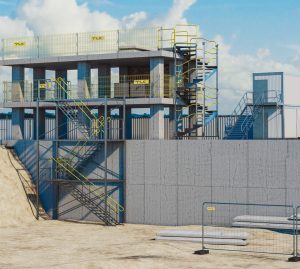

EPS edge protection system

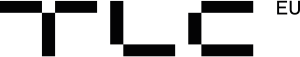

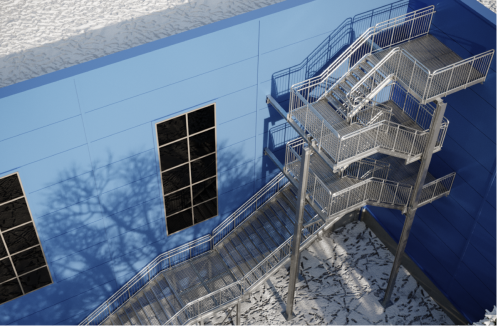

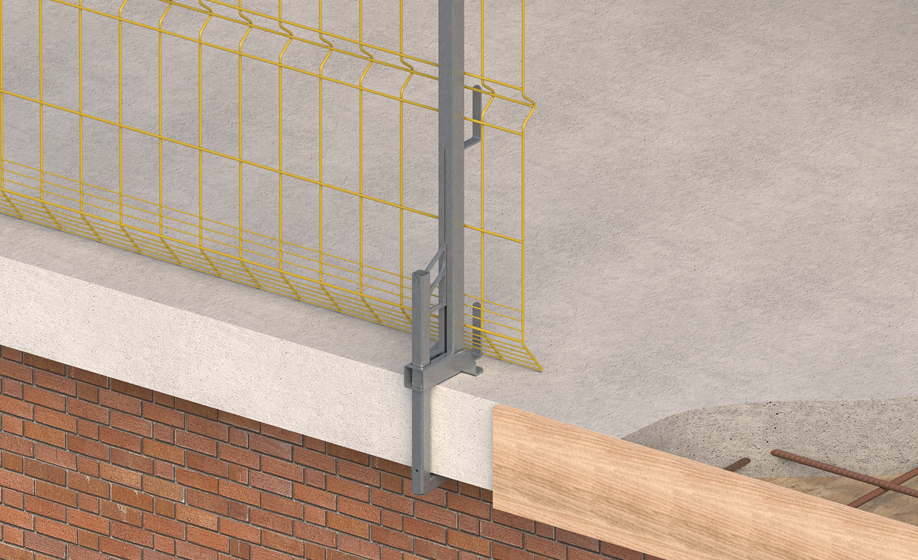

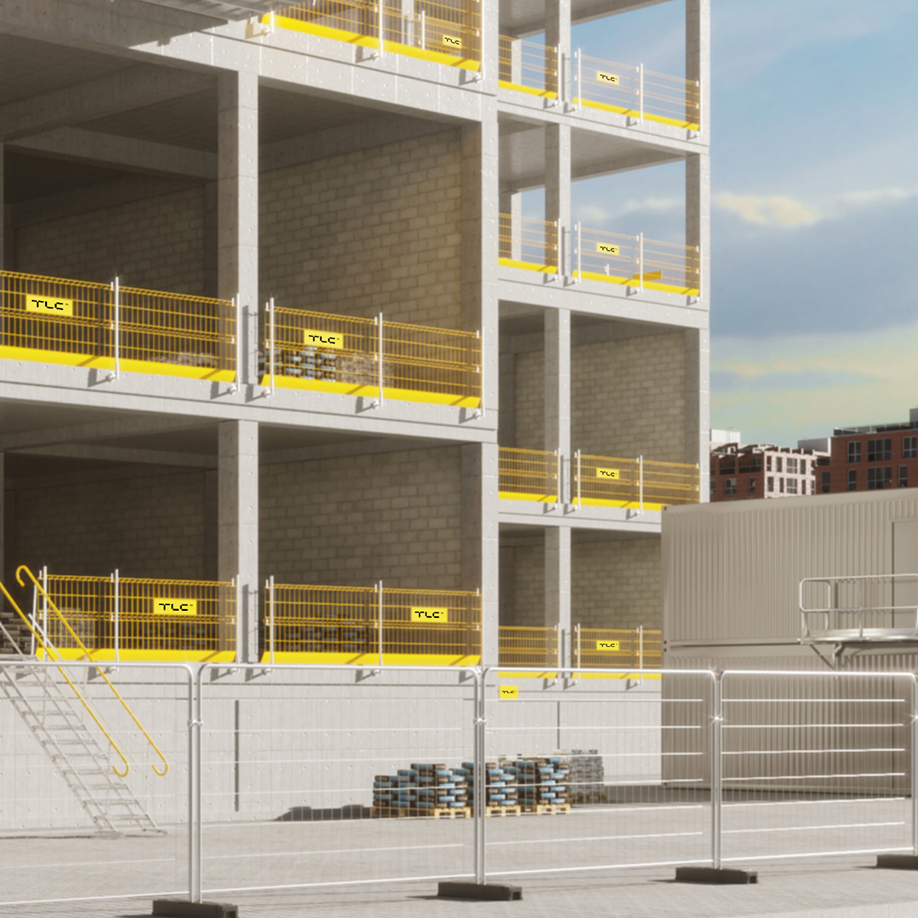

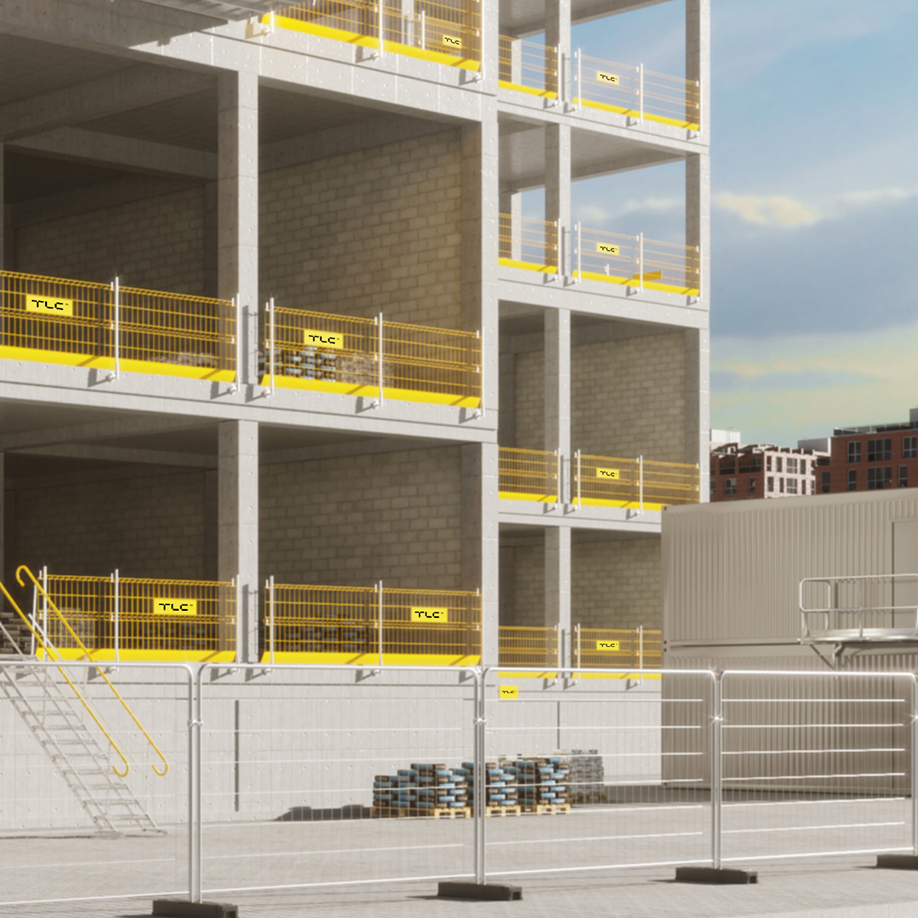

Our Edge Protection System is a modern fall protection system designed to secure building and construction edges, technological openings (elevators, etc.), roof edges, passageways and other areas where there is risk of falling from height.

Meeting all European safety standards, EPS ensures that any construction site meets all EU regulations, which can be rigorous in the industry. It does this by offering protection from falls, through its engineered edge fall prevention system.

Edge Protection System is a modern security system made in compliance with the class A EN 13374:2013-08 standard, dedicated to secure building and construction site edges, technological openings, passaweways and other places where there is risk of falling from height.

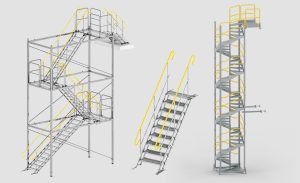

Standard features of available solutions

- Easy, well-thought out and tested solutions that quarantee reliability and the highest possible safety level

- Robust anti-corrosive protection to provide long-term durability of all elements even if exploited

- Assebbly of the system elements does not require highly-qualified personnel

- Wide offer of holders and fixings

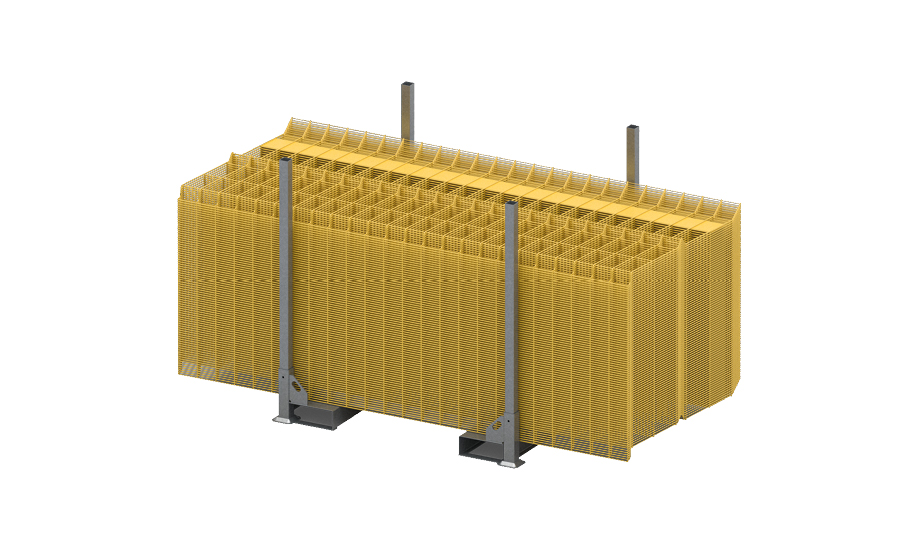

- Special transport baskets facilites loading , unloading, transport and storage of all elements

- The product received a positive opinion of Mechanised Construction and Rock Mining Institute for compliance with EN 13374:3013-08 standard

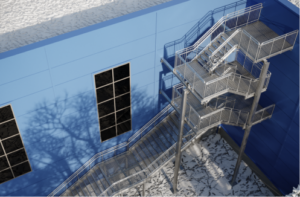

How to install an edge protection system?

Selection and choice of an edge protection system should be adopted to the needs and conditions of the site. The basic factors to be taken into account while installing such a system are frequency of works at a given site and material/ground on which the system will be installed.

