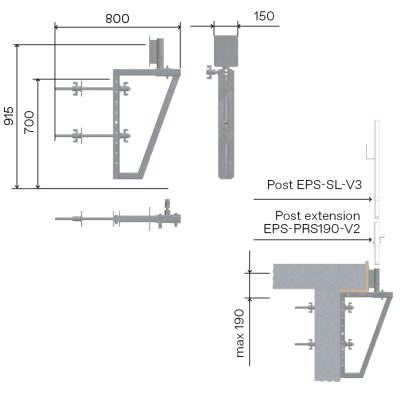

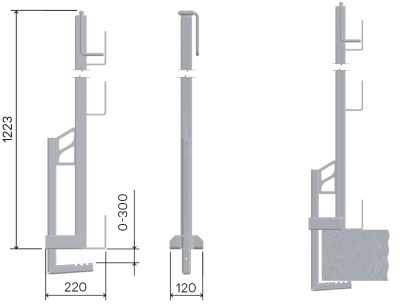

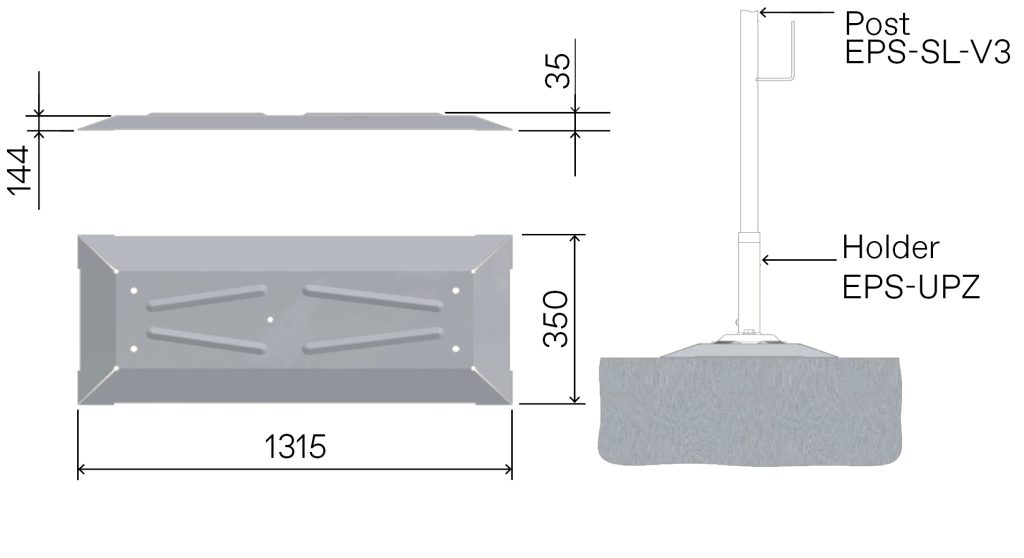

System post EPS-SL-V3

| Application: Assembling all EPS panel types (mesh panels, planks and scaffolding tubes). |

| Assembly: Embed the post in the socket of a holder equipped with a bolt - the latchlock will secure the post automatically. Disassemble by pressing the holder’s detent. |

| Weight: 3,7 kg |

| Index: EPS-SL-V2 |

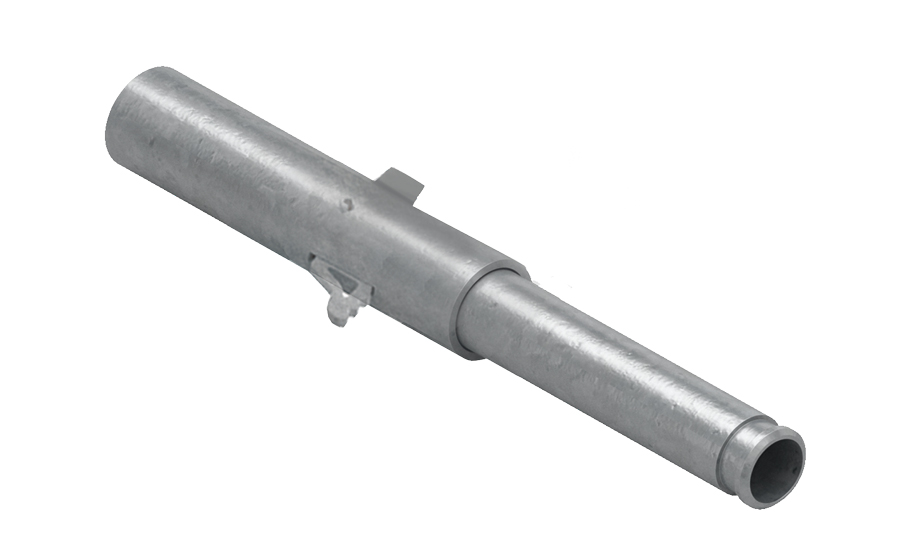

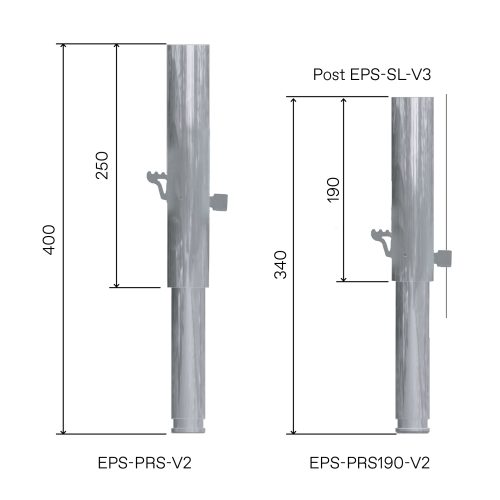

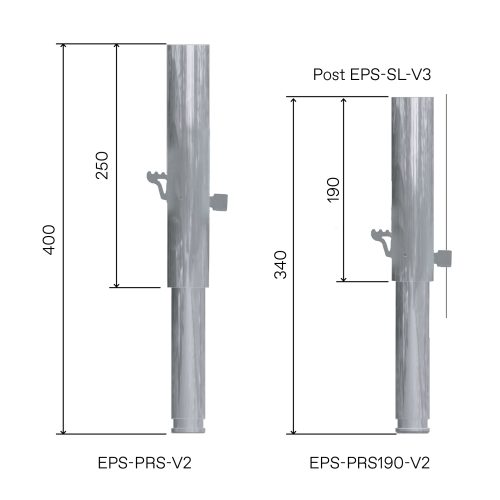

Post extension EPS-PRS

| Application: Extending the universal pole to obtain proper protection height when using e.g. girder, structural, clamping or permanent holders. |

| Assembly: Assembly and disassembly of the extension is conducted in the same manner as system posts. |

| Weight: 1,4 kg (250 mm version) / 1,1 kg (190 mm version) |

| Index: EPS-PRS-V2 / EPS-PRS190-V2 |

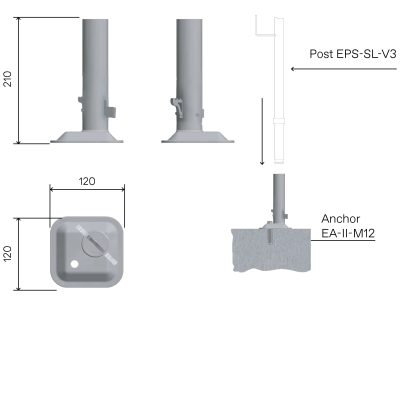

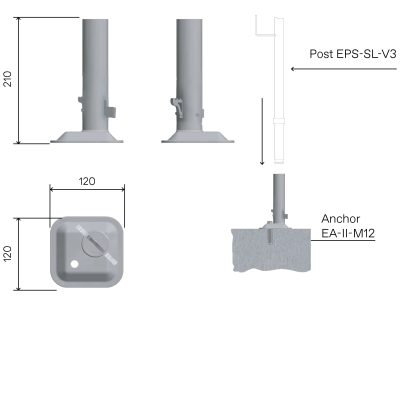

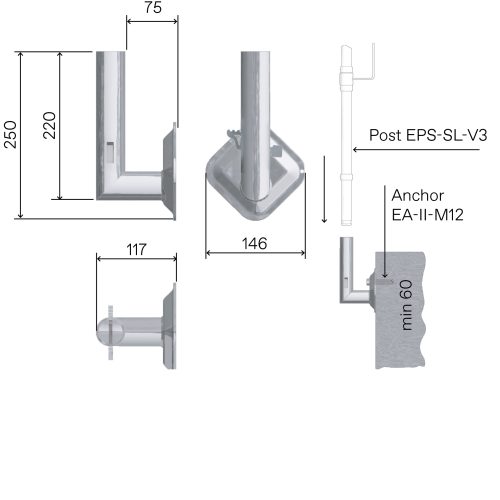

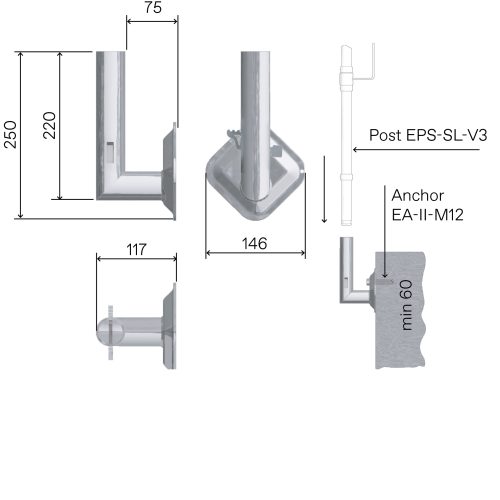

Horizontal screw-fastened holder EPS-UPZ-V2

| Application: Assembling the guardrail post on horizontal working surfaces, e.g. building ceiling. |

| Assembly: Screw the holder to the previously embedded anchor with internal thread M12 – the recommended anchor for the assembly is Fischer – EA II M12. During the anchor assembly, one should follow manufacturer’s instructions. |

