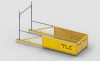

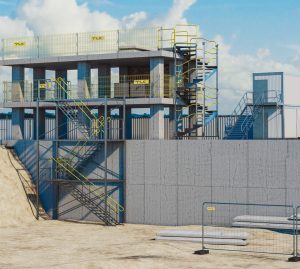

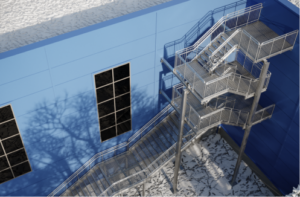

TUP – crane loading platform

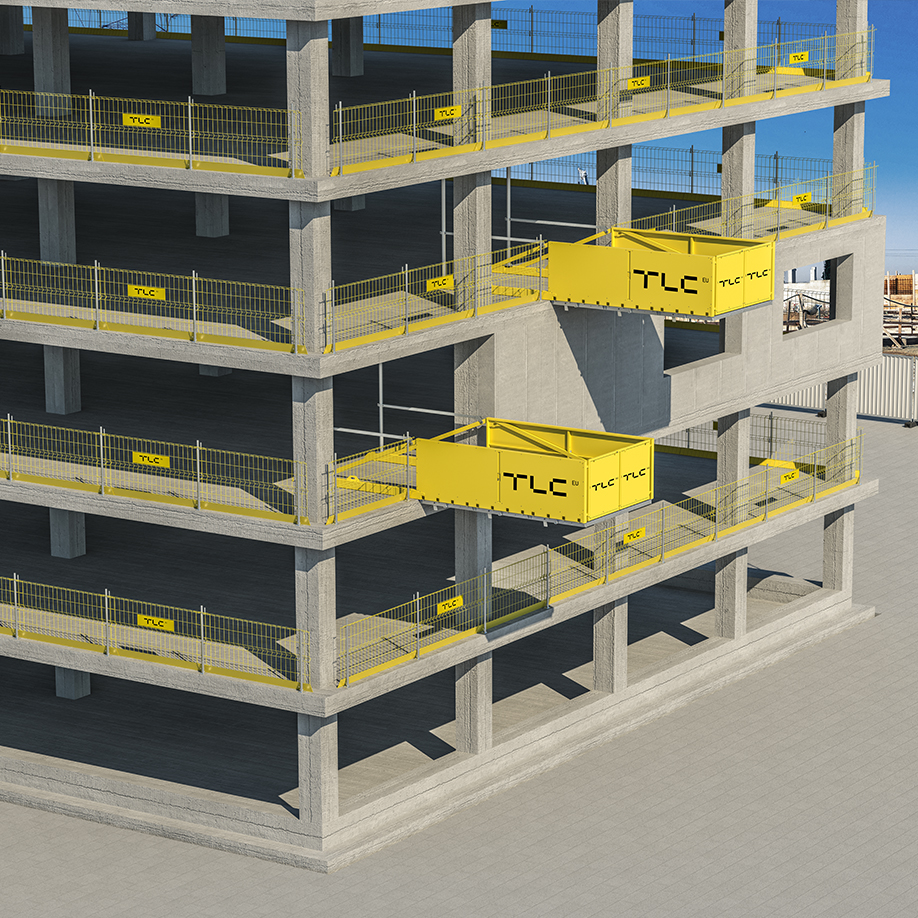

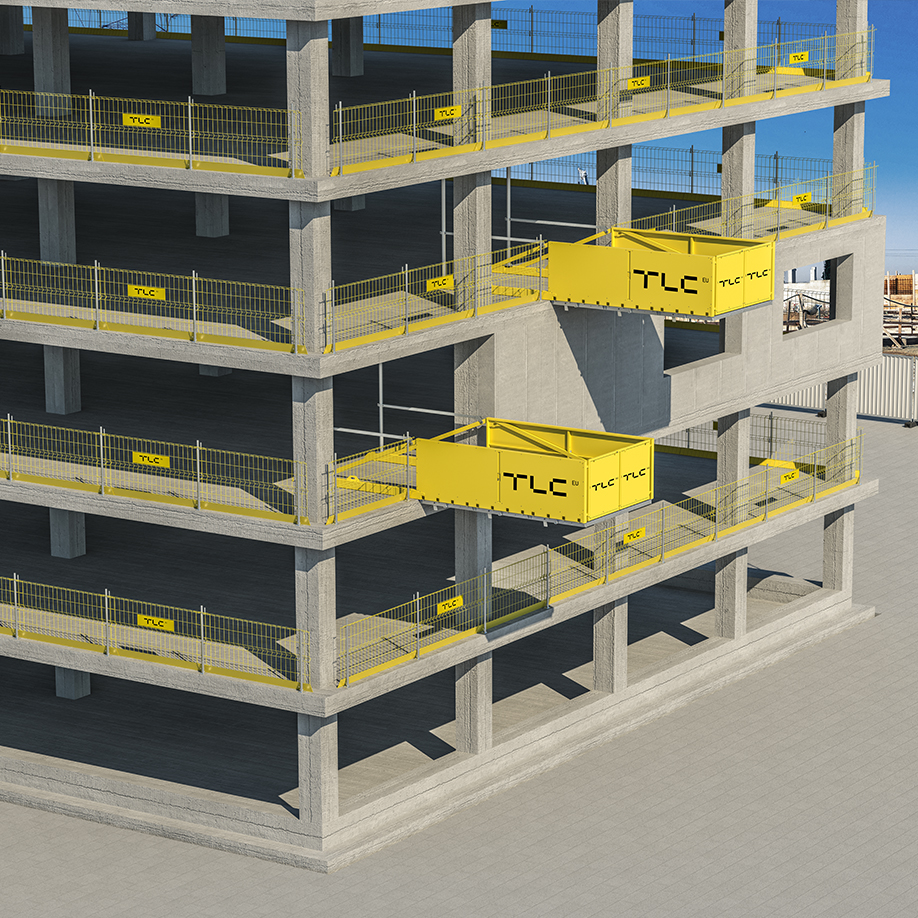

TUP temporary unloading platform is the solution that facilitates transport and safe unloading of materials between building tiers at construction sites.

The unloading platform can also be used as a place to store building materials so they won’t interfere with your construction pans.

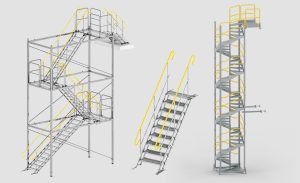

They are available in 3 widths, which allows you to choose the one that fits your current needs best.

One of the key characteristics of TUP temporary unloading platform is their high mobility. The platform is transported in componentry and the bolted together at the construction site offering space-saving and costs reduction in logistics.

Key features of Temporary Unloading Platform TUP – crane loading / cantilever platform

- Maximum allowed platform load: 4000 kg

Our platforms are designed to handle substantial loads, making them suitable for various construction and industrial applications.

- Positive IMBiGS certification for TUP – Compliant with PN-EN 12811-3 standards.

We are proud to announce that our TLC platforms have received a positive result from the IMBiGS Institute, confirming full compliance with the PN-EN 12811-3 standard guidelines. This certification ensures the highest safety and quality standards for our products, giving our customers the confidence they need when working at height. - Available in three widths

Choose from three available platform widths to suit your specific project needs:

→ 1.2 meters → 1.5 meters → 2.2 meters

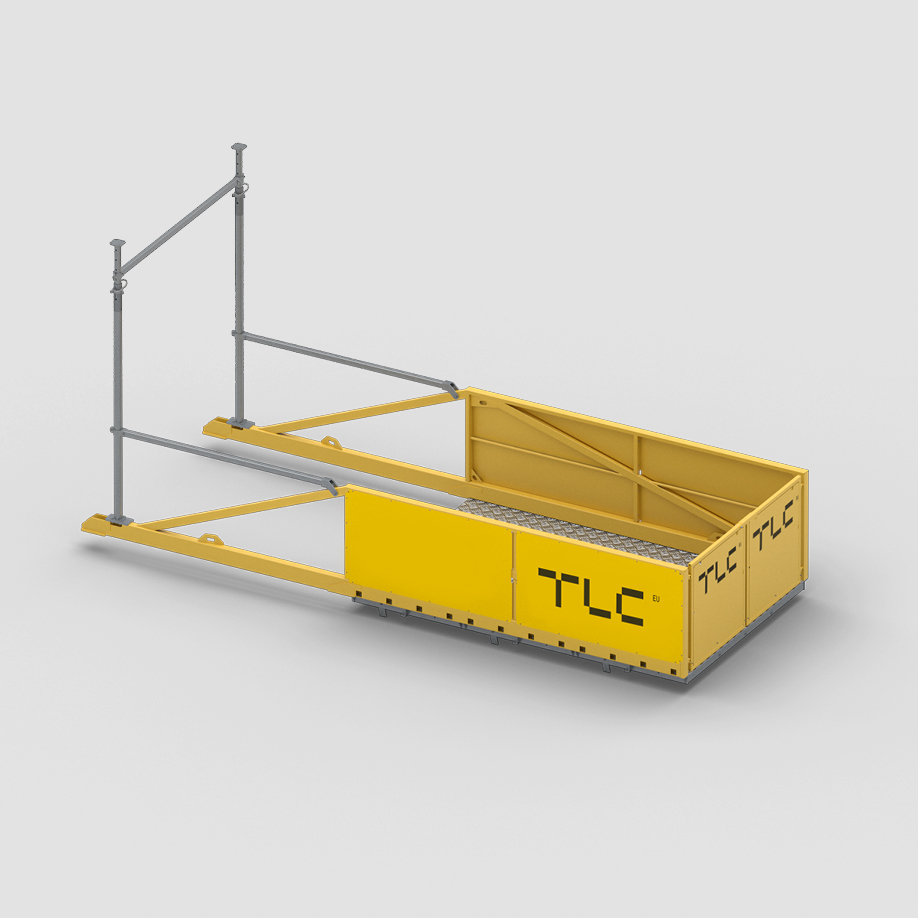

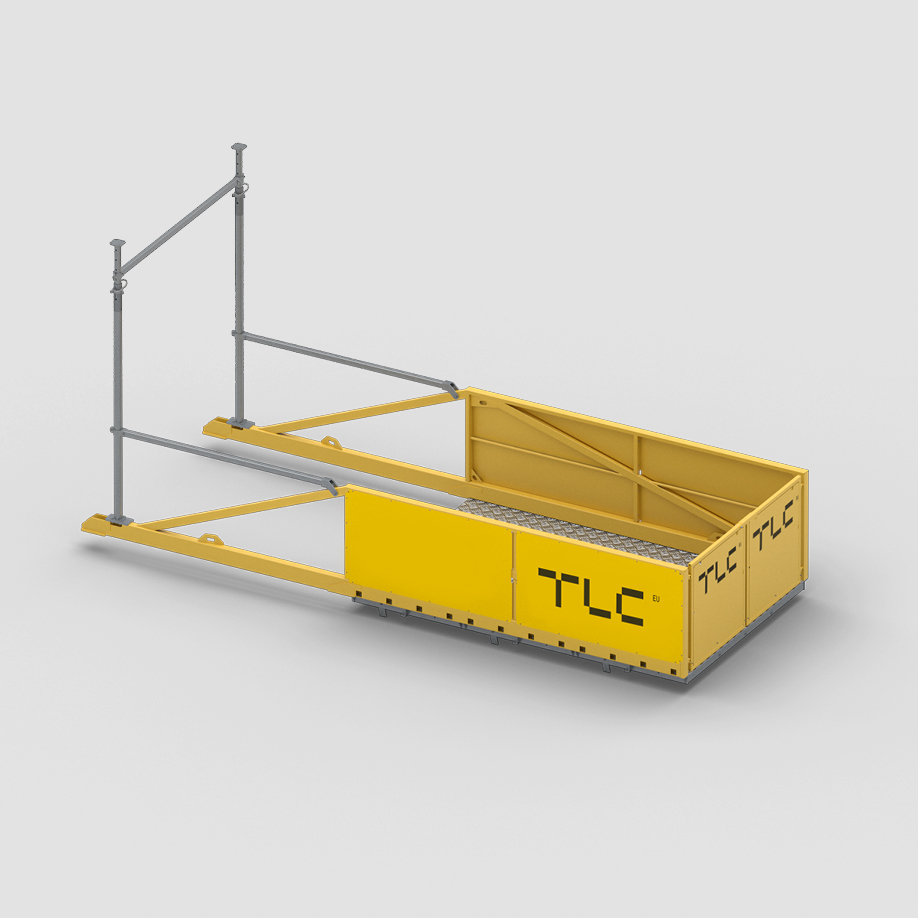

- Checker plate lining for anti-skid protection

The platform surface features achecker plate lining that effectively prevents skidding, enhancing safety for workers operating in various weather conditions. - Safety harness holders for enhanced security