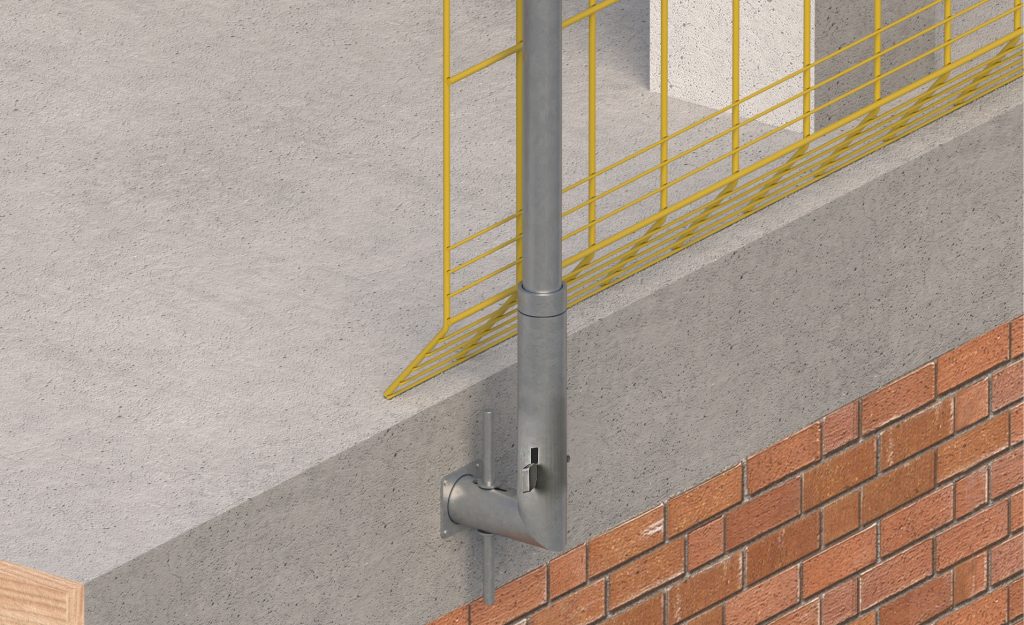

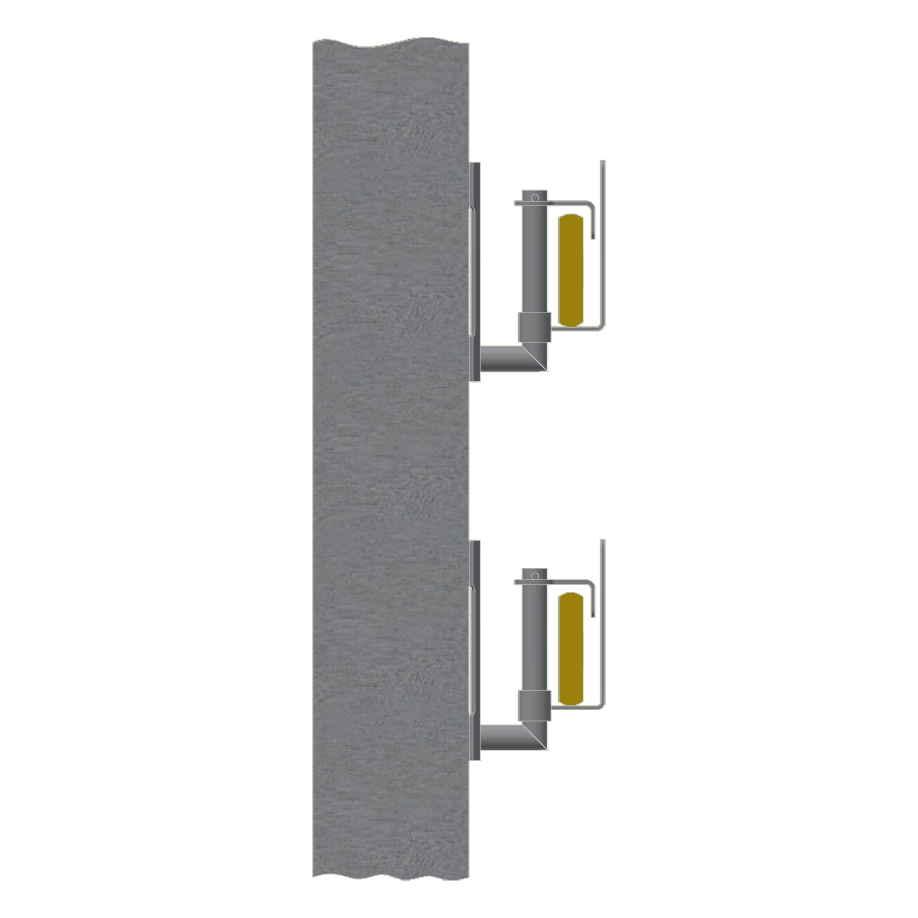

The basic components of the system are the universal posts and mounting brackets. The posts are compatible with all mounting brackets, while the wide variety of those brackets allows for using the system on every stage of construction works. Detailed information on how to install the brackets correctly can be found in the catalogue available in the EPS system tab. Moreover, our experienced employees will gladly provide additional information and configure the system to fit your individual needs.

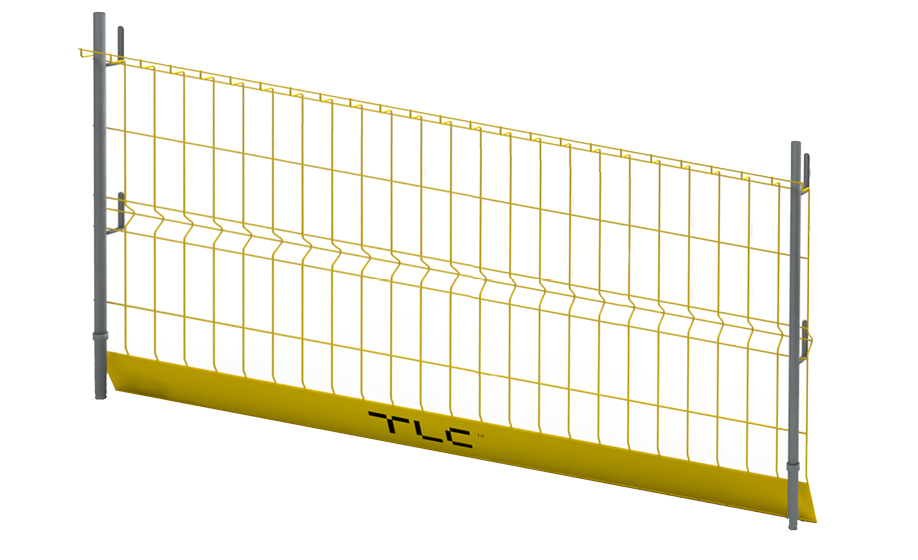

The EPS Edge Protection System is an advanced safety solution designed to prevent falls and enhance security on construction sites. Engineered for versatility and durability, the system consists of universal posts, strong mounting brackets, and high-quality mesh barriers, ensuring reliable protection in various working environments.

Thanks to its modular design, the EPS system can be easily adapted to different construction phases, providing maximum stability and compliance with international safety standards. The hot-dip galvanized steel components guarantee long-lasting resistance to harsh weather conditions, making it an essential safety feature for both temporary and permanent applications.

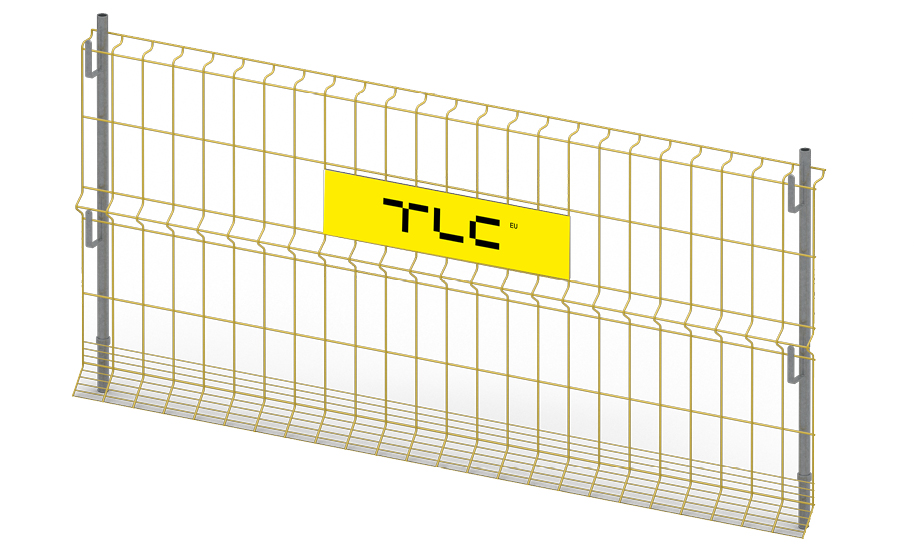

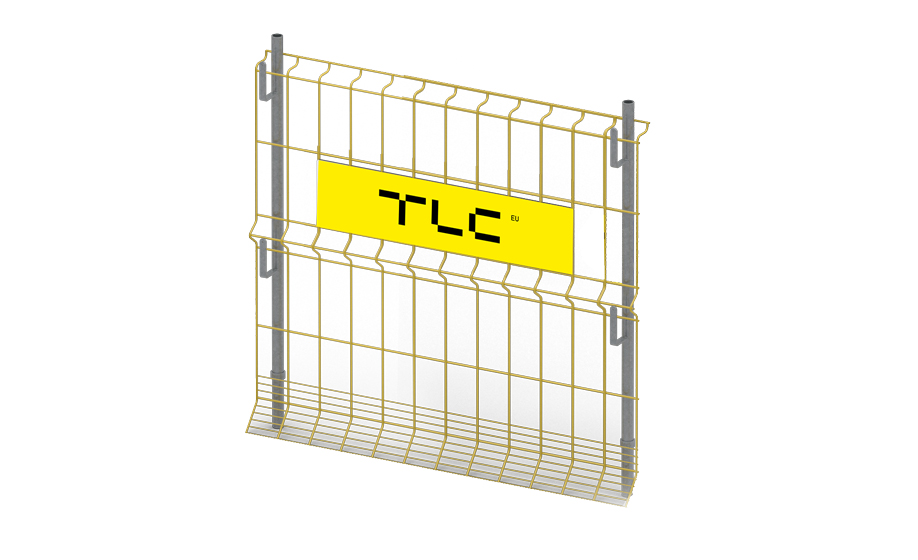

Panels

EPS ECO Panel 1100x2500mm – consists of galvanized steel rods which are resistant. The maximum...

Eco Panel 1100x1250mm – consists of galvanized steel rods which are resistant. The maximum distance...

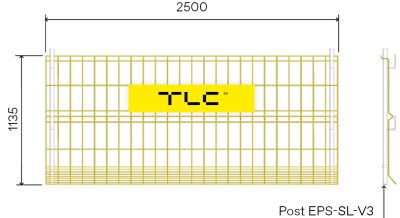

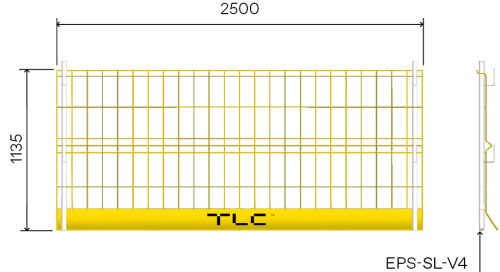

Panel 1100x2500mm – consists of galvanized steel rods which are resistant. The maximum distance...

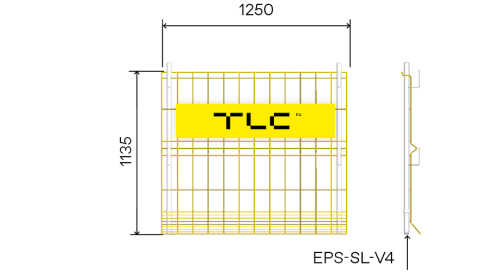

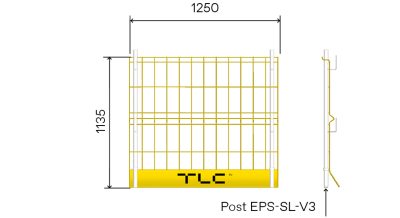

Panel 1100x1250mm - consists of galvanized steel rods which are resistant. The maximum distance...

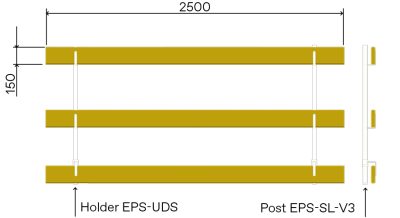

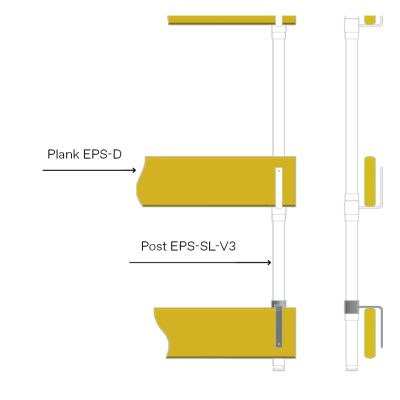

Timber planks in 2500 x 150 mm dimension. The maximum span between the posts is 2000 mm. Available...

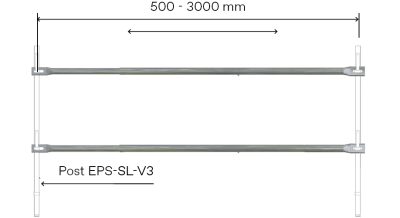

Scaffolding tube is made of steel and assembled on system post hooks.Application:...