| Weight: 1,3 kg |

| Index: EPS-UPZ-V2 |

Vertical screw-fastened holder EPS-UPN-V2

| Application: Assembling the guardrail post on vertical surface when construction external brick walls. |

| Assembly: Assembling and disassembly of the extension proceeds as in the case of the horizonal screw-fastened holder. |

| Weight: 1,5 kg |

| Index: EPS-UPN-V2 |

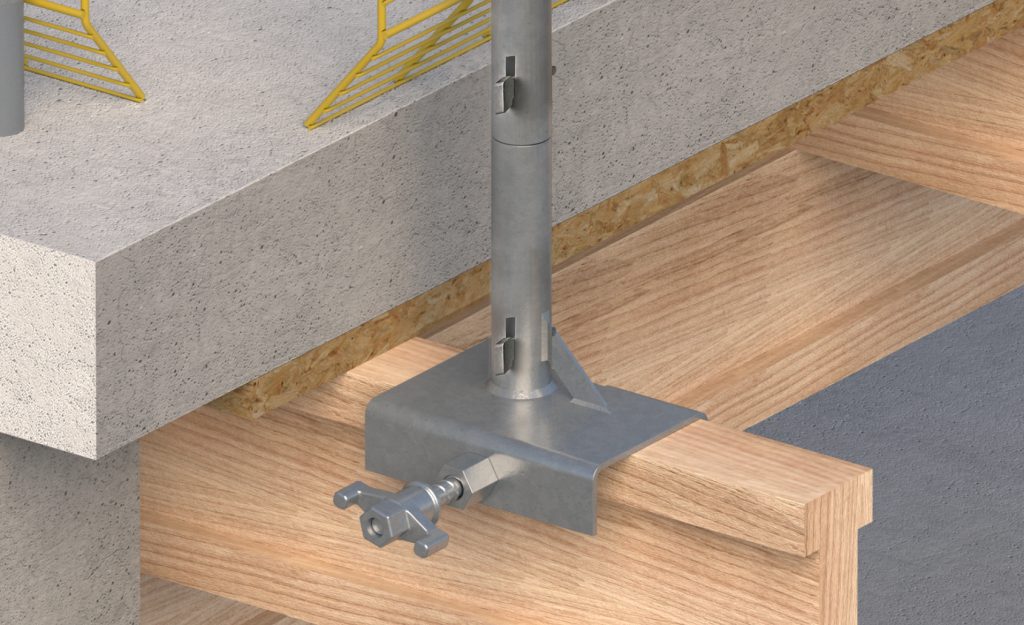

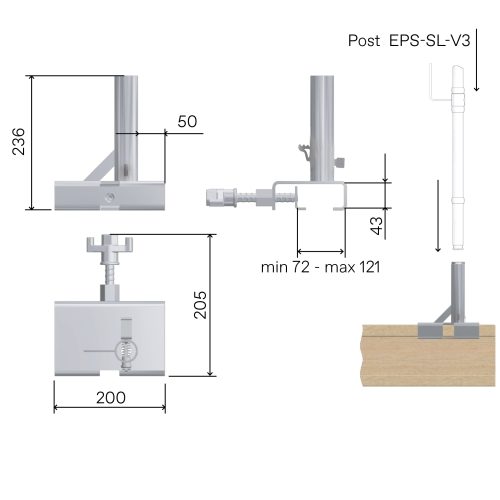

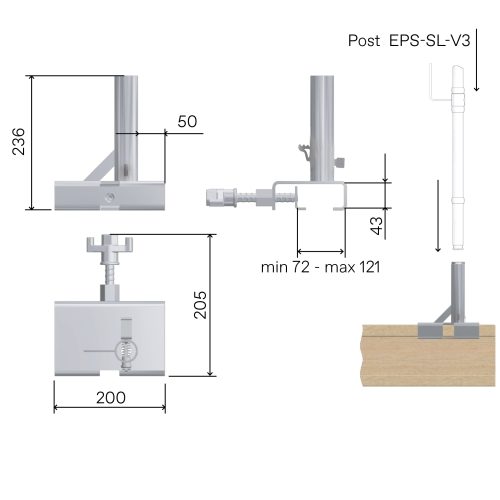

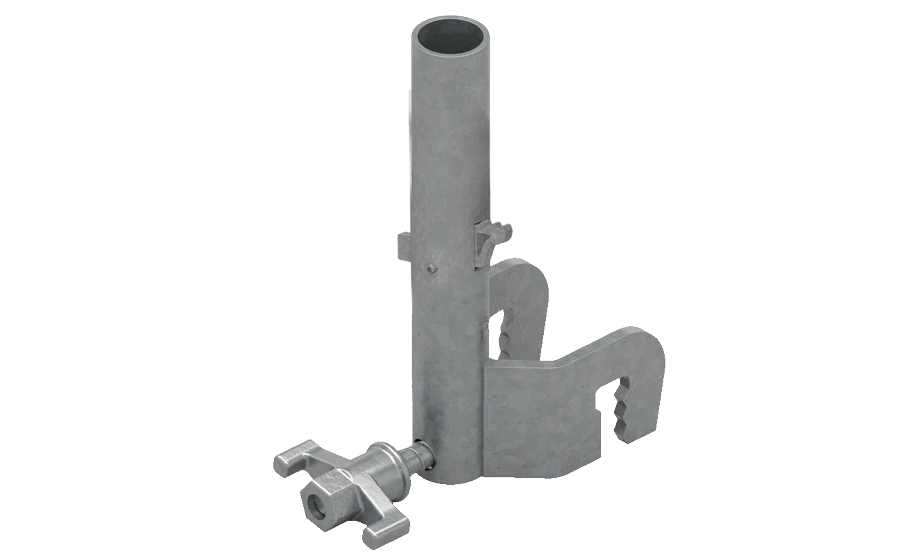

Girder holder EPS-UDZ-V2

| Application: Assembling the guaidrail post on girders or wooden beams. |

| Assembly: Slide the holder on the girder or beam, then tighten the clamp of the holder. |

| Weight: 3,4 kg |

| Index: EPS-UDZ-V2 |

Holder for steel structure EPS-UG-V2

| Application: Assembling the guardialipost onverticalsteelstructures like sheet piles sheet metals. |

| Assembly: Put the holder on a vertical element of the structure which maximum thickness is 16 mm, then tighten the clamp of the holder. |

| Weight: 2,6 kg |

| Index: EPS-UG-V2 |

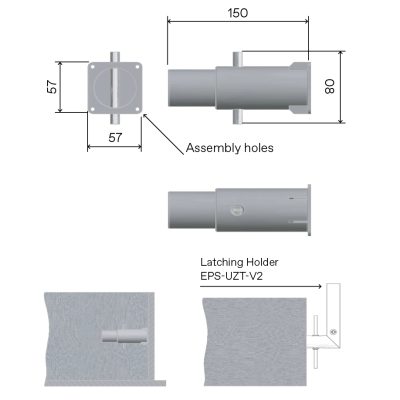

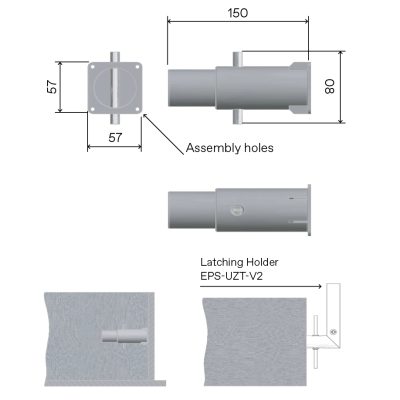

Latching holder EPS-UZT-V2

| Application: Assembling the guardrail post on vertical surfaces to previously prepared permanent vertical elements. |

| Assembly: Insert the holder at a proper angle- into the previousty prepored vertical permanent holder until you feel significant resistance. Turn the holder to the vertical position – the holder wilt clamp. To disassemble the element pull and turn the vertical bar, then remove the element from the opening. |