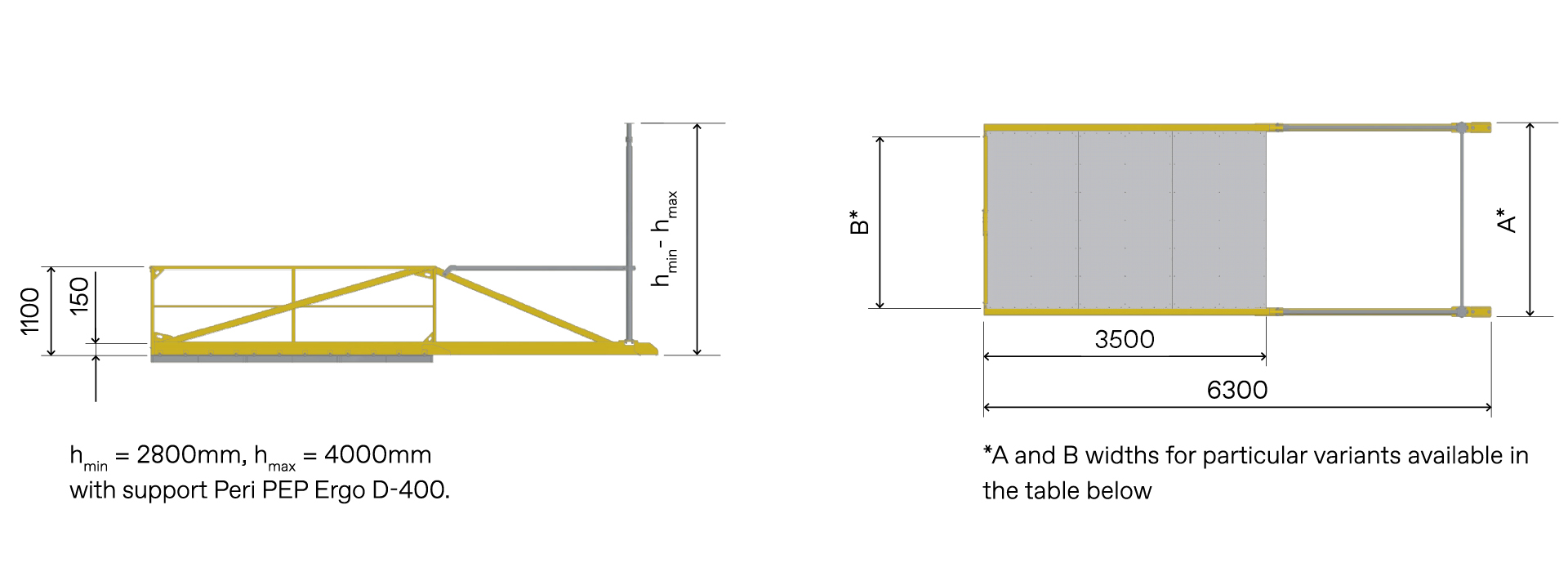

Integrated safety harness holders provide additional security, ensuring that workers are able to safely attach themselves to the platform, reducing the risk of falls. - Two assembly methods for versatile use

Our platform design allows for two flexible assembly methods, making it possible to use the platform both between tiers of scaffolding and directly on the roof, offering versatility for different construction projects.

- Efficient bolted construction

The platform is designed to be bolted together from individual components, which makes it easier to handle during logistics, assembly, and disassembly. This modular design also helps to reduce transport costs, as it can be compactly packed and easily moved to and from job sites. - Anti-corrosion protection

For long-lasting durability, our platforms are coated with anti-corrosive protection through hot-dip galvanization according to the PN-EN ISO 1461 standard, or finished with powder painting to provide a protective, aesthetic finish. - Customizable advertising cover option

In addition to being functional, our platforms can also serve as a branding tool. We offer the possibility to attach an advertising cover with any custom design or overprint, allowing your company to stand out while ensuring safety on-site. - Crane loading

- Cantilever platform

| Article no. | TUP-1.25 | TUP-1.5 | TUP-2.2 |

| Weight [kg] | 751 without supports, 814 with supports | 810 without supports, 863 with supports | 960 without supports, 1013 with supports |

| Platform width [A] | 1456 | 1706 | 2403 |

| Unloading area width [B] | 1250 | 1500 | 2200 |

| Intended use | The platform functions as a finished solution ensuring proper unloading area for materials transported using cranes and other lifting equipment. | ||

| Materials | S235/S355 steel, aluminum | S235/S355 steel, aluminum | S235/S355 steel, aluminum |

Product materials

Technical Documentation

Certification

We ensure that all of our products are of the highest quality through compliance with Factory Manufacture Control certification with EN 1090-1:2009+A1:2011, issued by the TÜV SÜD Polska Sp. z o.o. Certification Centre.

We are a manufacturer with a certificate of the Integrated Quality, Environment and Health and Safety Management System according to ISO 9001/ ISO 14001/ ISO 45001 issued by Bureau Veritas Certification.

Our construction products meet the requirements of the European Directive 305/2011 (CPR) for structural steel and aluminum.

Integrated Management System Policy

Gorlice, 1.05.2023, 5th edition

Design, production of metal structures, powder coating, hot-dip galvanzing of steel structures

Bureau Veritas Certification, ISO 9001:2015; ISO 14001:2015; ISO 45001:2018