Holders and post

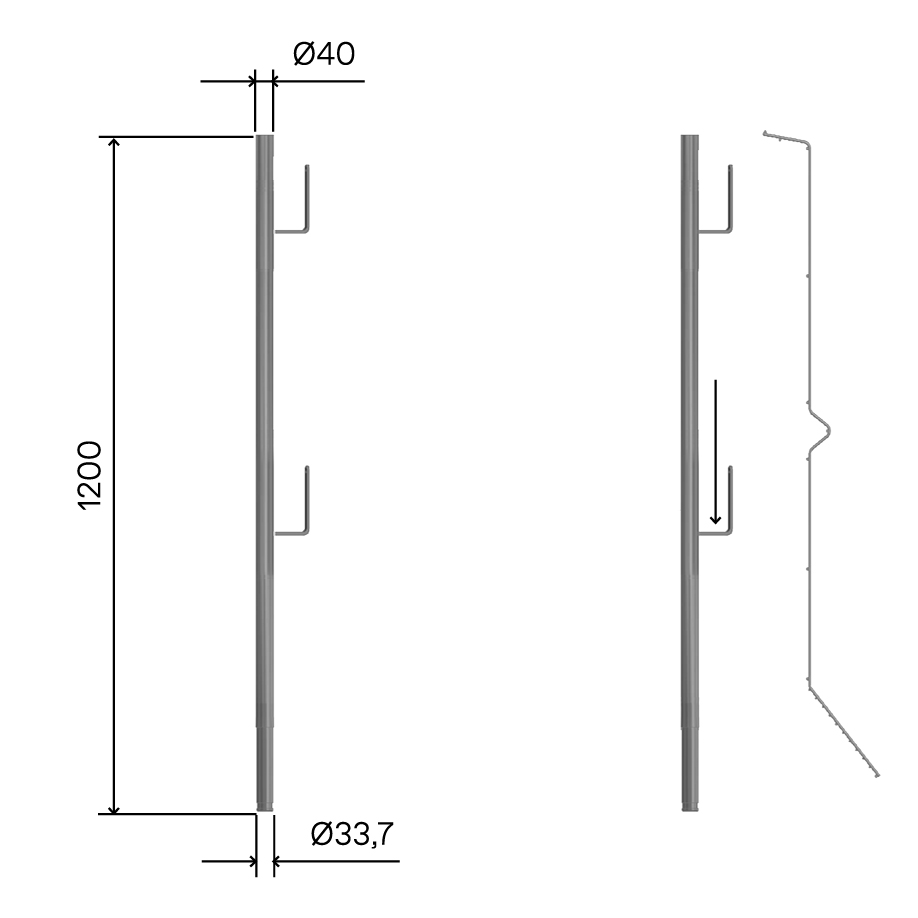

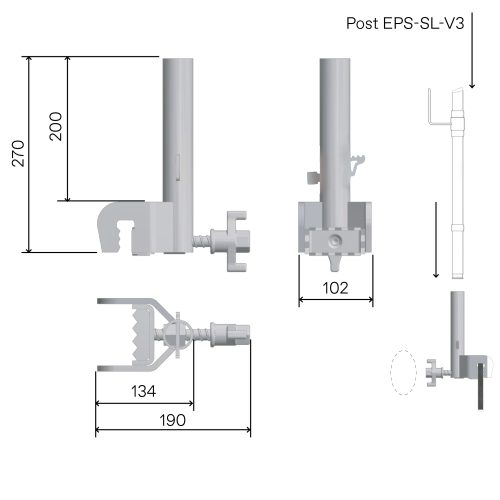

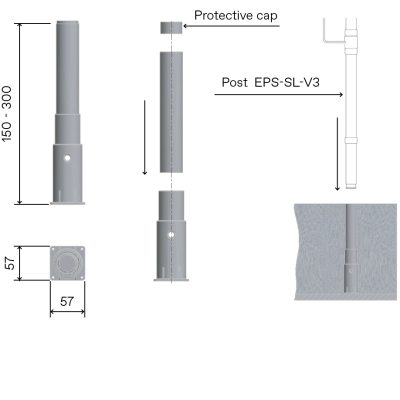

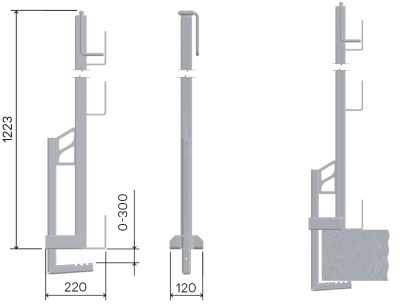

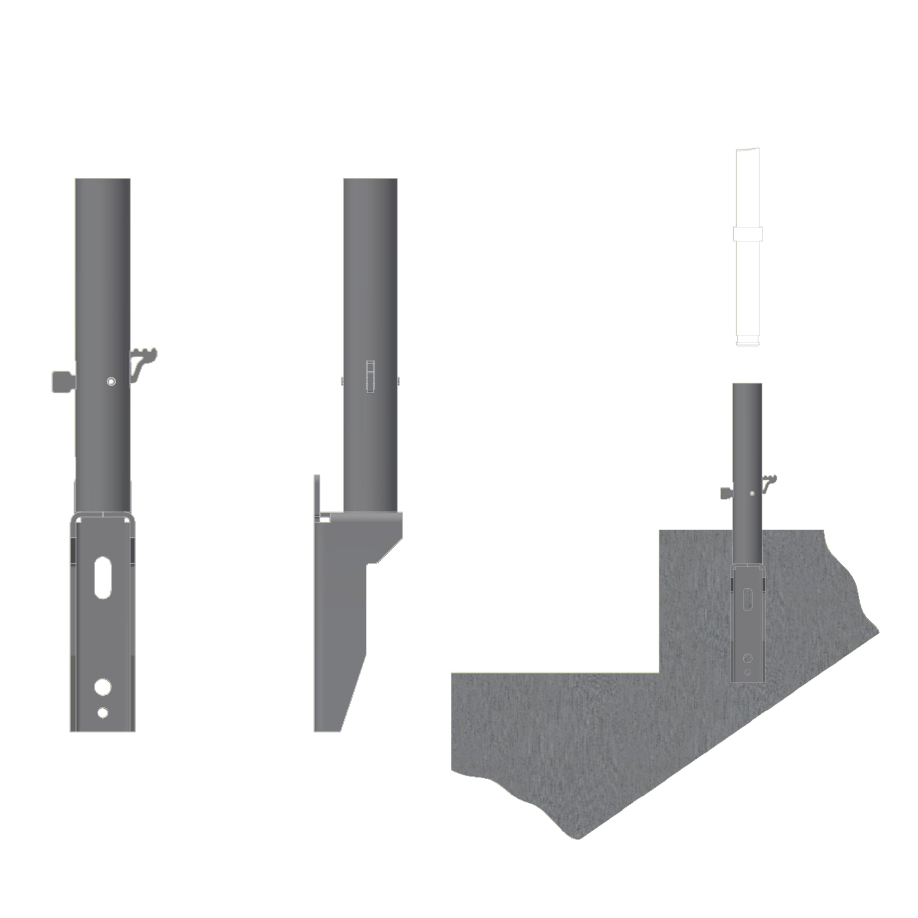

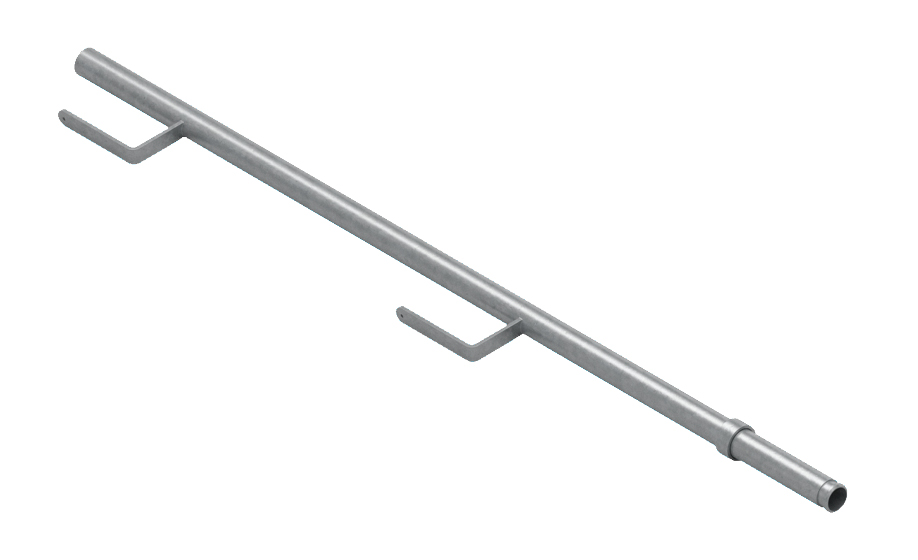

System post with two universal hooks that allow for assembly of any railing...