| Weight: 1,7 kg |

| Index: EPS-UZT-V2 |

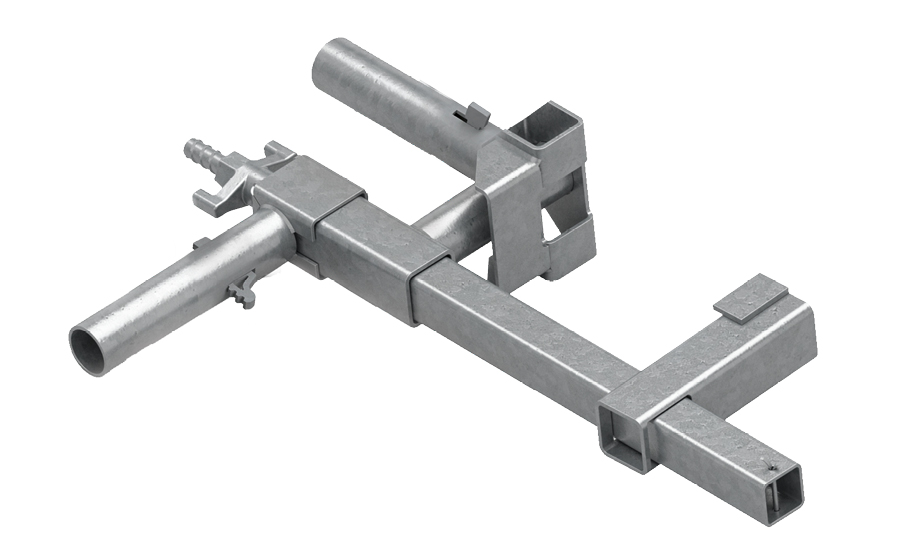

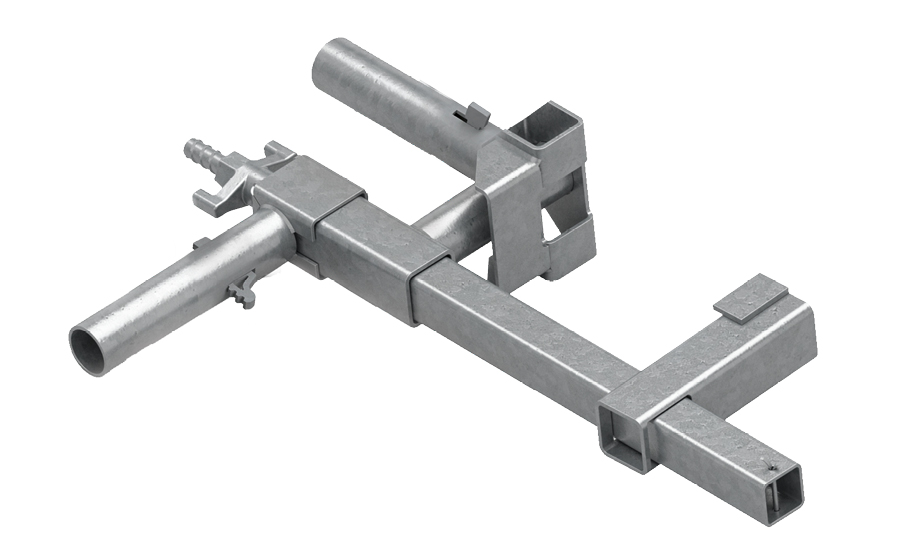

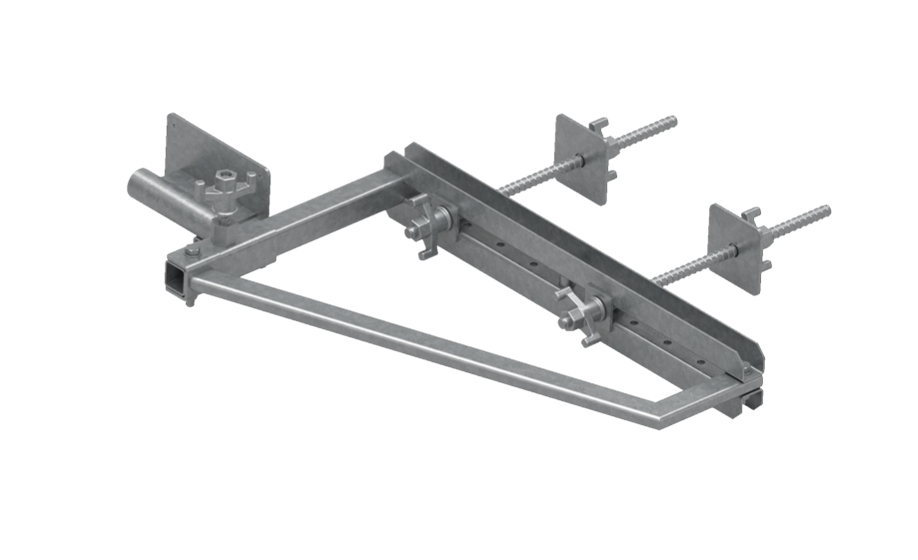

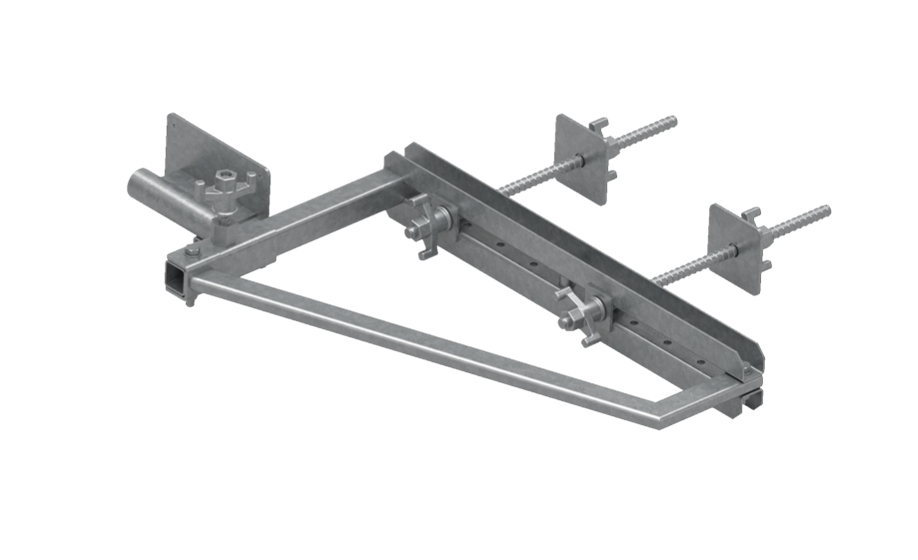

Clamping holder L800 EPS-UUN800-V2 / L500 EPS-UUN-V2

| Application: Assembling the guardrail post by clamping on horizontal surfaces. e.g. ceilings. concrete beams. staircases. |

| Assembly: Loosen the clamp thread. adjust the lower element to a desired height so that after adjusting the element. it will still have circa. 20mm regulation range available on the pressing element. Make sure that the holder base and the dish are property aligned in relation to the panel, then tighten the nut of the holder. |

| Weight: 8,5 kg / 5,5 kg |

| Index: EPS-UUN800-V2 / EPS-UUN-V2 |

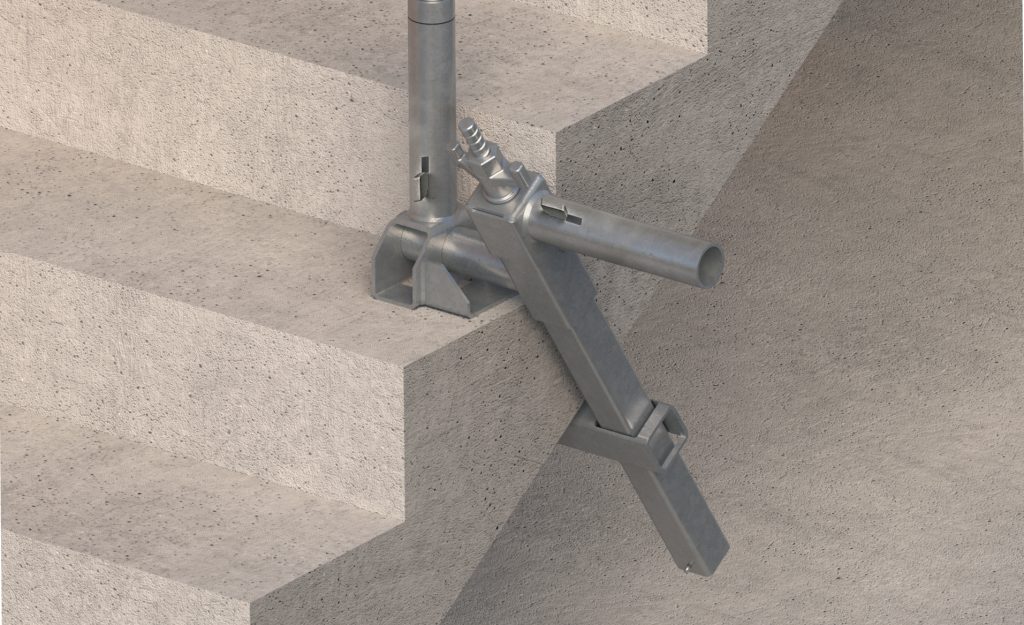

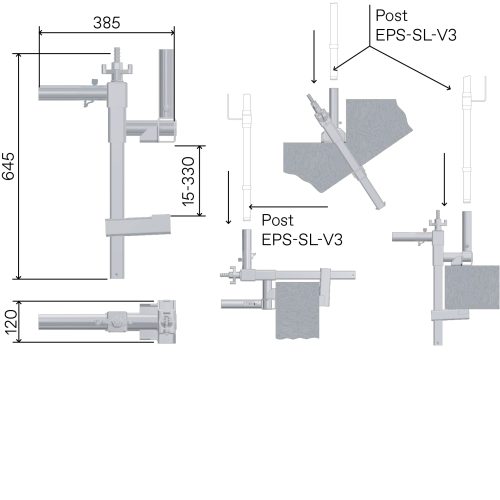

Stair holder EPS-UUN-V4

| Application: Assembling the guardrail post by clamping on vertical and horizontal surfaces, e.g., ceilings, concrete beams, staircases, walls. The clamp allows for assembly on a stairs flight. |

| Assembly: Adjust the holder to a dedicated assembly type (ceiling, wall, stairs). Loosen the clamp thread and adjust the lower adjustable element to the desired height. There should be 20 mm of regulation left on the pressing element. Tighten the nut of the holder. |