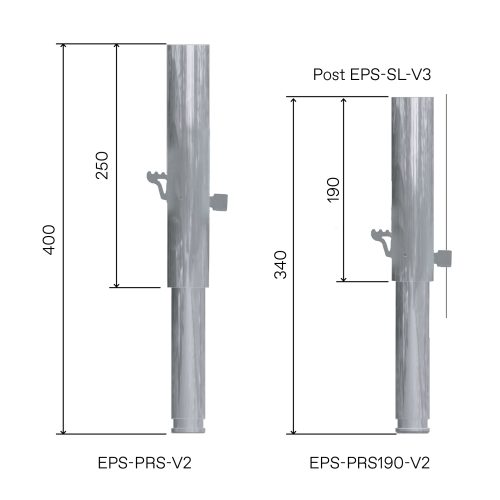

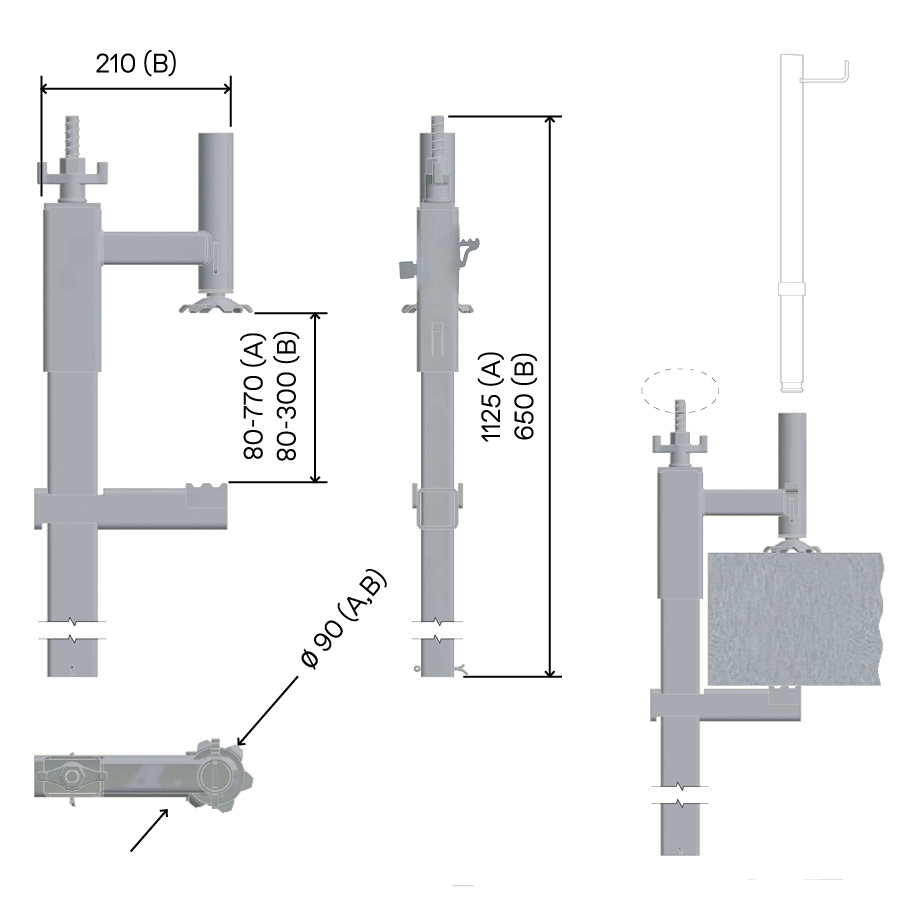

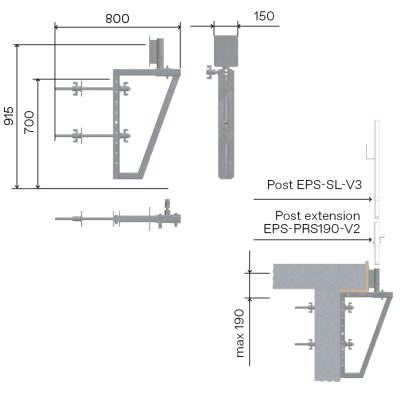

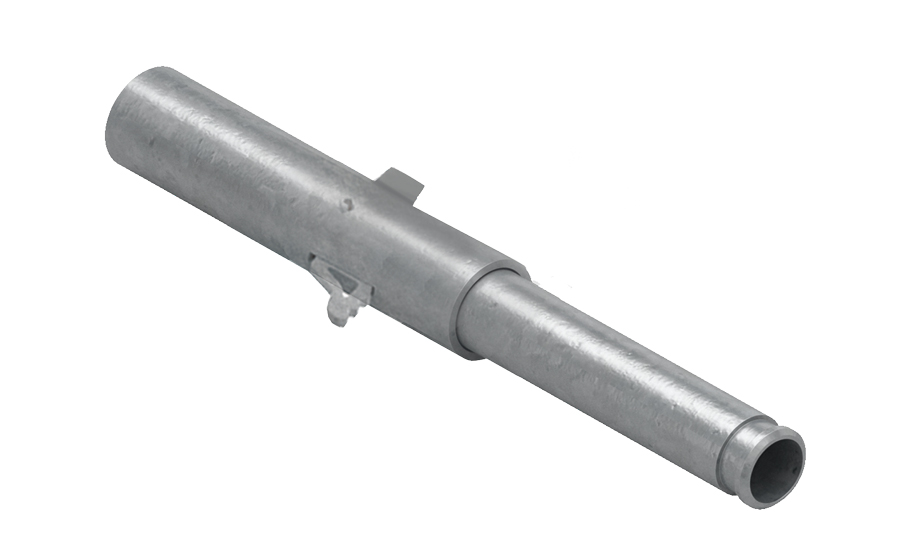

Available in two sizes: 190 and 250 mm.Application: Extending the universal pole to obtain...

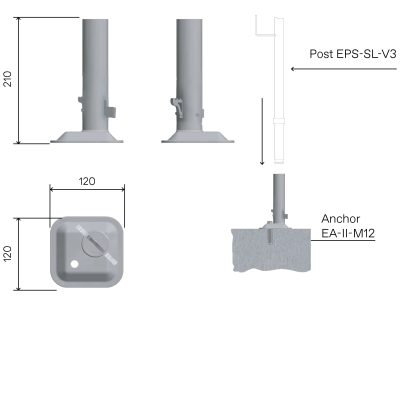

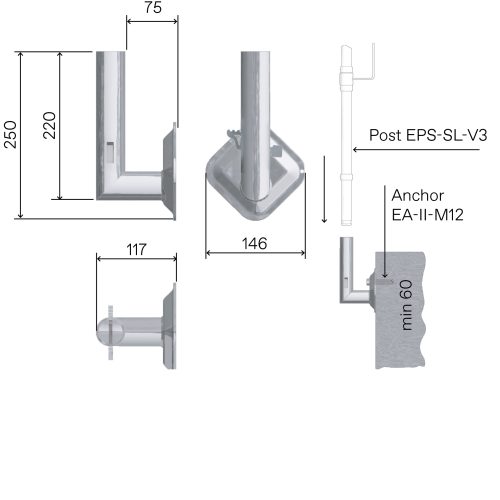

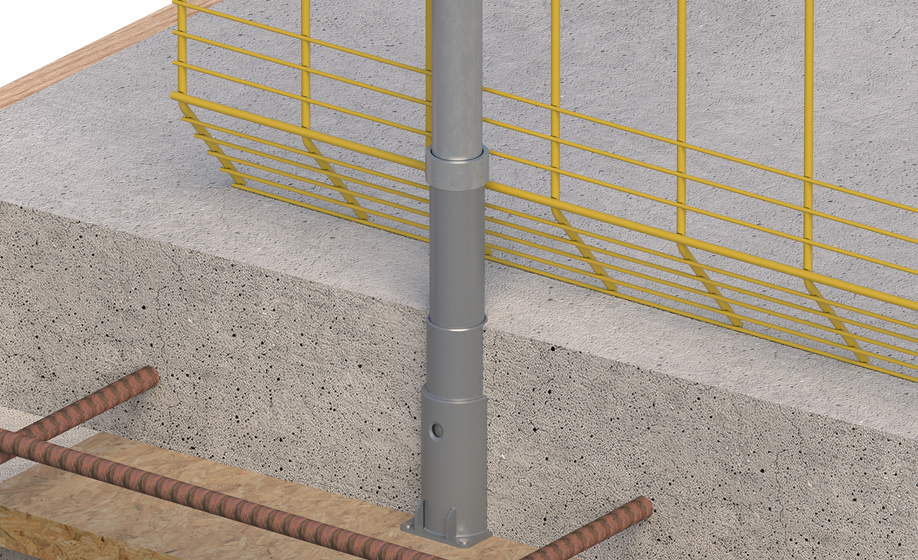

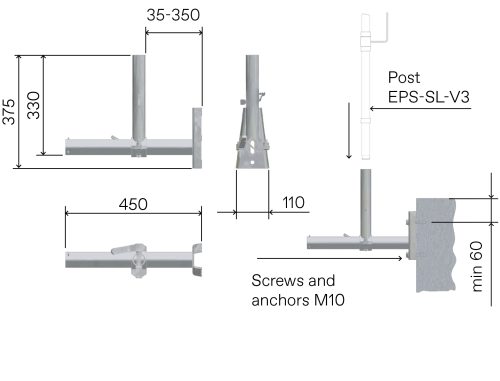

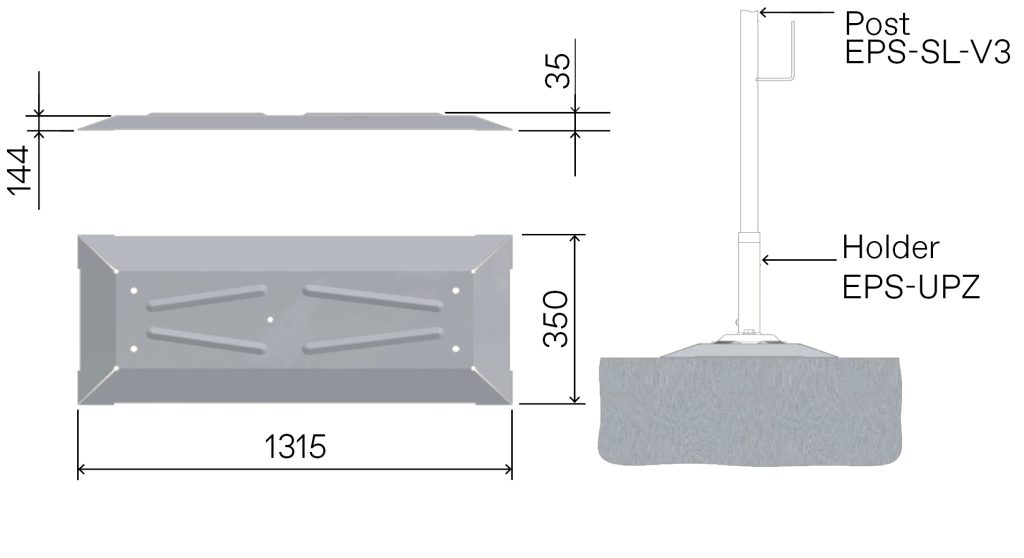

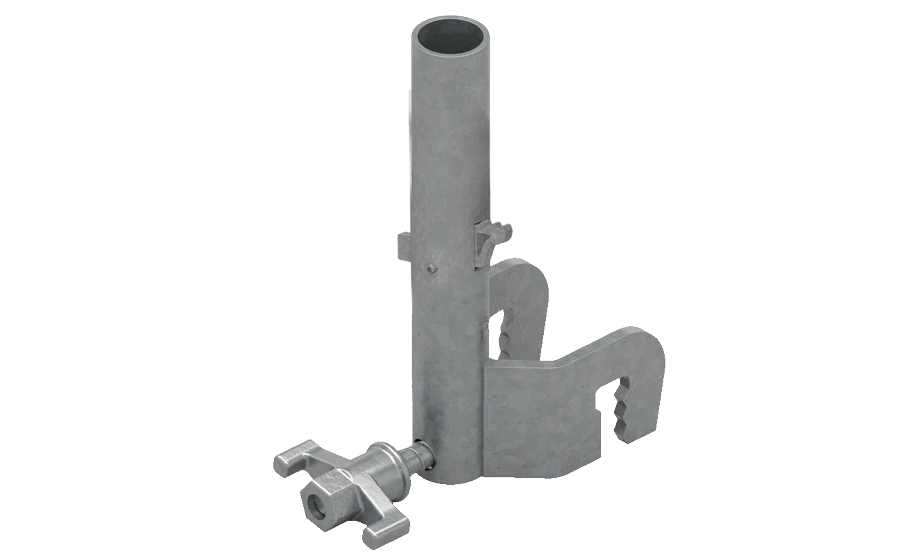

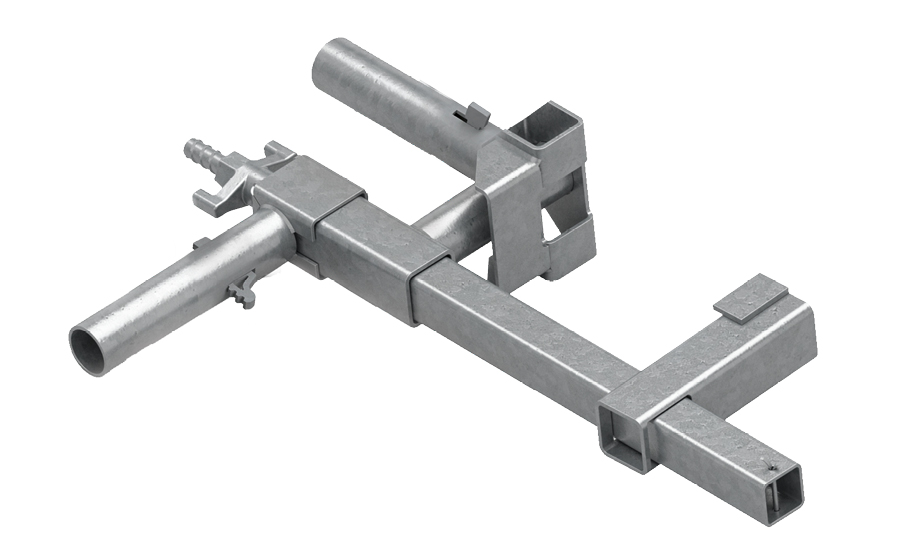

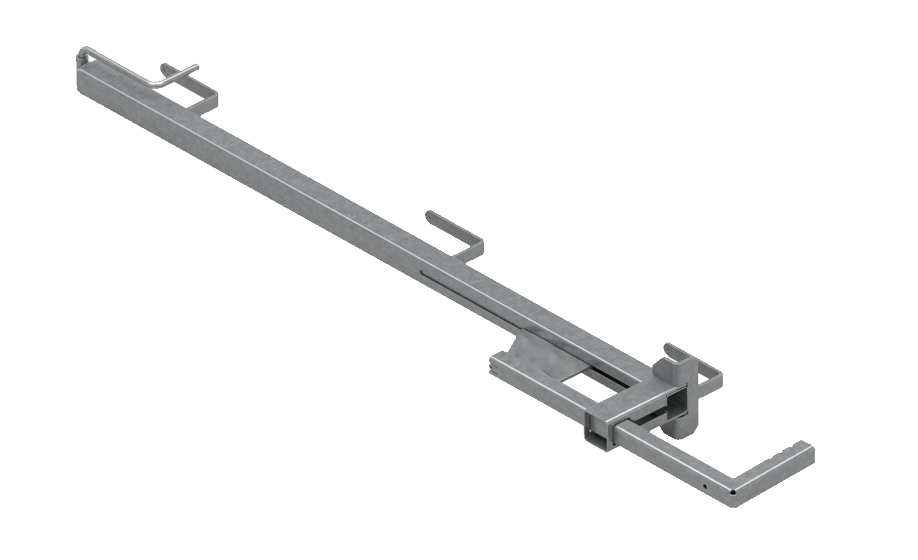

Application: Assembling the guardrail post on horizontal working surfaces, e.g. building...