| Weight: 7 kg |

| Index: EPS-UUN-V4 |

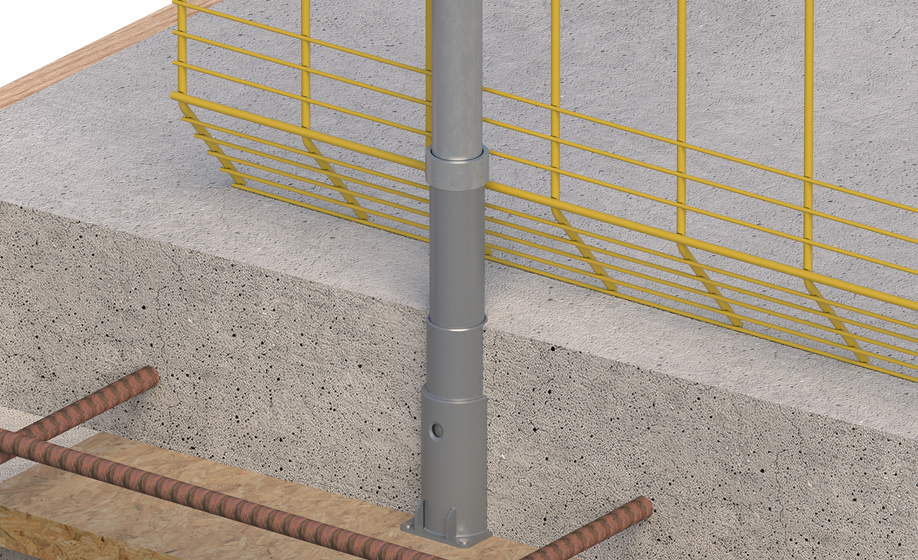

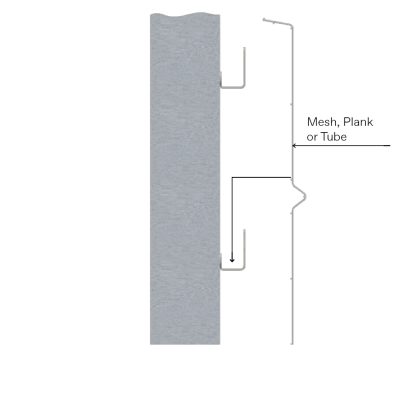

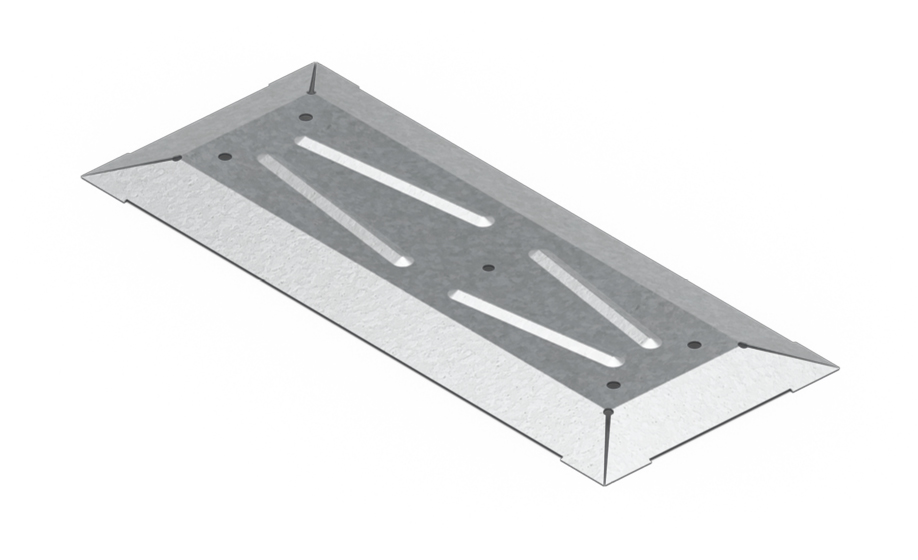

Horizontal permanent holder EPS-UZH-V2

| Application: Preparing the fastening socket for the system post. |

| Assembly: Nail the flange of the element to the formwork horizontal surface, put in the tube, which length was previously adjusted to the thickness of the ceiling, and protect It with a cap. The holder Is embedded to the formwork before concreting the structure, e.g. to the board, downstand beam or beams on horizontal surfaces. |

| Weight: 0,1 kg |

| Index: EPS-UZH-V2 |

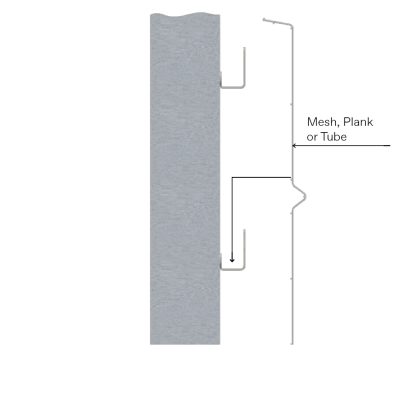

Vertical permanent holder EPS-UZV-V2

| Application: Preparing the fastening socket for the clamping holder EPS-UZT-V2. |

| Assembly: Nail the hoLder to the clapboard using special openings in the flange and arranging it in such a way that the bar Is oriented vertically. The holder Is embedded within the reinforcement before concreting the structure,i.e. panel, binder, or beam on their vertical surfaces. |

| Weight: 0,2 kg |

| Index: EPS-UZV-V2 |

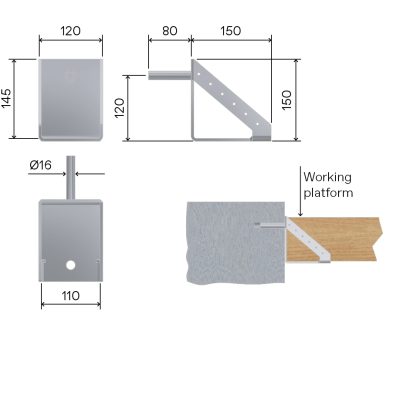

Drop in holder EPS-UW-V3

| Application: Assembling the guard rail post in the ground near the edge of ground excavations. |

| Assembly: Hammer into the ground to a depth of approximately 400 mm using a mallet EPS-UW-P and check stability of the holder. |