Designed to avoid interference with most of the construction works.Application: Assembling...

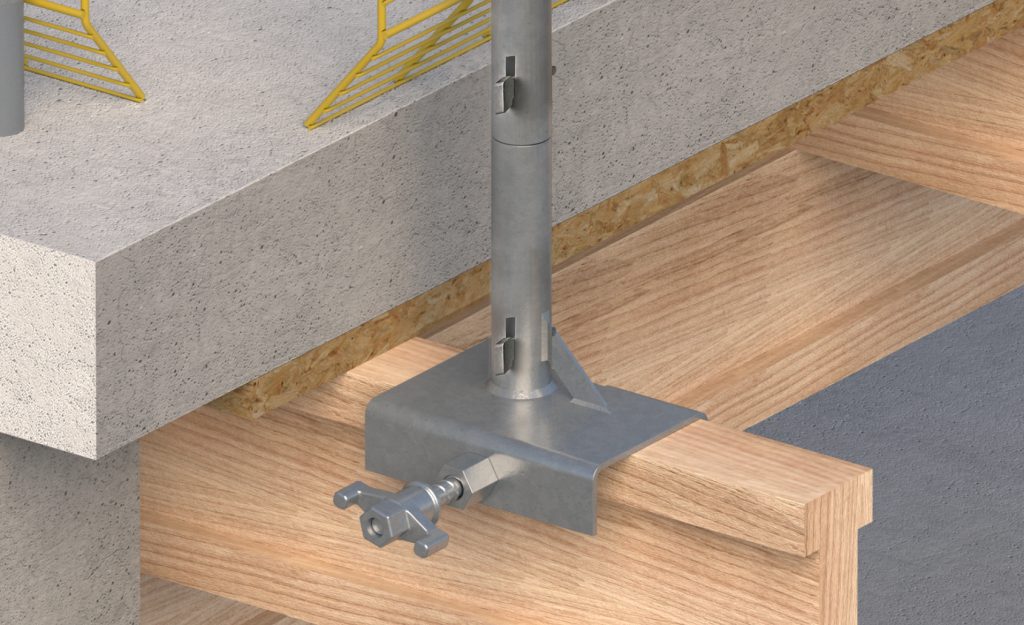

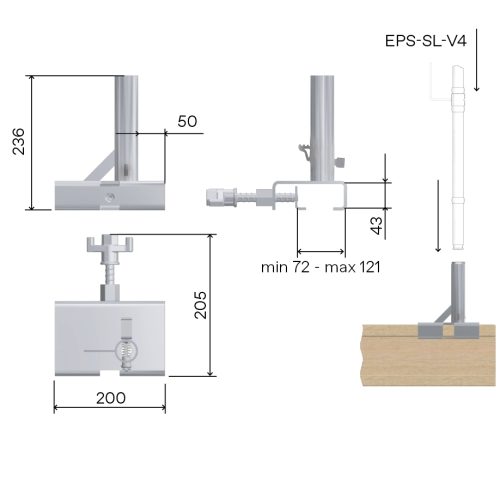

Suitable for every girder height with maximum width of the upper T being 95 mm.Application:...

Holder for steel structure to improve clamping of the holder equipped in teeth fostening...

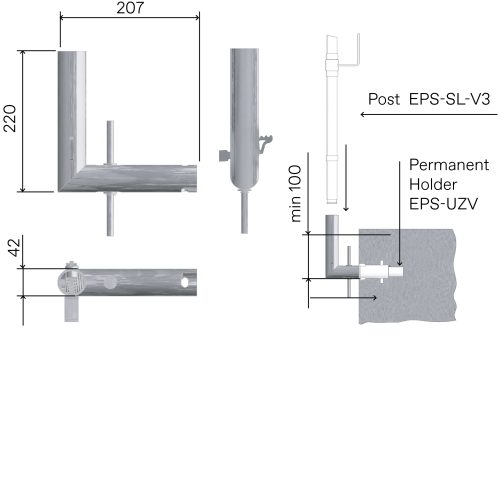

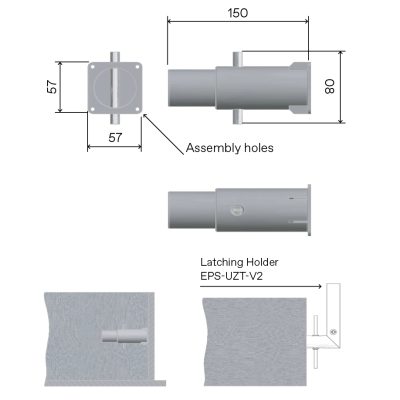

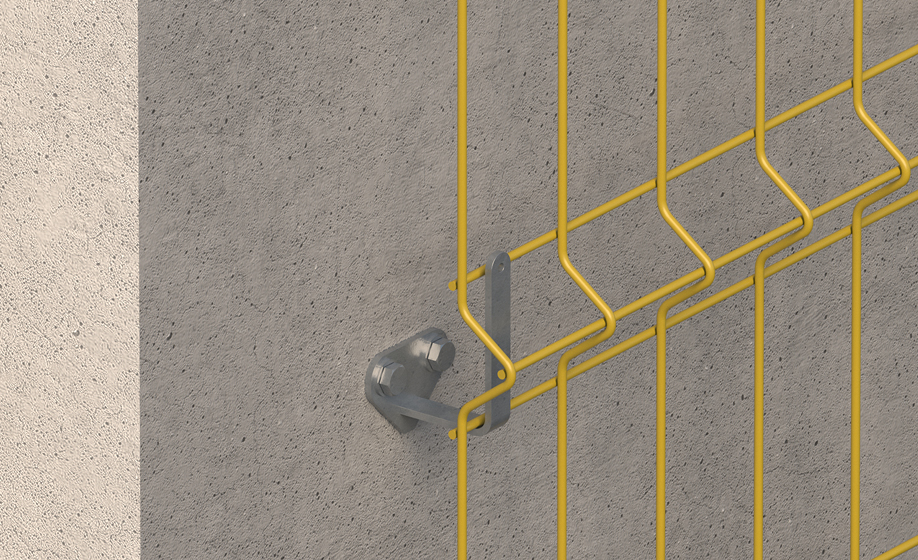

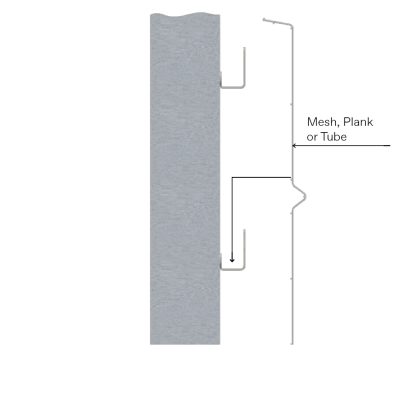

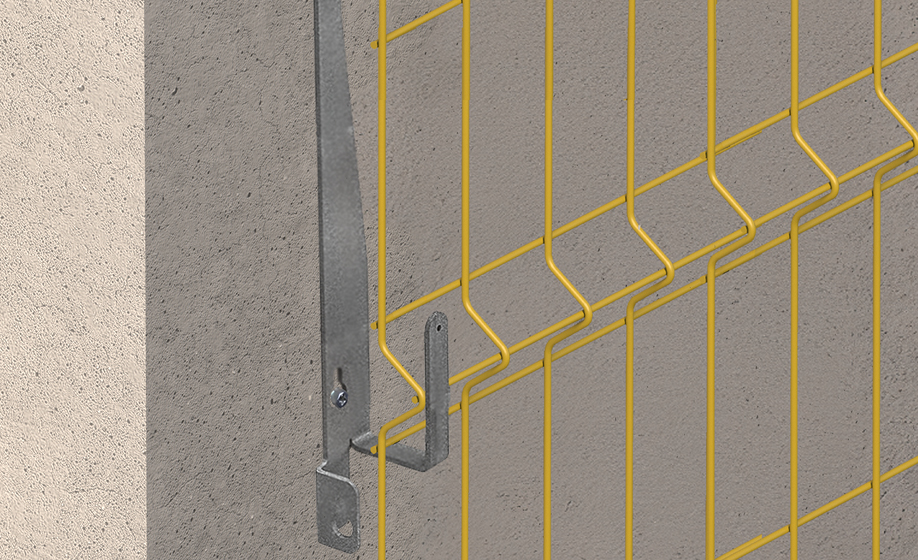

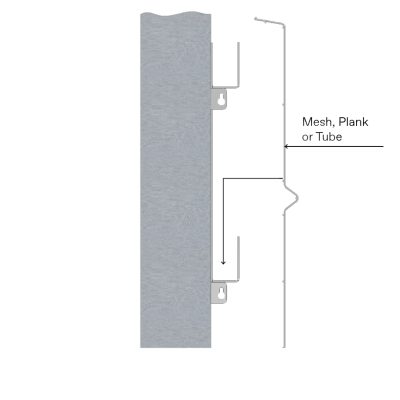

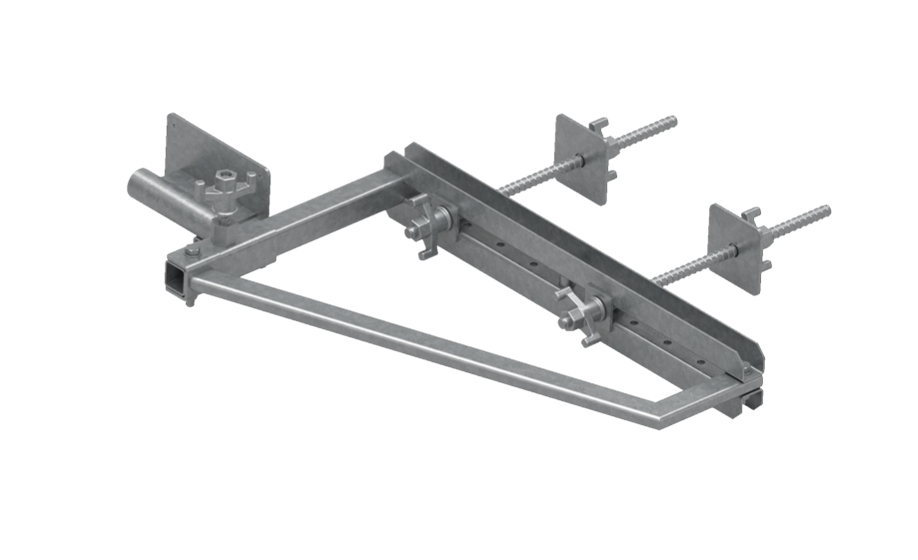

Application: Assembling the guardrail post on vertical surfaces to previously prepared...

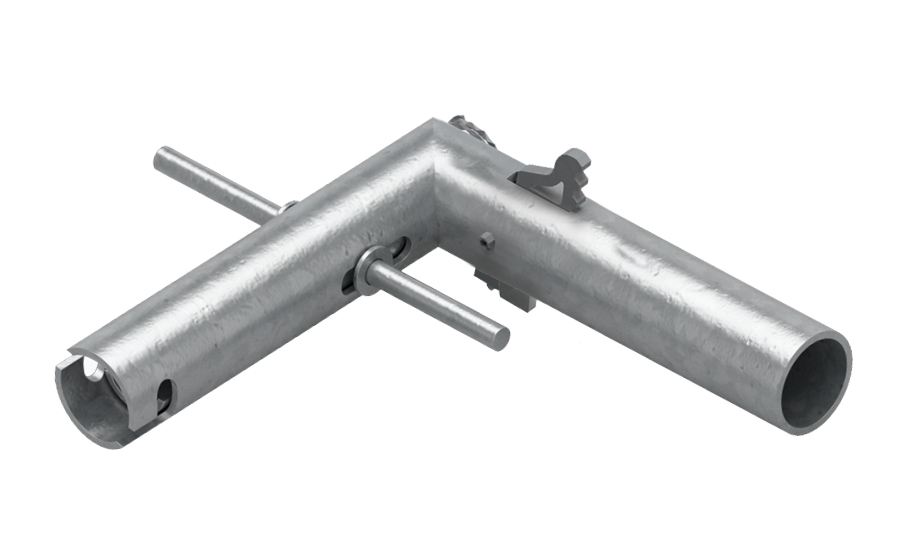

Universal solution used in numerous configurations. It allows assembly without compromising the...