| Weight: 2,4 kg |

| Index: EPS-UW-V3 |

Plank lower holder EPS-UDS

| Application: Protecting the plank serving as a toe board. |

| Assembly: Put the holder on the system post or in sleeves of other holders. |

| Weight: 0,3 kg |

| Index: EPS-UDS |

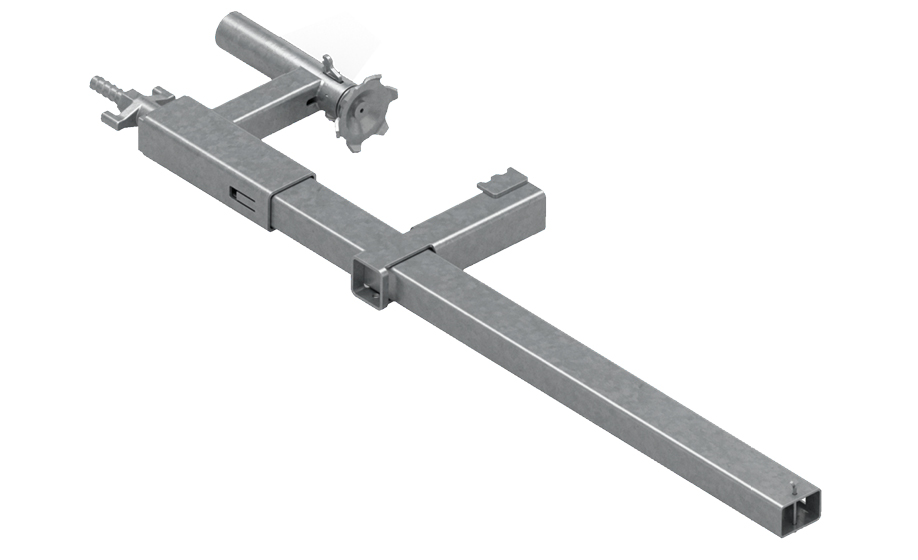

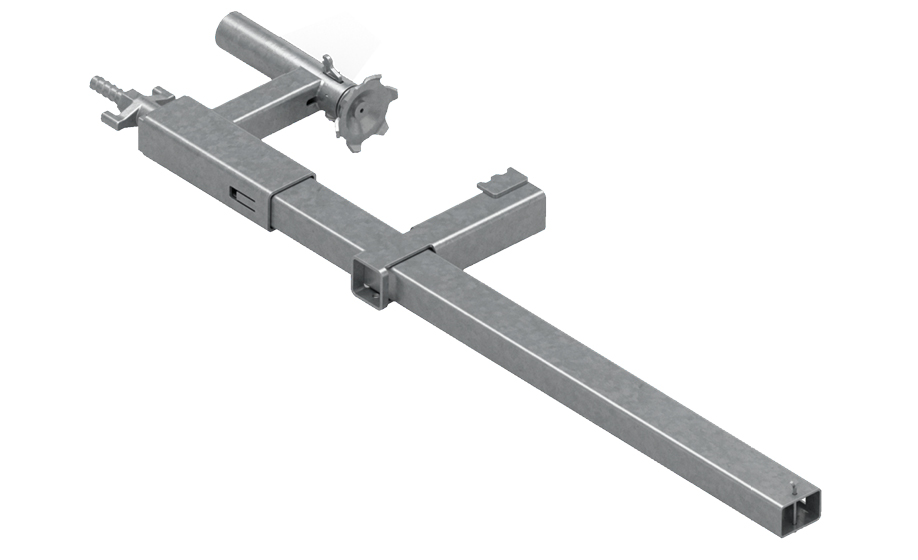

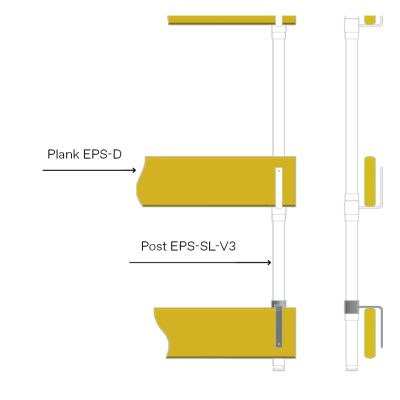

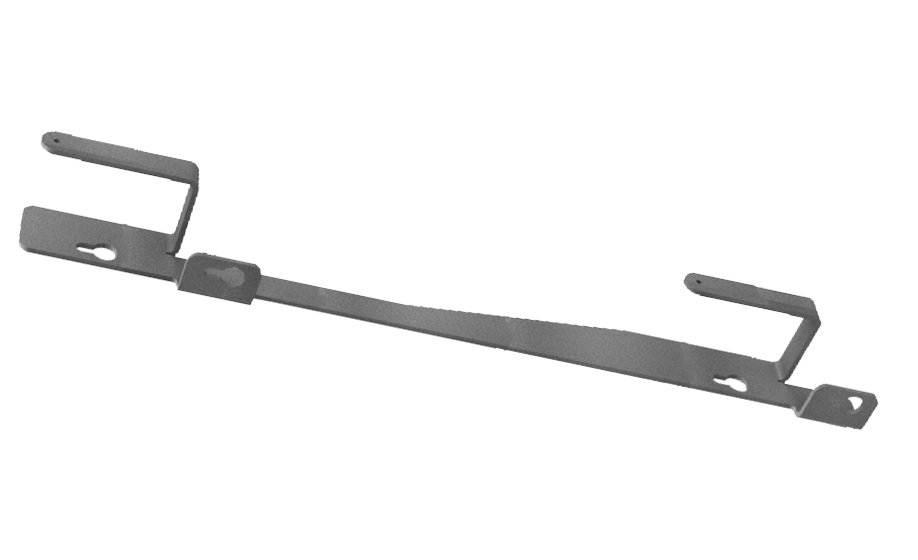

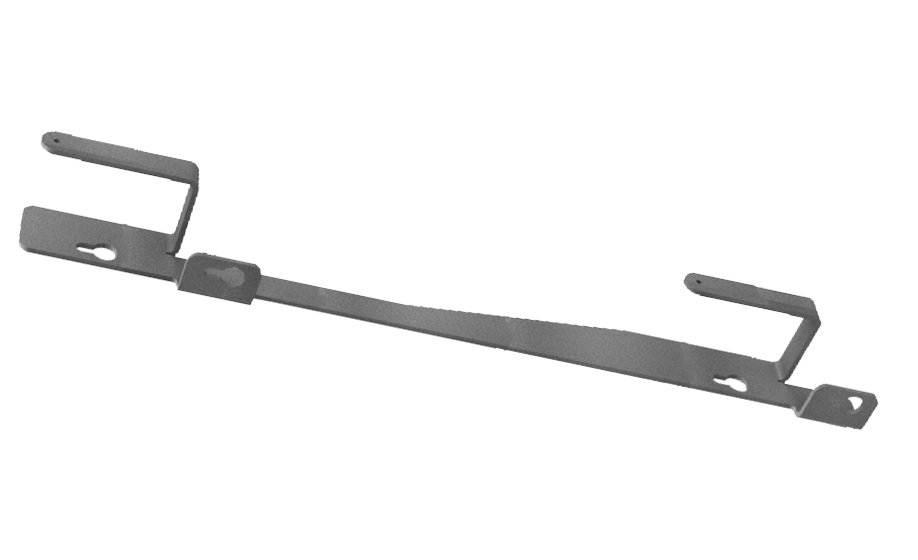

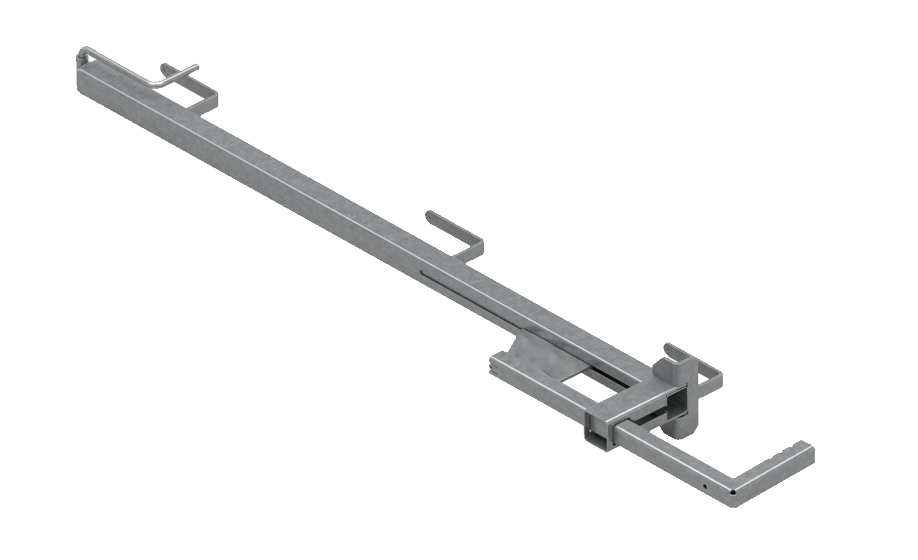

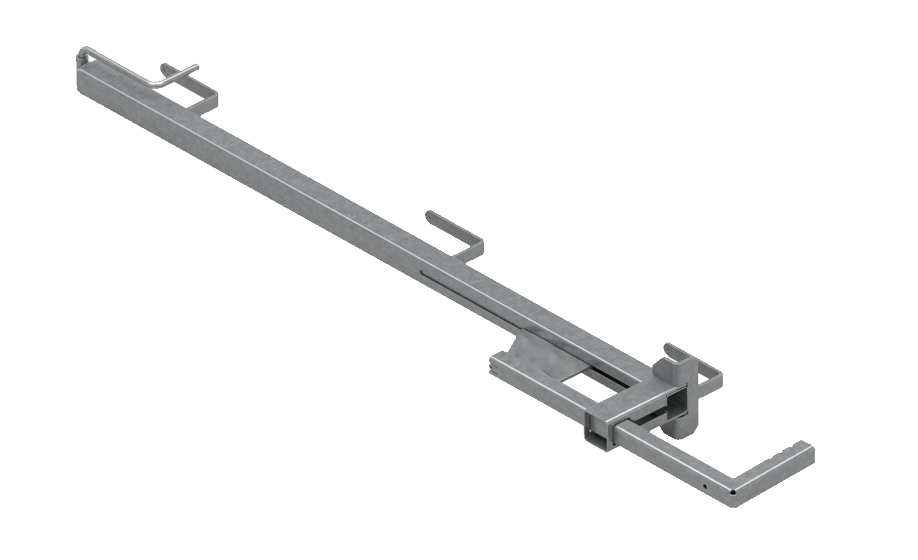

Working platform holder EPS-UPR

| Application: Assembling working platforms in areas determined with two walls. e.g. lift shafts. . |

| Assembly: Use a 16 mm drill bit to make 100 mm deep holes in opposite walls. Insert the holders in the openings, put the beam in holder sockets. The length of the beams must be no shorter than 5 mm of the length between holders. The holder is to be used with walls made of concrete or solid bricks. |

| Weight: 1,8 kg |

| Index: EPS-UPR |

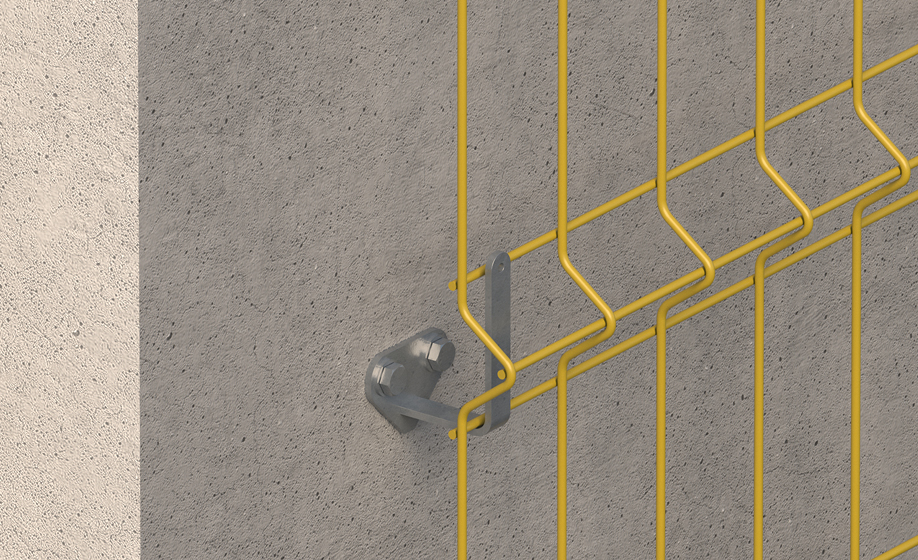

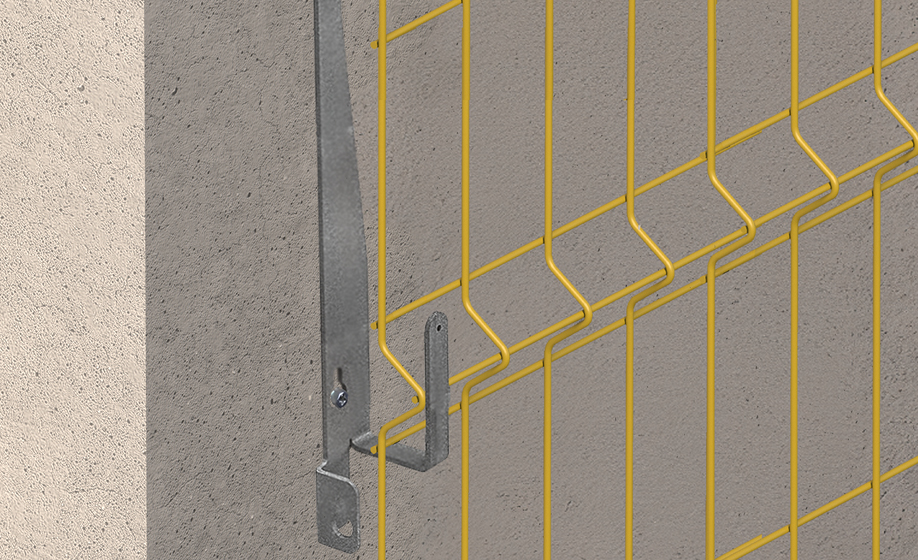

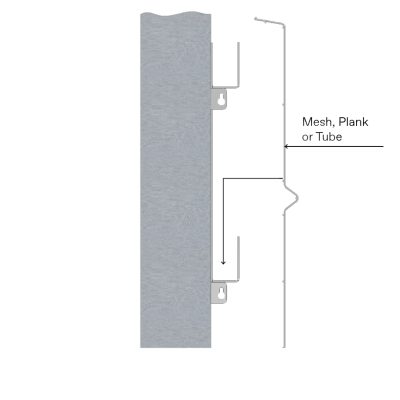

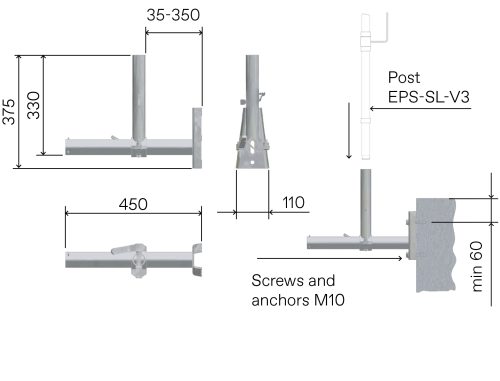

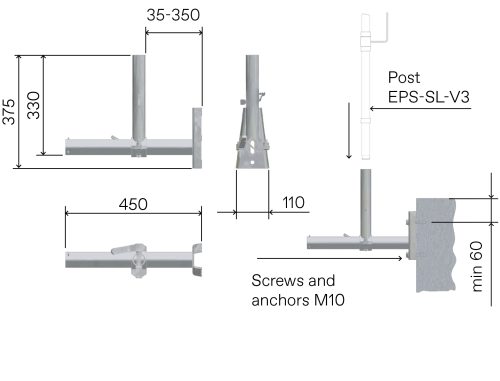

Wall holder EPS-US

| Application: Placing barriers directly on walls In order to protect open spaces such as door and window openings. |

| Assembly: Fix the holder to a vertical surface with two anchors and M10x50 crews. We recommend Fischer EA II M10 anchors which should be fixed according to manufacturer’s Instruction. |

| Weight: 0,3 kg |

| Index: EPS-US |

Wall holder EPS-US2

| Application: Placing barriers directly on walls In order to protect open spaces such as door and window openings. It is possible to mount the support inside the niches. |

| Assembly: The support must be secured with two M10 anchors. The anchors must support a vertical load of 1500N. It is recommended to use the Fischer EA II M10x50 anchor. |

| Weight: 1,7 kg |

| Index: EPS-US2 |

Formwork girder EPS-USZ

| Application: Used to secure edges of the working area. |

| Assembly: The comonenls of the formwork girder should be assembled on buildings supporting structure. If the construction is made of reinforced concrete it is allowed to assemble with chemical ancor or threaded bolt |

| Weight: 14,2 kg |

| Index: EPS-USZ |

Facade holder EPS-USP

| Application: The holder was designed to be assembled on steel and reinforced concrete structures. |

| Assembly: The holder can be assembled on vertical surfaces, under ledges, to such steel beams as I-beams or channels. |

| Weight: 3,9 kg |

| Index: EPS-USP |

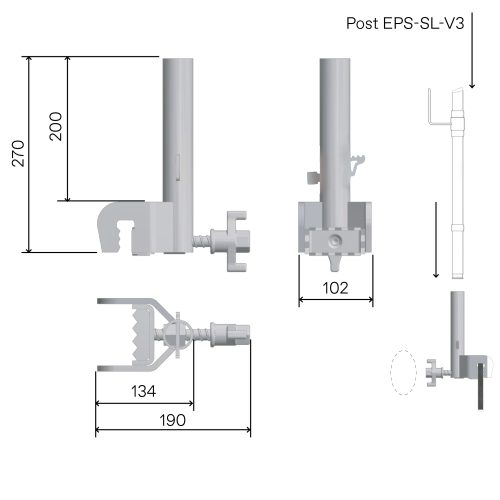

Bracket clamp with post EPS-UUS

| Application: This post can replace two system elements, being a horizontal surface holder and system post in te same time. |

| Assembly: Loose the clamp by twisting the knob until you receive the required holder opening. Put the holder on the surface where it is to be assembled. Clamp the holder using the knob. |

| Weight: 7,2 kg |

| Index: EPS-UUS |

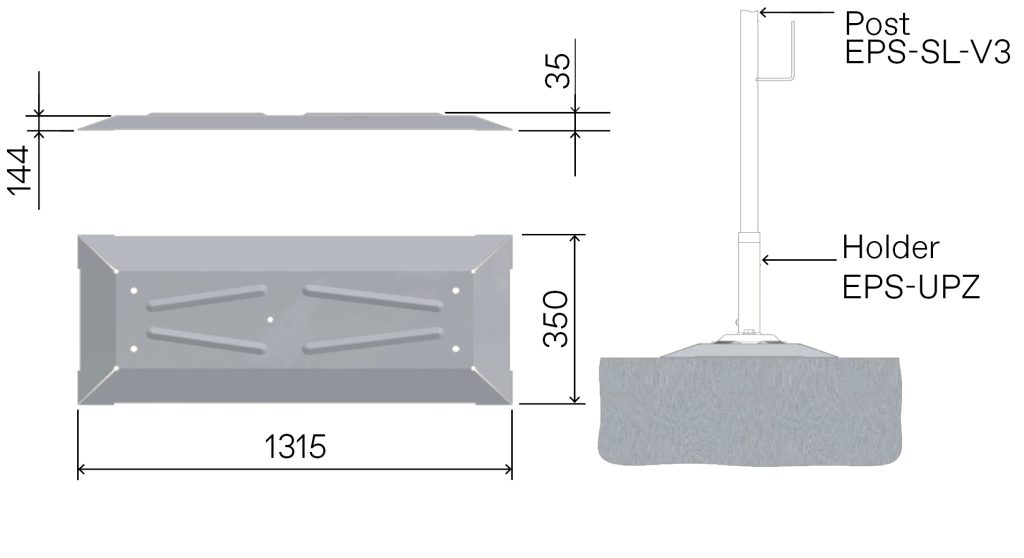

Steel foot EPS-PU

| Application: A foot with standard EPS components, i.e. horizontal holder EPS-UPZ and mesh panels, can be used to fence the construction site. THese feet cannot be used as edge protection. |

| Assembly: Fasten the horizontal holder EPS-UPZ to the foot with M12x40 screws with nuts and pads. The foot with attached holder should be placed in the area that is supposed to be fenced. |