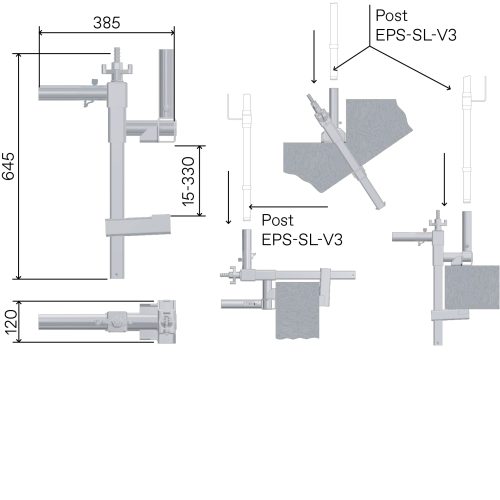

The holder construction allows to clamp items from 15 to 330 mm thick..Application:...

Resistant to most of the materials used at the construction site, e.g. concrete mixture, cream of...

Resistant to most of the materials used in construction sector, e.g. concrete mixture, cream of...

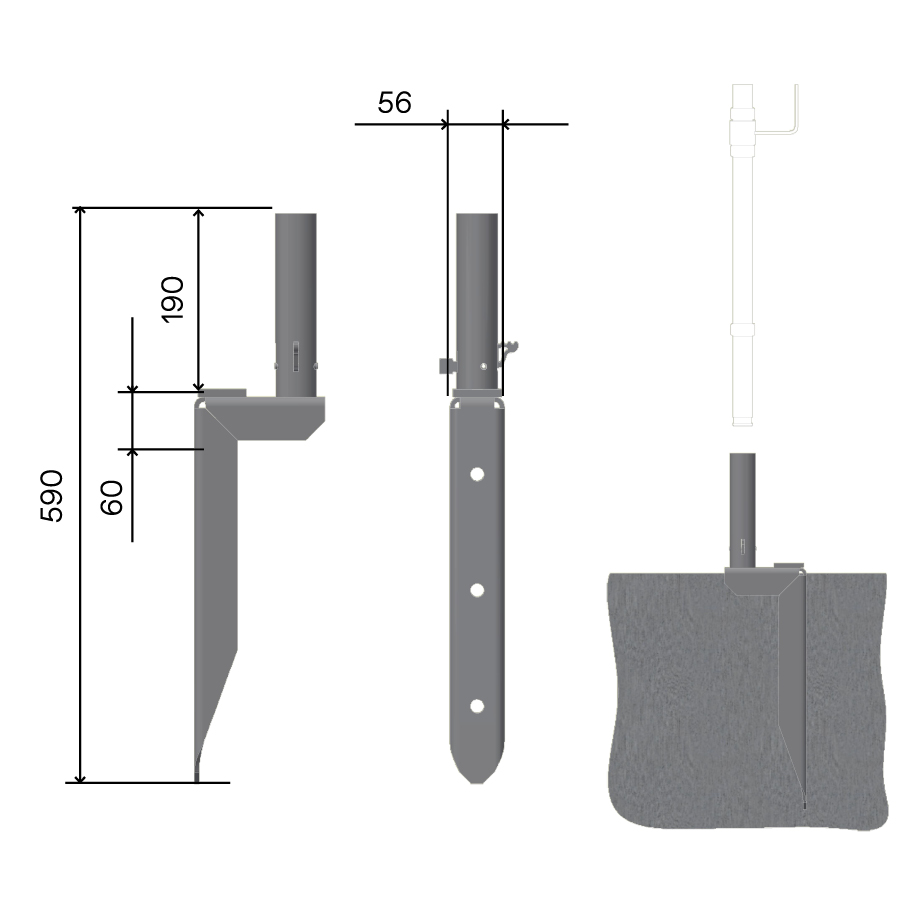

Designed to ensure high resistance to dynamic forces.Application: Assembling the guard rail...

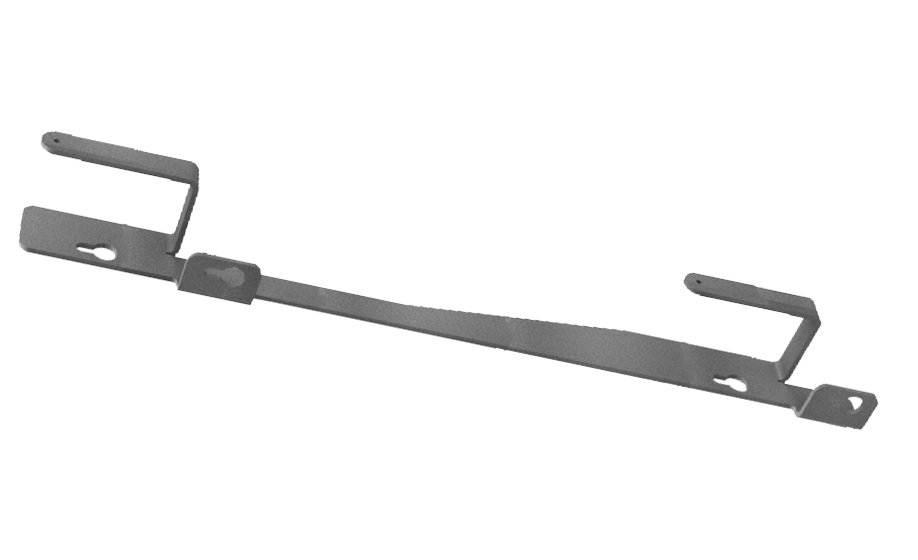

Additional element used with wooden plank protectionApplication: Protecting the plank...

The holders must always be used in sets of two assembled opposite each other.Application:...

Additional element used for barrier protection.Application: Placing barriers directly on...

Additional element used for barrier protection.Application: Placing barriers directly on...

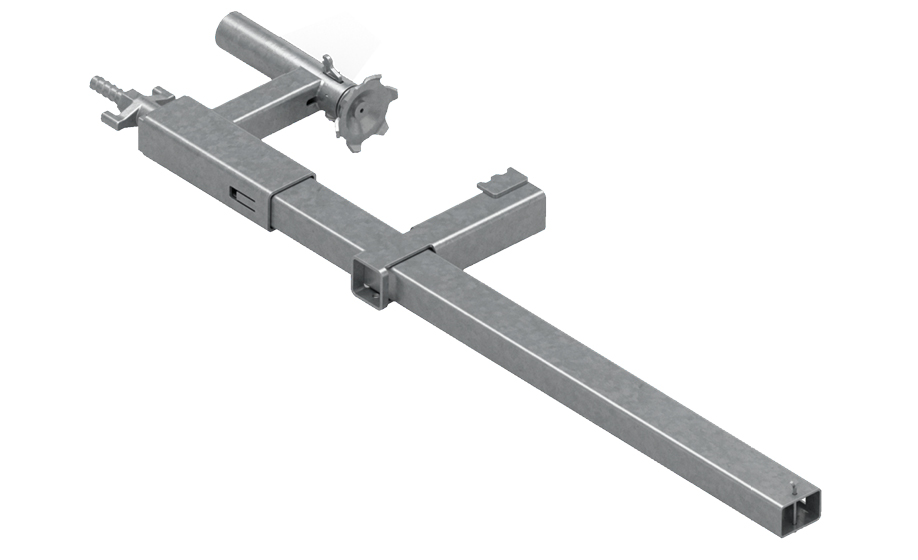

Allows for formwork operations on edges that protrude beyond the outline of the...

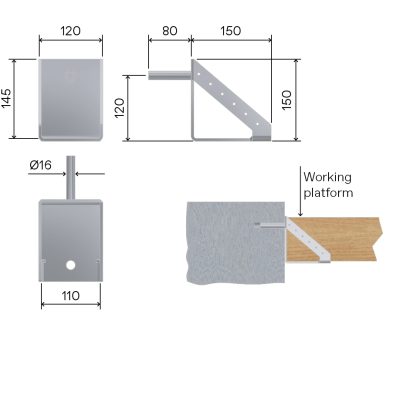

Facade Holder has a simple design that facilitates assembly to steel and concrete structures. The...

Thanks to the integrated construction it ensures better stability of the railing and reduces the...

A base for the horizontal screw-fastened holder EPS-UPZApplication: A foot with standard...

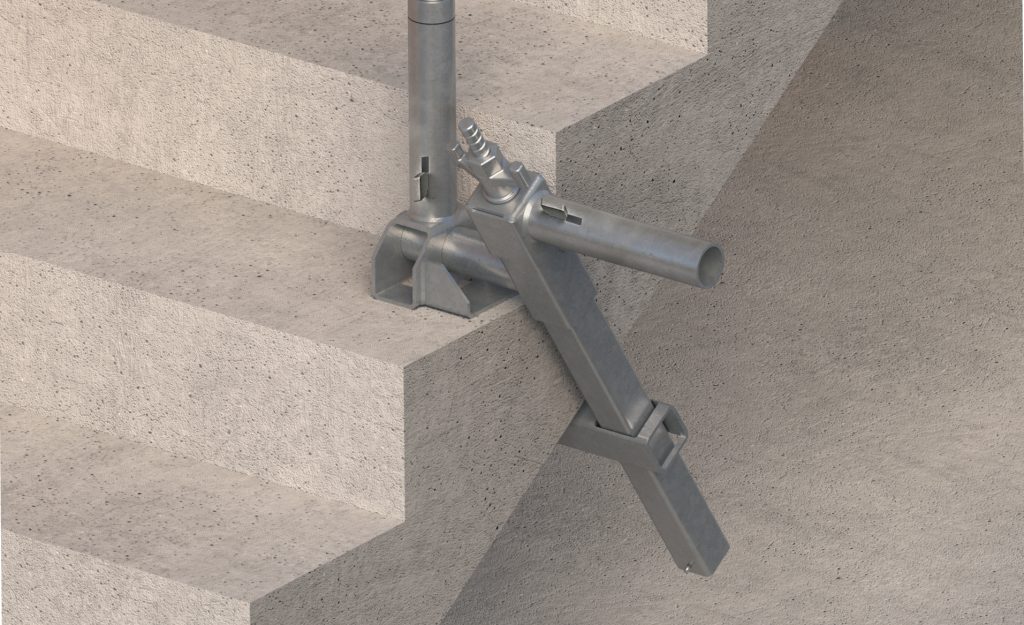

Side stair clamp – ensures stable and secure fixing of barrier to concrete stair flights. It...

The EPS-US3 wall clamp enables the secure installation of railing systems between concrete walls....