| Weight: 4,8 kg |

| Index: EPS-PU |

Transport

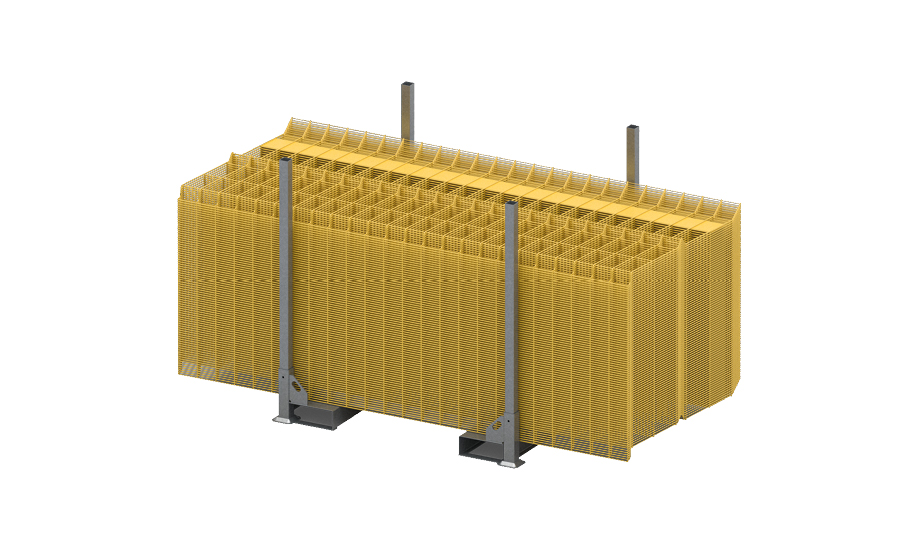

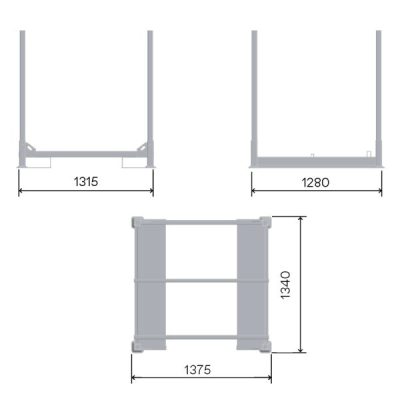

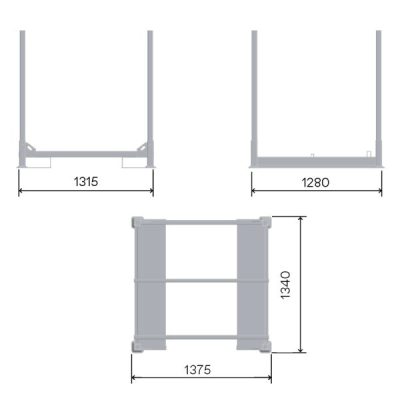

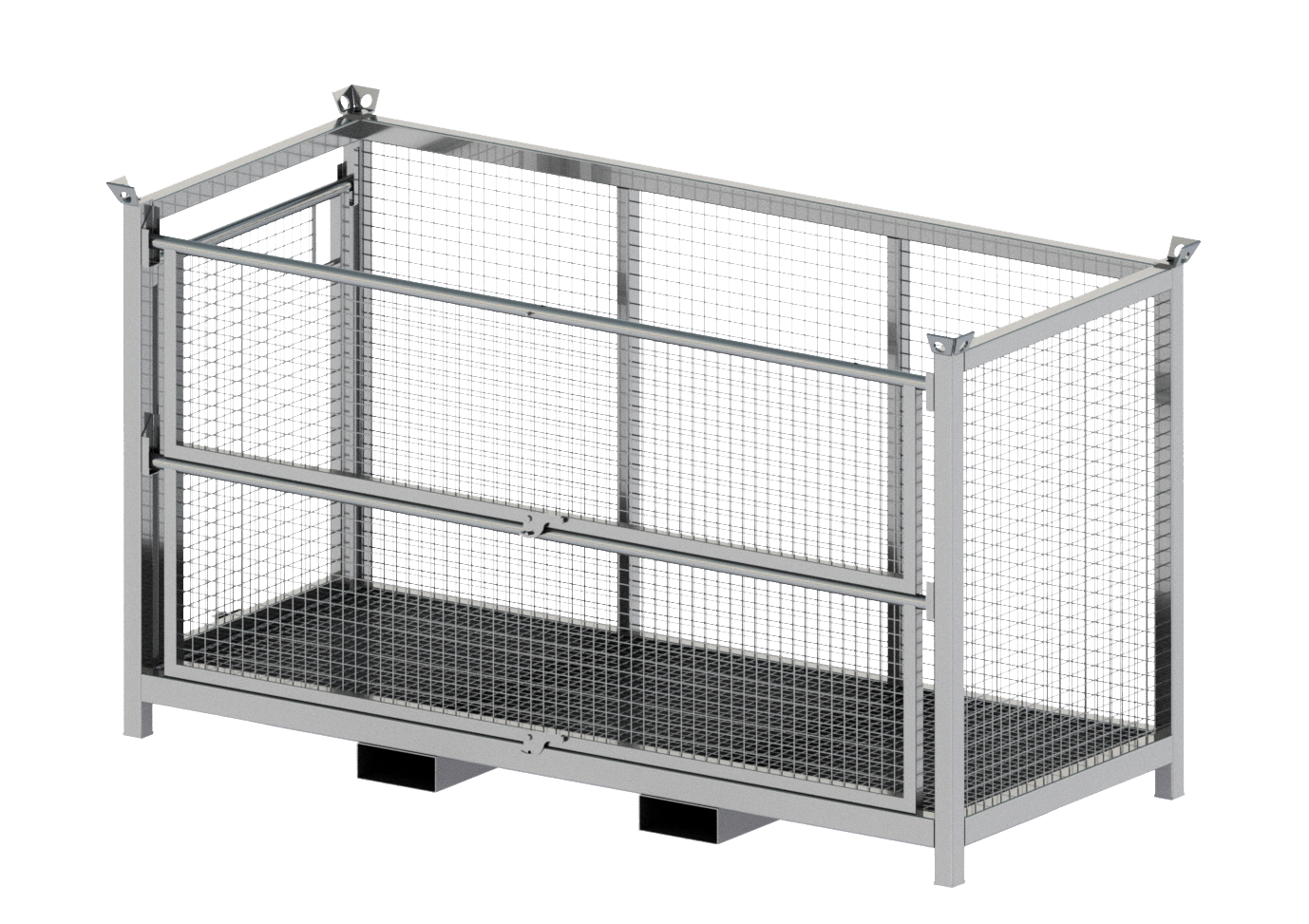

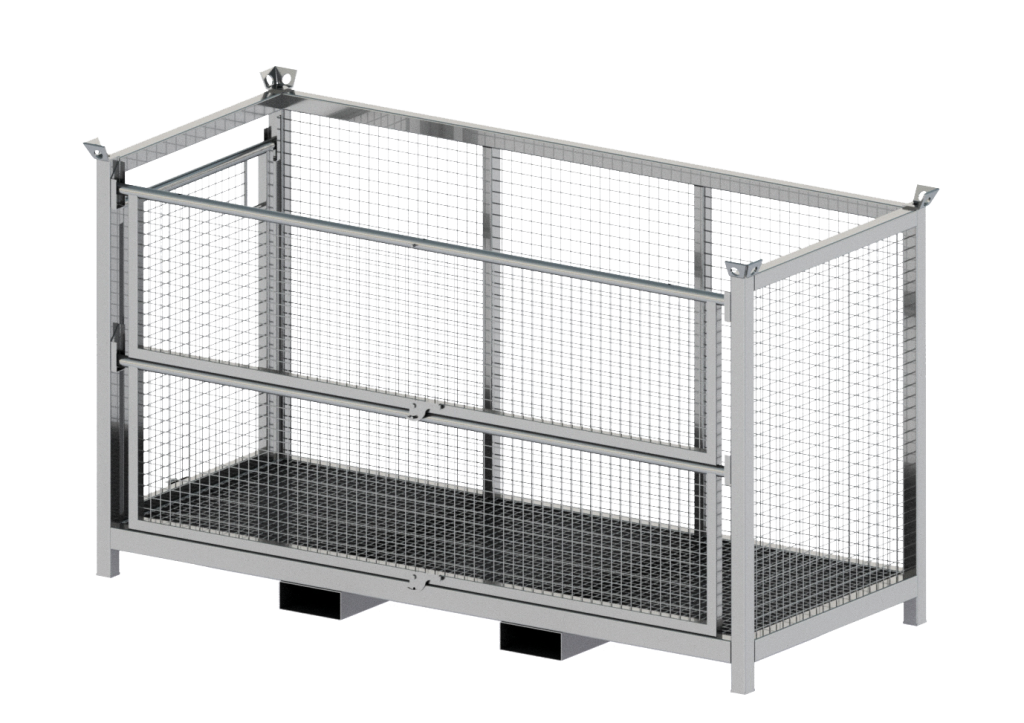

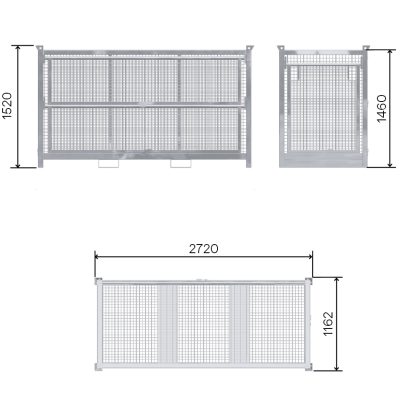

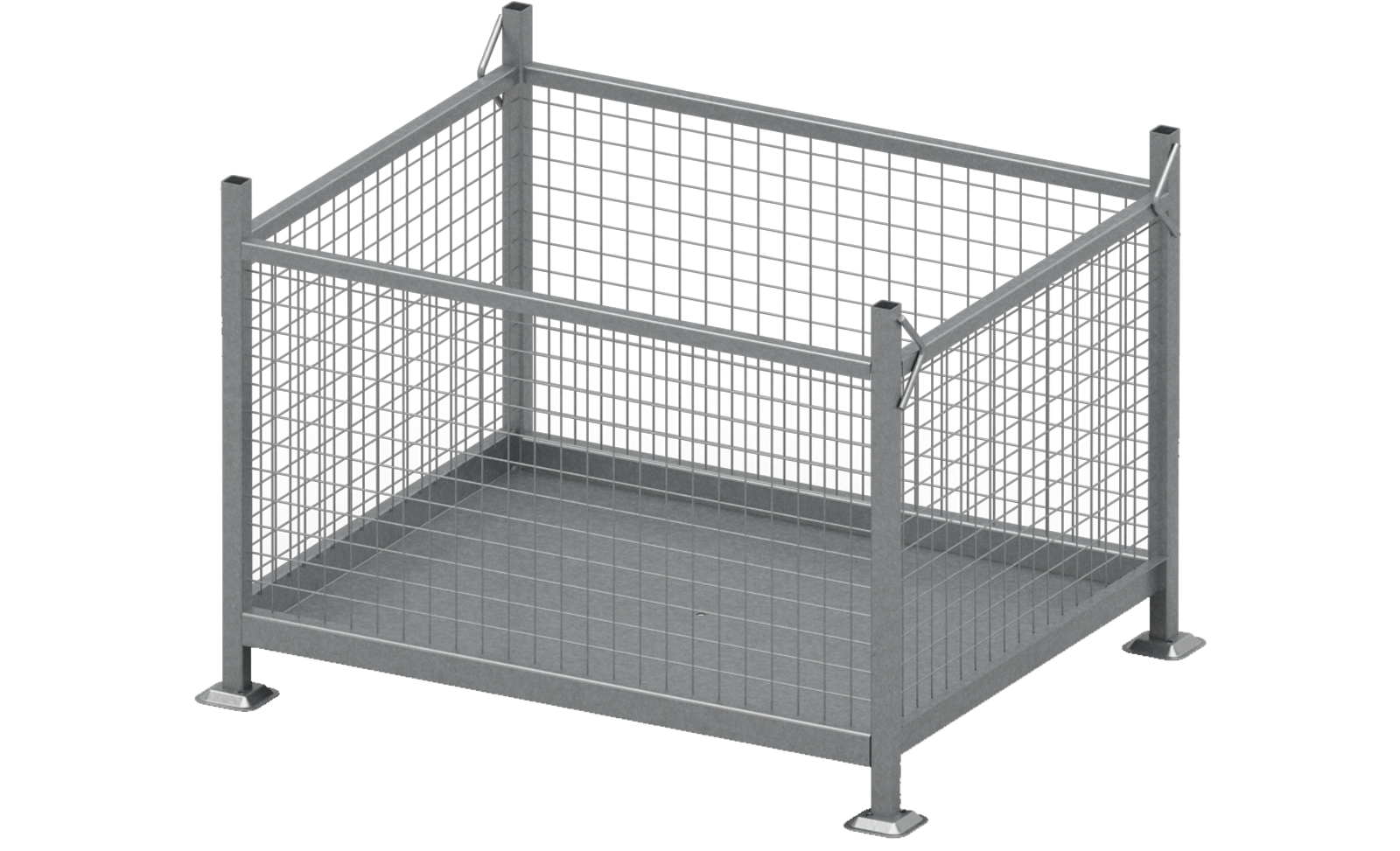

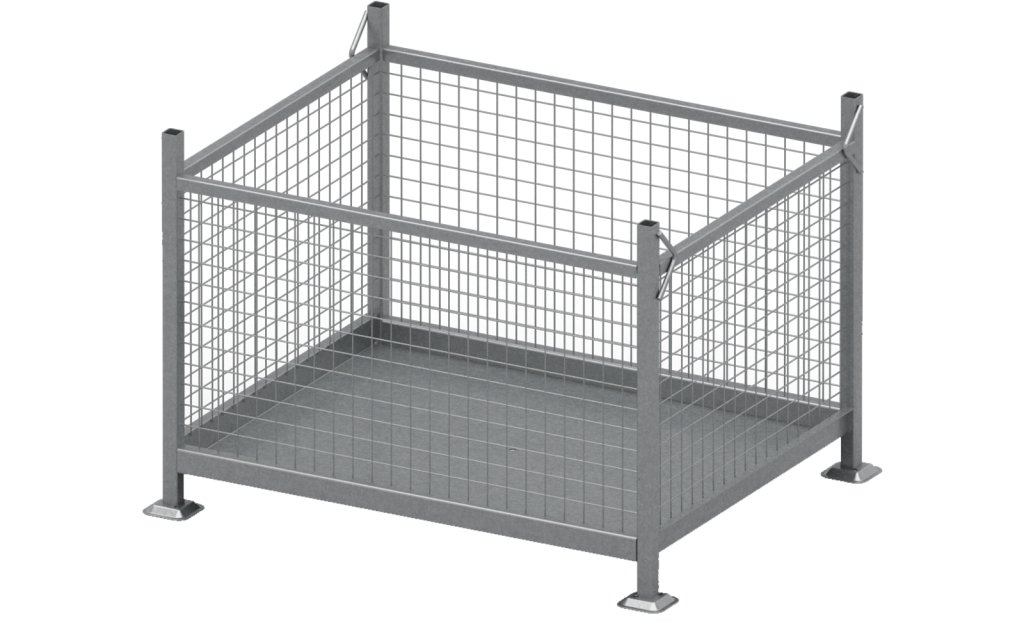

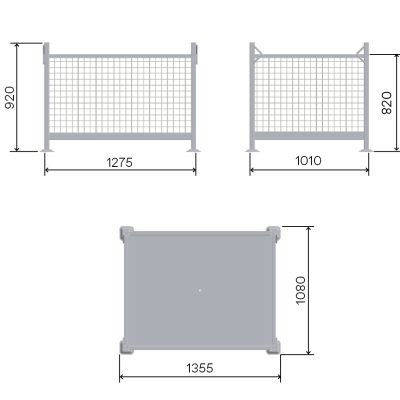

Transport basket W-TM-SD3

| Capacity |

| EPS-PAN-ECO: 100 pcs |

| EPS-D: 230 pcs |

| EPS-R1750: 165 pcs |

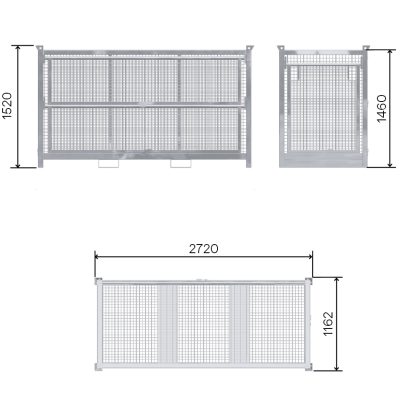

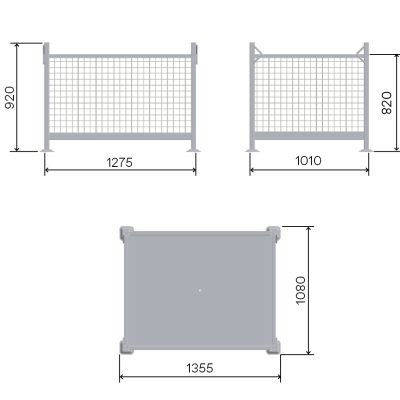

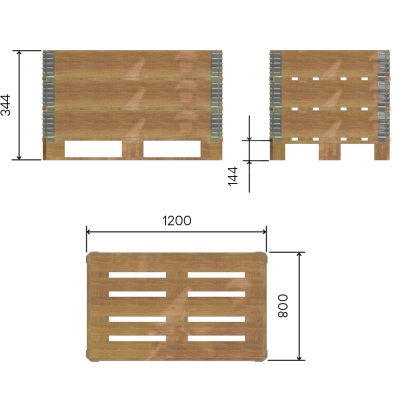

Transport baskets W-TM-SD1

| Capacity |

| EPS-D: 180 pcs |

| EPS-R500: 760 pcs |

| EPS-R700: 480 pcs |

| EPS-R1050: 270 pcs |

| EPS-R1750: 160 pcs |

| EPS-SL-V3: 340 pcs |

| EPS-PRS-V2: 900 pcs |

| EPS-PRS190-V2: 1050 pcs |

| EPS-UPZ-V2: 1000 pcs |

| EPS-UPN-V2: 800 pcs |

| EPS-UDZ-V2: 380 pcs |

| EPS-UG-V2: 450 pcs |

| EPS-UZT-V2: 710 pcs |

| EPS-UUN-L800-V2: 150 pcs |

| EPS-UUN-V4: 180 pcs |

| EPS-UZH-V2: 4500 pcs |

| EPS-UZV-V2: 4500 pcs |

| EPS-UW-V3: 450 pcs |

| EPS-UDS: 5000 pcs |

| EPS-UPR: 670 pcs |

| EPS-US: 5000 pcs |

| EPS-US-2: 1500 pcs |

| EPS-USZ: 90 pcs |

| EPS-USP: 320 pcs |

| EPS-UUS: 180 pcs |

| EPS-PU: 260 pcs |

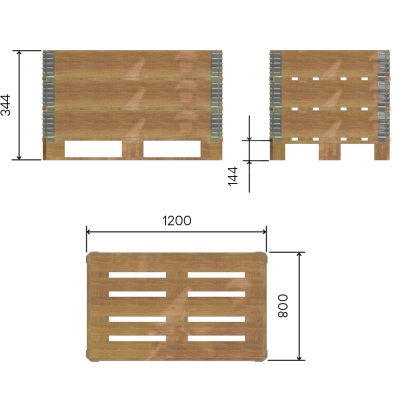

Transport baskets W-TM-SD2

| Capacity |

| EPS-R500: 500 pcs |

| EPS-R700: 350 pcs |

| EPS-R1050: 190 pcs |

| EPS-SL-V3: 270 pcs |

| EPS-PRS-V2: 320 pcs |

| EPS-PRS190-V2: 384 pcs |

| EPS-UPZ-V2: 369 pcs |

| EPS-UPN-V2: 288 pcs |

| EPS-UDZ-V2: 172 pcs |

| EPS-UG-V2: 192 pcs |

| EPS-UZT-V2: 320 pcs |

| EPS-UUN-L800-V2: 52 pcs |

| EPS-UUN-V4: 96 pcs |

| EPS-UZH-V2: 1360 pcs |

| EPS-UZV-V2: 1440 pcs |

| EPS-UW-V3: 153 pcs |

| EPS-UDS: 1600 pcs |

| EPS-UPR: 304 pcs |

| EPS-US: 1600 pcs |

| EPS-US-2: 400 pcs |

| EPS-USZ: 70 pcs |

| EPS-USP: 108 pcs |

| EPS-UUS: 60 pcs |

| EPS-PU: 210 pcs |

Wooden box pallet W-TM-SD4

| Capacity |

| EPS-R500: 500 pcs |

| EPS-R700: 350 pcs |

| EPS-R1050: 190 pcs |

| EPS-SL-V3: 50 pcs |

| EPS-PRS-V2: 220 pcs |

| EPS-PRS190-V2: 220 pcs |

| EPS-UPZ-V2: 250 pcs |

| EPS-UPN-V2: 190 pcs |

| EPS-UDZ-V2: 110 pcs |

| EPS-UG-V2: 130 pcs |

| EPS-UZT-V2: 220 pcs |

| EPS-UUN-L800-V2: 30 pcs |

| EPS-UUN-V4: 60 pcs |

| EPS-UZH-V2: 930 pcs |

| EPS-UZV-V2: 980 pcs |

| EPS-UW-V3: 100 pcs |

| EPS-UDS: 1050 pcs |

| EPS-UPR: 200 pcs |

| EPS-US: 1050 pcs |

| EPS-US-2: 280 pcs |

| EPS-USZ: 50 pcs |

| EPS-USP: 60 pcs |

| EPS-PU: 200 pcs |

FAQ

The basis of the system consist in mounting brackets and posts. The max distance between the brackets is 2450 mm for guard railing with grating and 2000 mm for plank railing.

The EPS Edge Protection System has been tested by the Institute of Mechanised Construction and Rock Mining for compliance with the PN-EN 13374:2013 standard and has received a Certificate of Conformity. Additionally, the system meets the requirements of the Ordinance of the Minster of Infrastructure on occupational health and safety in building works of 6th February 2003.

The fall protection railing must be at least 110-cm high.

The EPS Edge Protection System consist of the following components: - mounting brackets installed on the structural, load-bearing part of the building - a post equipped with hooks for mounting of the security grating, system planks or system pipes - security grating, system planks or system pipes

Installation of the system does not require highly qualified personnel. However, it is necessary to read the operation and maintenance documentation and installation manual before installing and using the system.

See our lates projects

EPS Edge Protection Systems for the Vibe office building