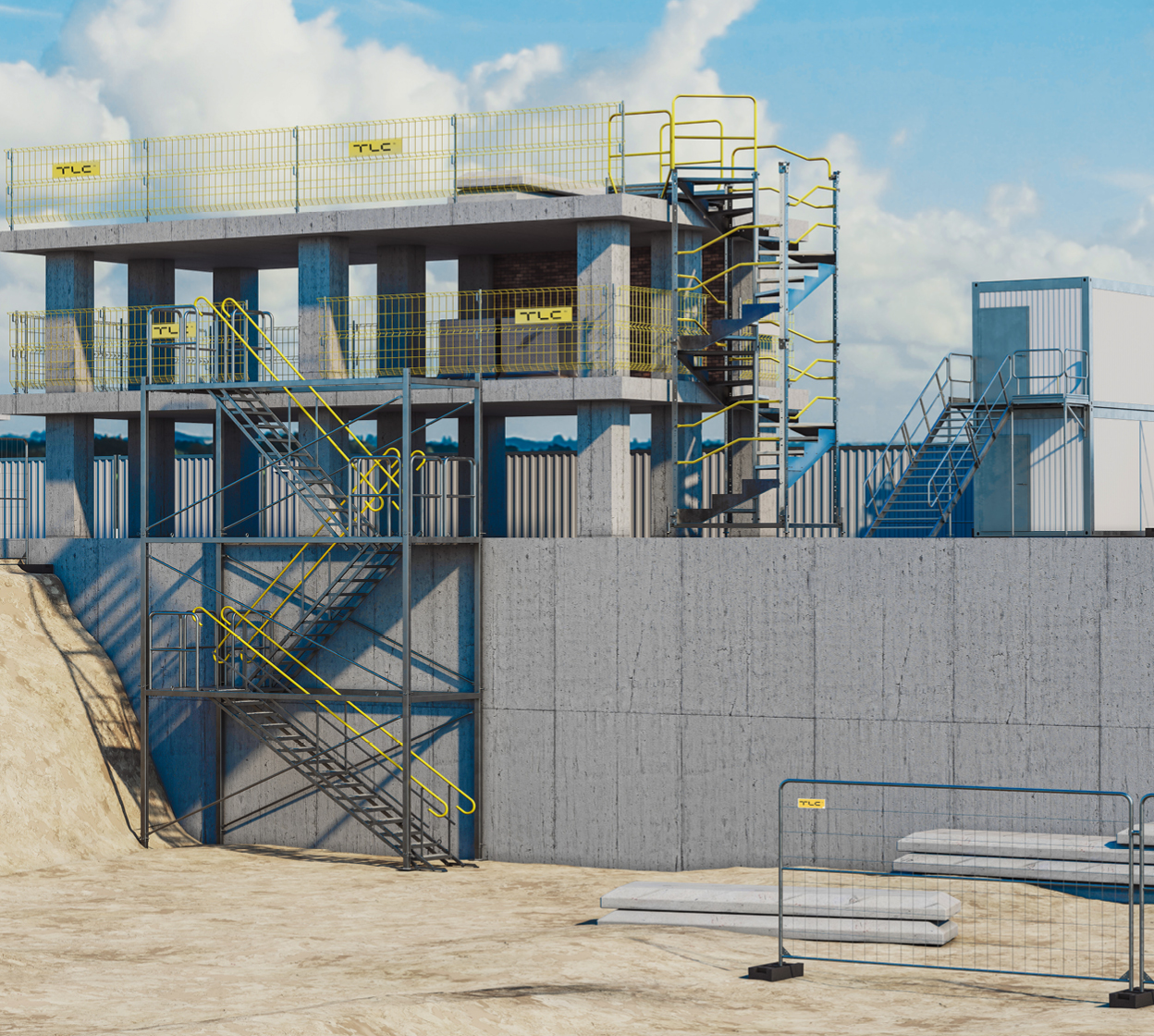

Transport

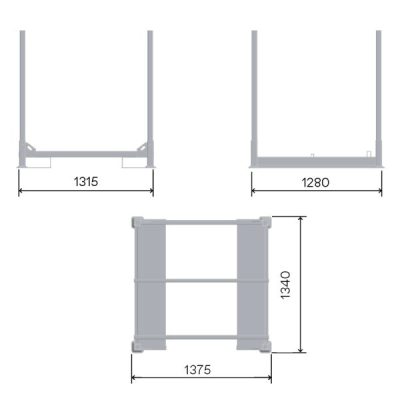

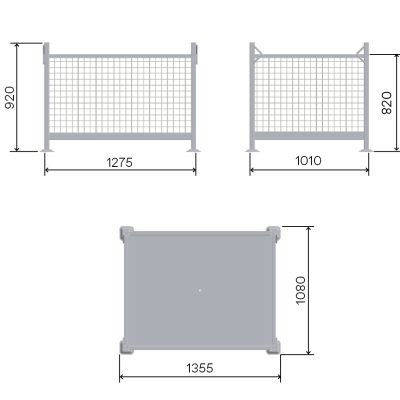

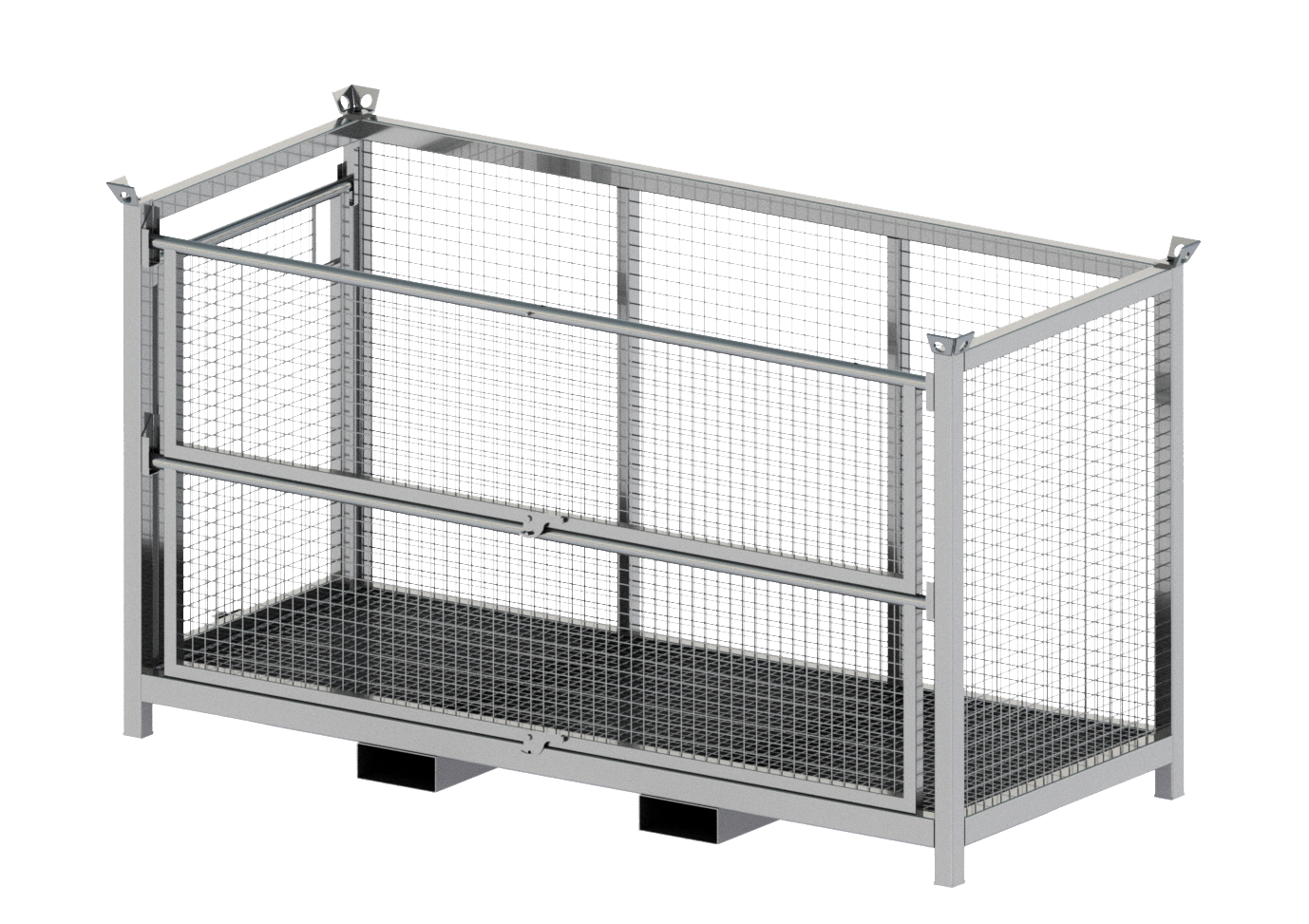

Designed to store mesh panels, planks and EPS-R1750 holder. CapacityEPS-PAN-ECO:...

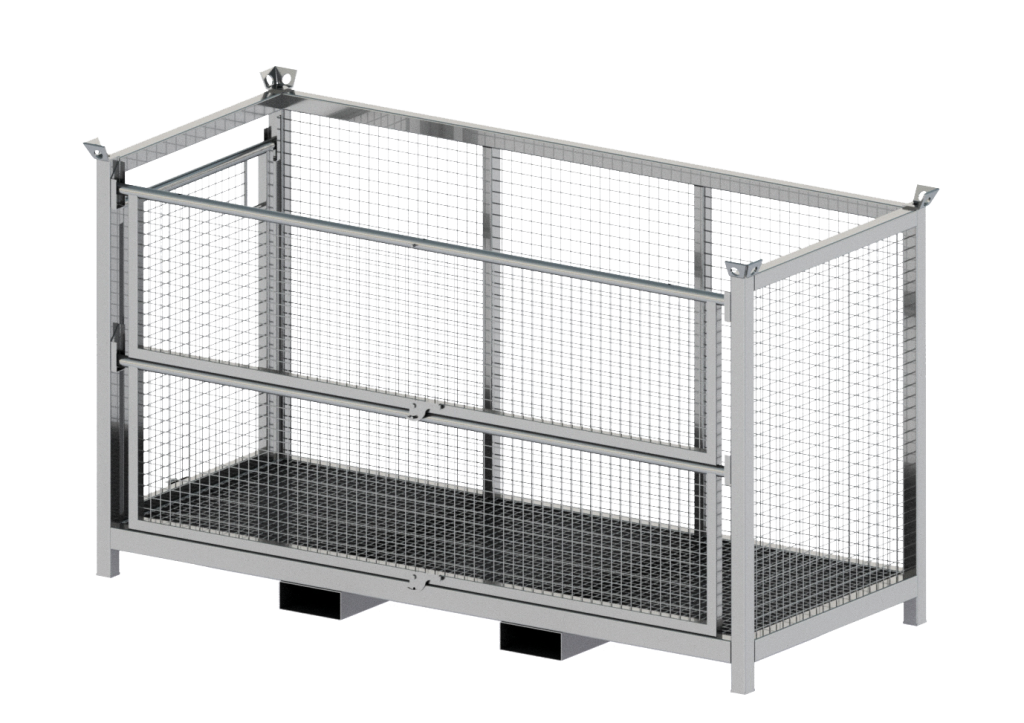

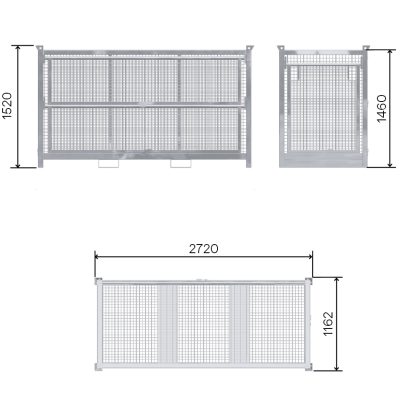

Equipped with upper grips in the corners (for crane transport, stacking) and at the bottom...

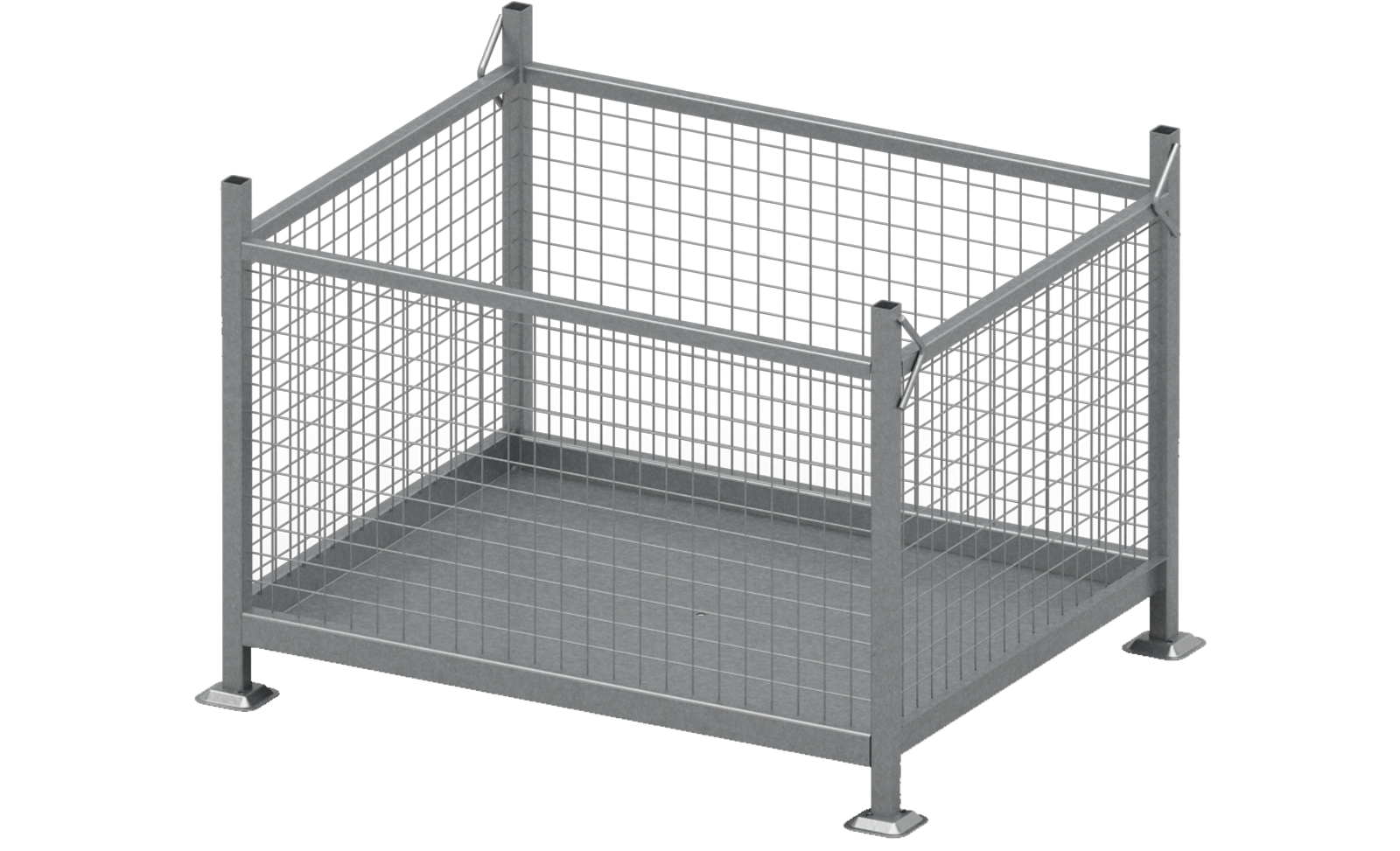

Equipped with upper grips in the corners (for crane transport, stacking) and at the bottom...

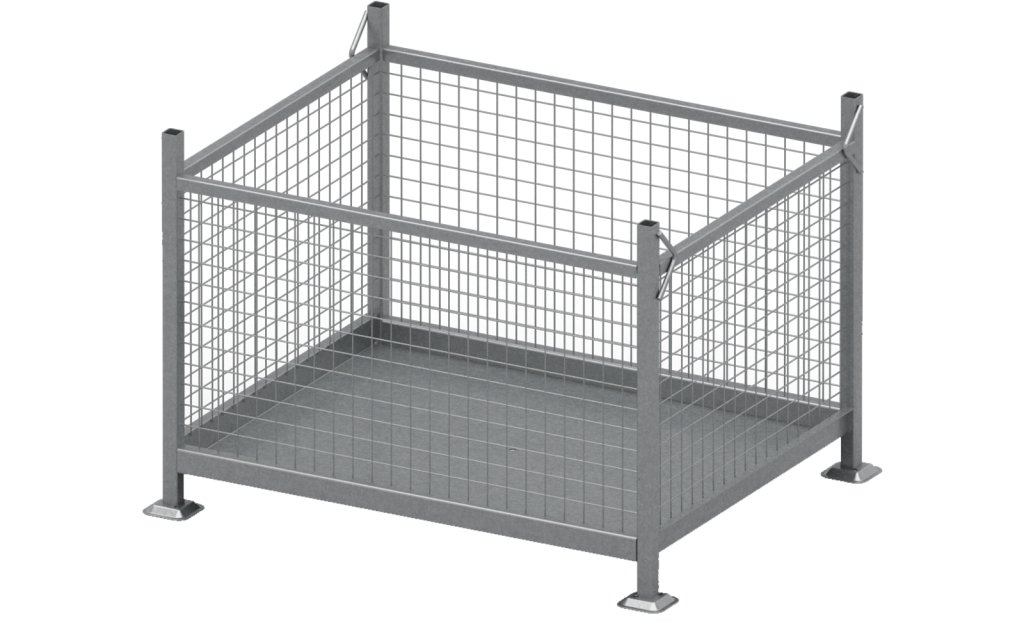

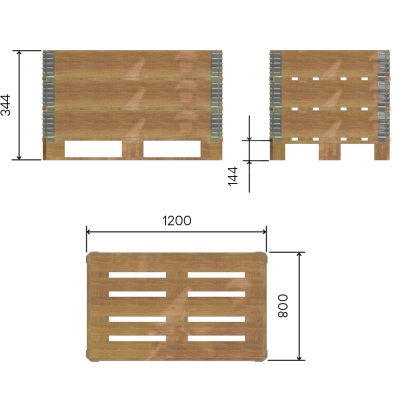

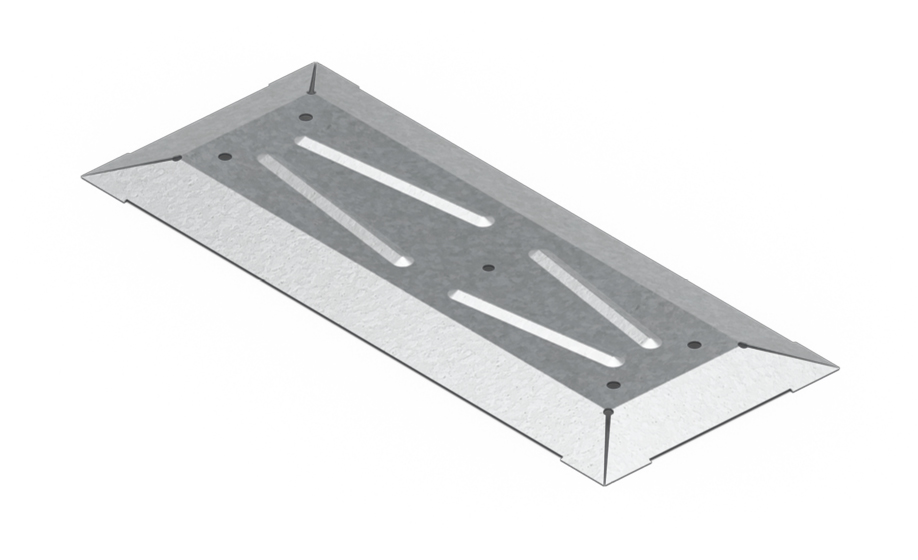

Low cost possibility to store system elements. The pallet can be stacked. The most recommended...

Product materials

Certification

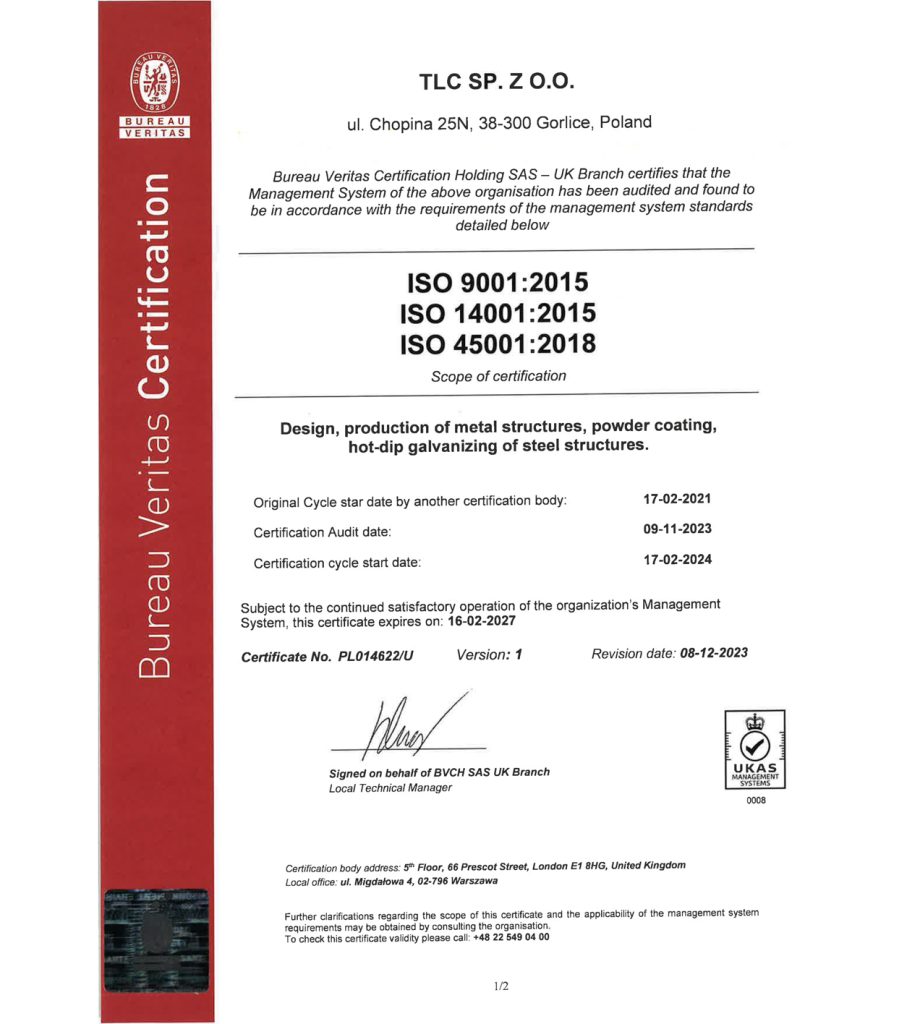

We ensure that all of our products are of the highest quality through compliance with Factory Manufacture Control certification with EN 1090-1:2009+A1:2011, issued by the TÜV SÜD Polska Sp. z o.o. Certification Centre.

We are a manufacturer with a certificate of the Integrated Quality, Environment and Health and Safety Management System according to ISO 9001/ ISO 14001/ ISO 45001 issued by Bureau Veritas Certification.

Our construction products meet the requirements of the European Directive 305/2011 (CPR) for structural steel and aluminum.

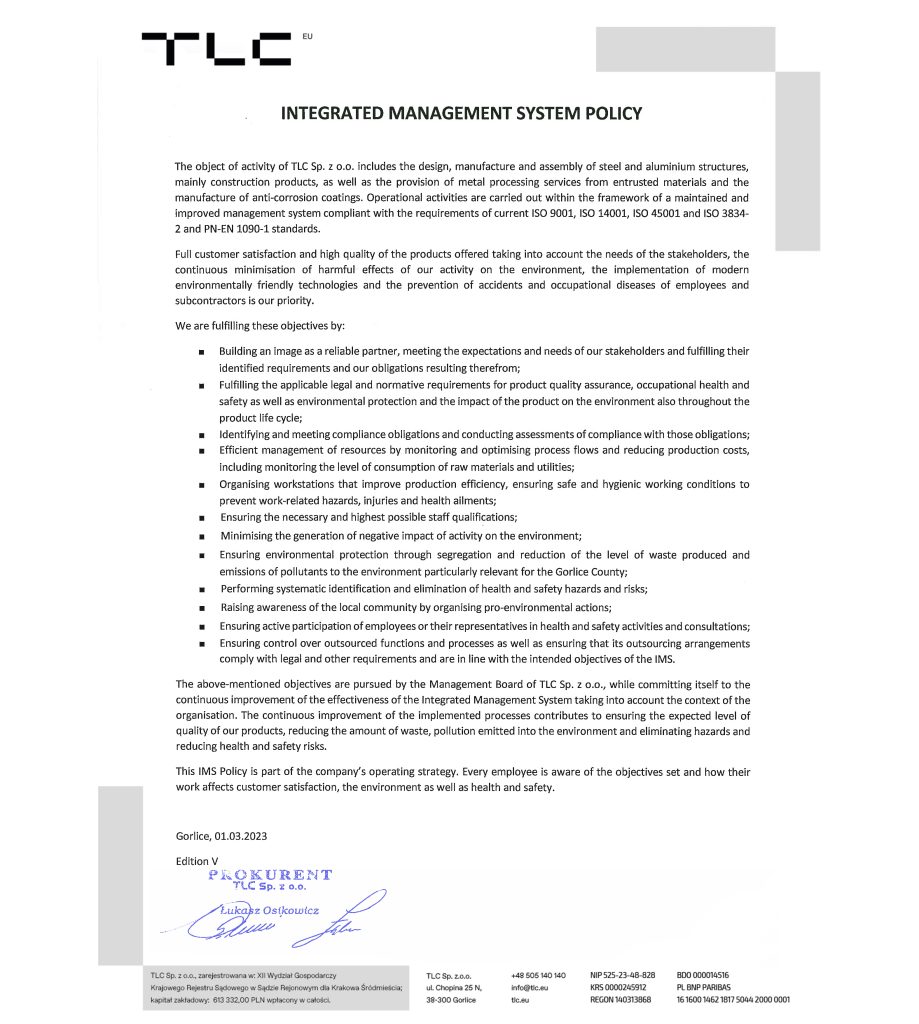

Integrated Management System Policy

Gorlice, 1.05.2023, 5th edition

Design, production of metal structures, powder coating, hot-dip galvanzing of steel structures

Bureau Veritas Certification, ISO 9001:2015; ISO 14001:2015; ISO 45001:2018